-

Dec 24, 2025

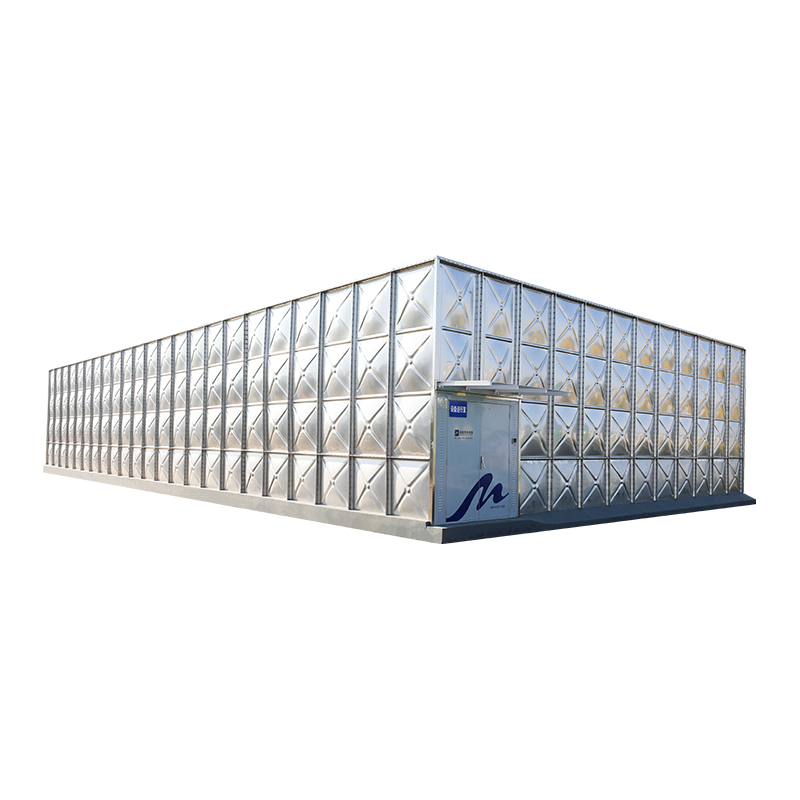

Comprehensive Guide to Sectional Cold Water Storage TanksDefinition of Sectional Cold Water Storage Tanks: Modular, panel-based water holding systems that can be assembled onsite to meet specific capacity re... -

Dec 24, 2025

Comprehensive Guide to Sewage Centrifugal Pump SolutionsIntroduction to Sewage Centrifugal Pump The Sewage Centrifugal Pump is a critical component in modern water treatment and wastewater management. Thes... -

Dec 16, 2025

The Ultimate Guide to Custom Stainless Steel Water Tanks: Engineering, Applications, and Smart SolutionsIn the realm of water storage and management, the choice of tank material and design is paramount for ensuring longevity, hygiene, and system efficien... -

Dec 16, 2025

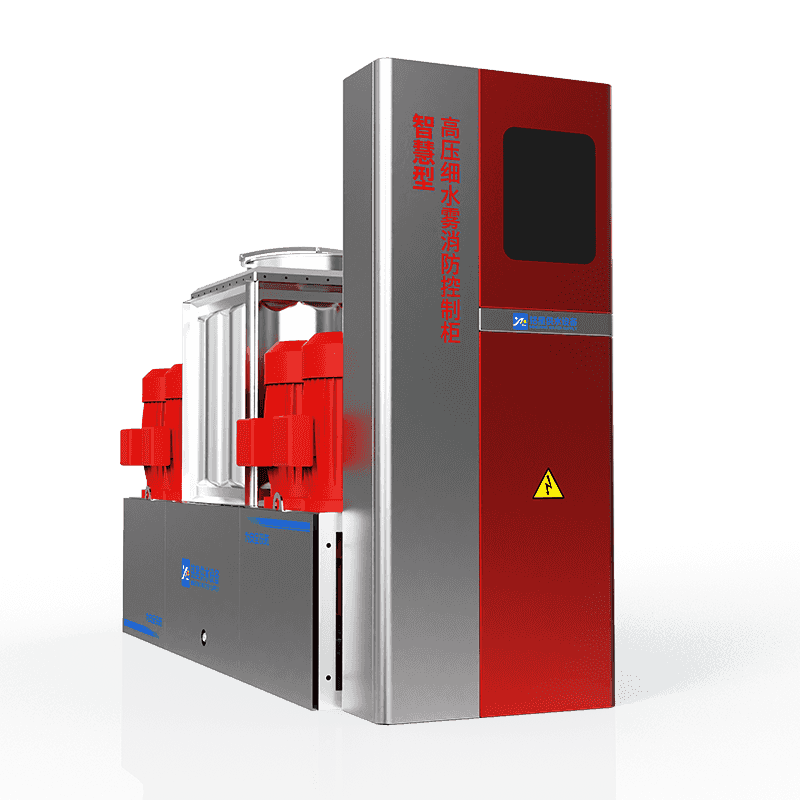

Understanding the Water mist firefighting system: Technology, Design, and BenefitsIntroduction to Water mist firefighting system The Water mist firefighting system uses very fine water droplets to suppress or extinguish fire swiftl... -

Dec 12, 2025

High-Pressure Fine Water Mist (H-FWM): Smart Suppression Solutions for High-Risk Industrial and Marine AssetsThe Breakthrough of High-Pressure Fine Water Mist Technology The High-Pressure Fine Water Mist (H-FWM) Fire Suppression System is the apex of modern f... -

Dec 12, 2025

Understanding Arc Rib Assembly Bolted Type Sectional Water TankWhat Is an Arc Rib Assembly Bolted Type Sectional Water Tank Core Structural Features and Engineering Principles The Arc Rib Assembly Bolted Type Sect... -

