-

Dec 12, 2025

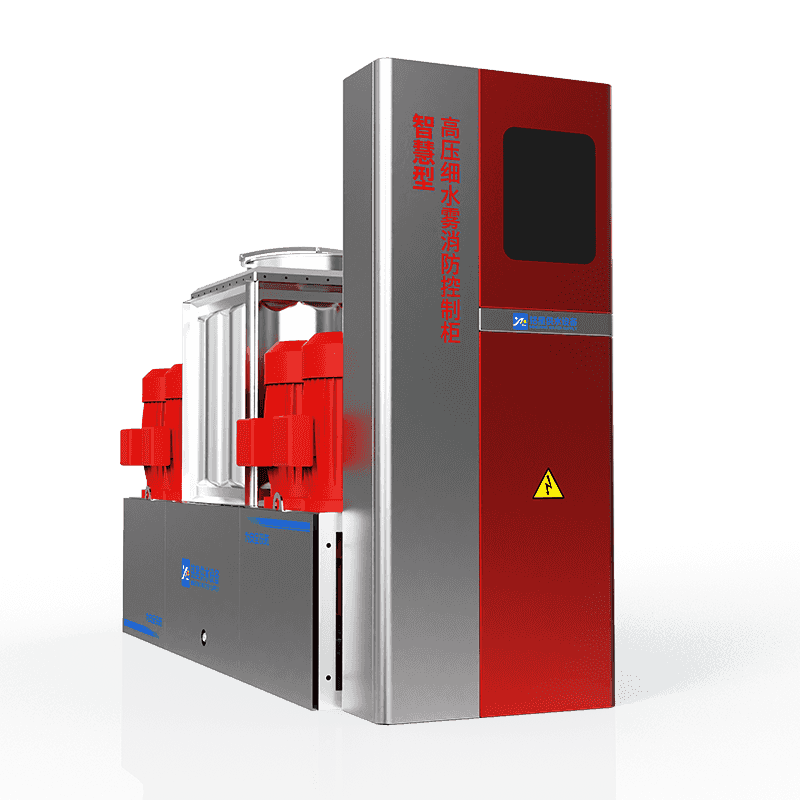

High-Pressure Fine Water Mist (H-FWM): Smart Suppression Solutions for High-Risk Industrial and Marine AssetsThe Breakthrough of High-Pressure Fine Water Mist Technology The High-Pressure Fine Water Mist (H-FWM) Fire Suppression System is the apex of modern f... -