Dec 05, 2025

How Sectional Tanks Transform Water InfrastructureUnderstanding Sectional Water Tank Technology Key Features of Modern Sectional Tanks The modern Sectional Water Tank has become one of the most adapta... -

Dec 05, 2025

Water Mist Cuts Damage, Saves Lives: The Future of Fire ProtectionIn the evolving landscape of fire safety, the traditional methods, while effective, often come with the inherent cost of significant water damage to ... -

Nov 26, 2025

Next-Gen Protection: Why Experts Choose High Pressure Water Mist.The landscape of fire safety is continually evolving, driven by the need for more efficient, less damaging, and environmentally sound solutions. At th... -

Nov 24, 2025

Why Modular Water Storage Tanks Are the Future of Efficient Water ManagementThe Rising Demand for Advanced Water Storage Solutions As global water scarcity becomes an increasingly pressing issue, the need for innovative water ... -

Nov 21, 2025

Comprehensive Guide to the Arc Rib Assembly Bolted Type Sectional Water Tank: Design, Advantages, and Smart Water IntegrationThe Foundation of Modern Water Management Defining the Arc Rib Assembly Bolted Type Sectional Water Tank The Arc Rib Assembly Bolted Type Sectional W... -

Nov 19, 2025

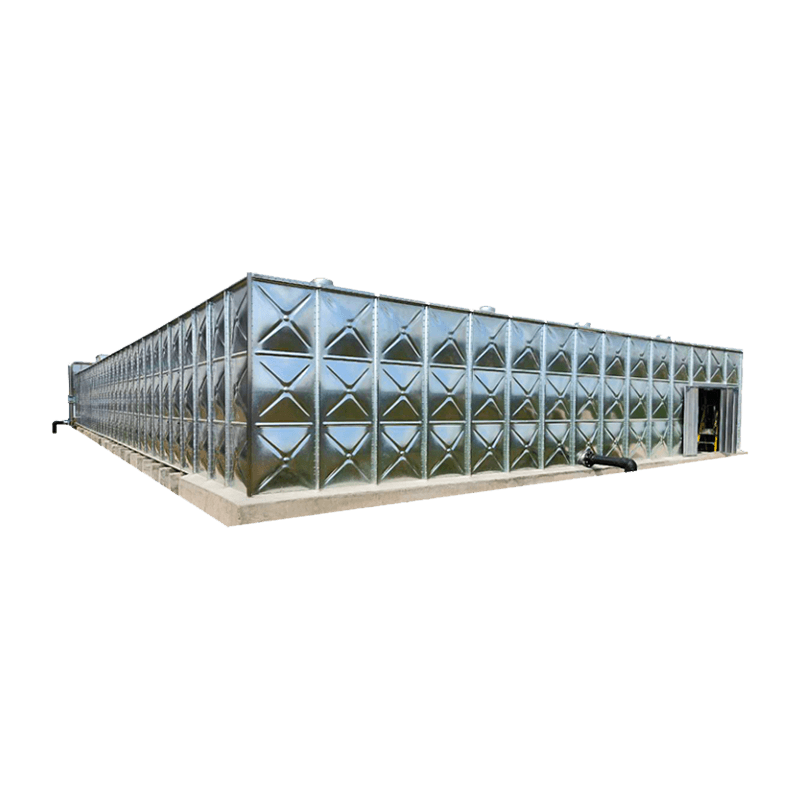

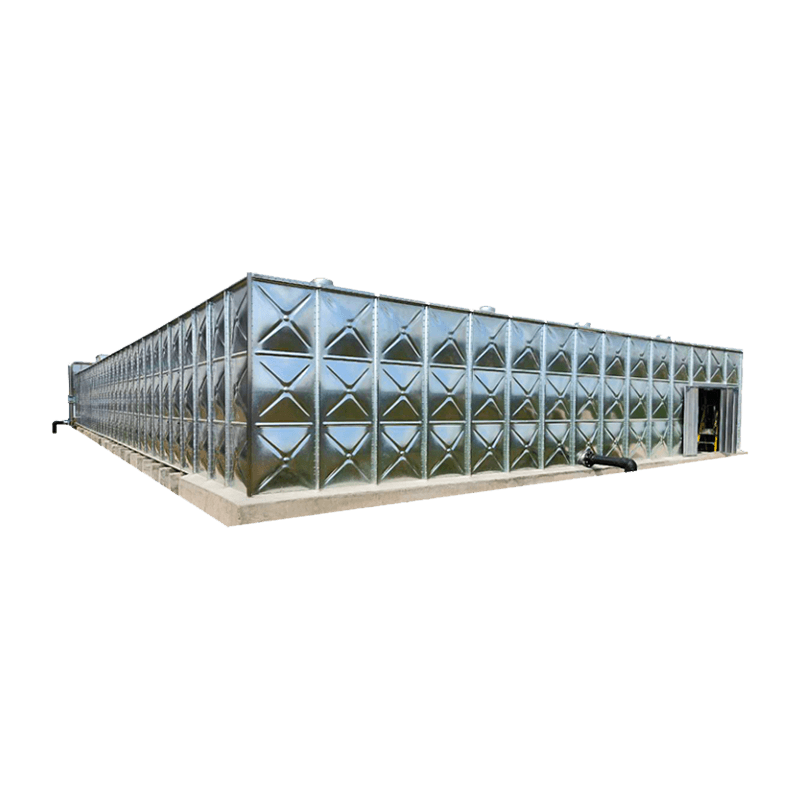

A Comprehensive Guide to Hot Dipped Galvanized Water TanksIn the world of water storage and supply, selecting the right tank is paramount for longevity, safety, and efficiency. The hot dipped galvanized water...