Dec 12, 2025

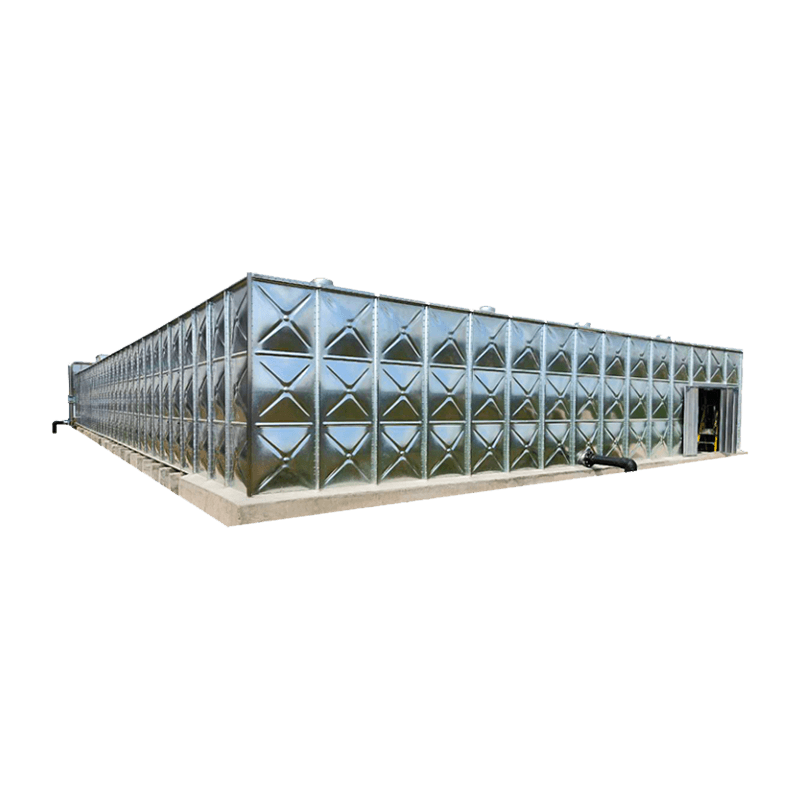

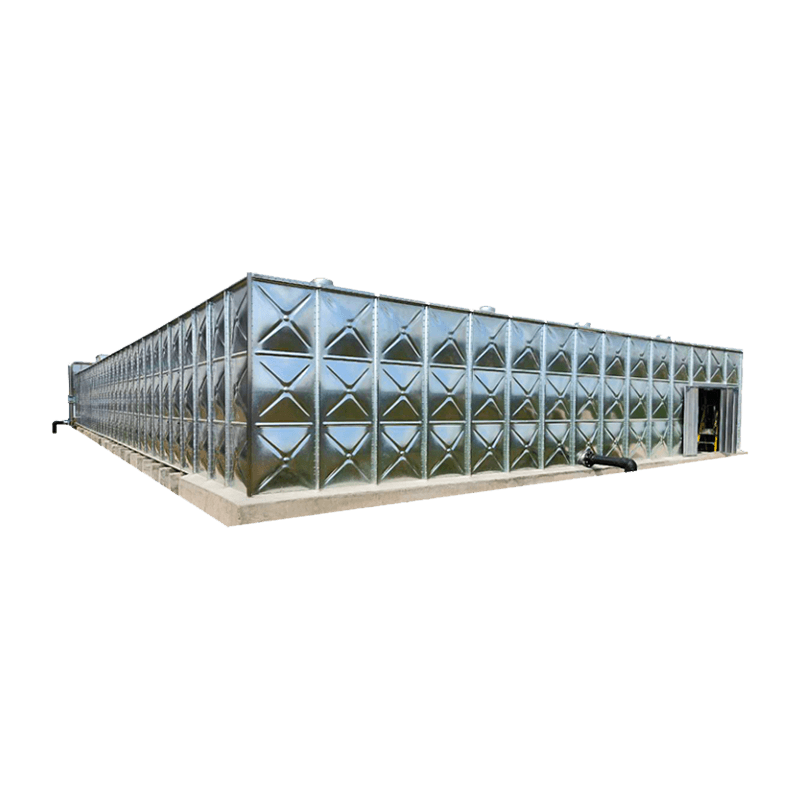

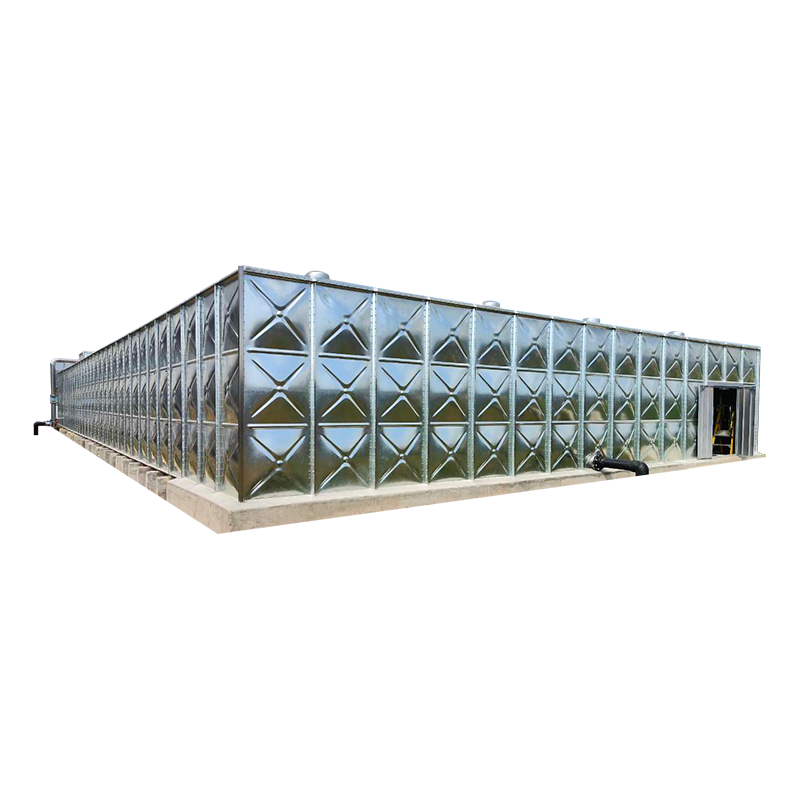

Understanding Arc Rib Assembly Bolted Type Sectional Water TankWhat Is an Arc Rib Assembly Bolted Type Sectional Water Tank Core Structural Features and Engineering Principles The Arc Rib Assembly Bolted Type Sect... -

Dec 05, 2025

How Sectional Tanks Transform Water InfrastructureUnderstanding Sectional Water Tank Technology Key Features of Modern Sectional Tanks The modern Sectional Water Tank has become one of the most adapta... -

Dec 05, 2025

Water Mist Cuts Damage, Saves Lives: The Future of Fire ProtectionIn the evolving landscape of fire safety, the traditional methods, while effective, often come with the inherent cost of significant water damage to ... -

Nov 26, 2025

Next-Gen Protection: Why Experts Choose High Pressure Water Mist.The landscape of fire safety is continually evolving, driven by the need for more efficient, less damaging, and environmentally sound solutions. At th... -

Nov 24, 2025

Why Modular Water Storage Tanks Are the Future of Efficient Water ManagementThe Rising Demand for Advanced Water Storage Solutions As global water scarcity becomes an increasingly pressing issue, the need for innovative water ... -

Nov 21, 2025

Comprehensive Guide to the Arc Rib Assembly Bolted Type Sectional Water Tank: Design, Advantages, and Smart Water IntegrationThe Foundation of Modern Water Management Defining the Arc Rib Assembly Bolted Type Sectional Water Tank The Arc Rib Assembly Bolted Type Sectional W... -

Nov 19, 2025

A Comprehensive Guide to Hot Dipped Galvanized Water TanksIn the world of water storage and supply, selecting the right tank is paramount for longevity, safety, and efficiency. The hot dipped galvanized water... -

Nov 13, 2025

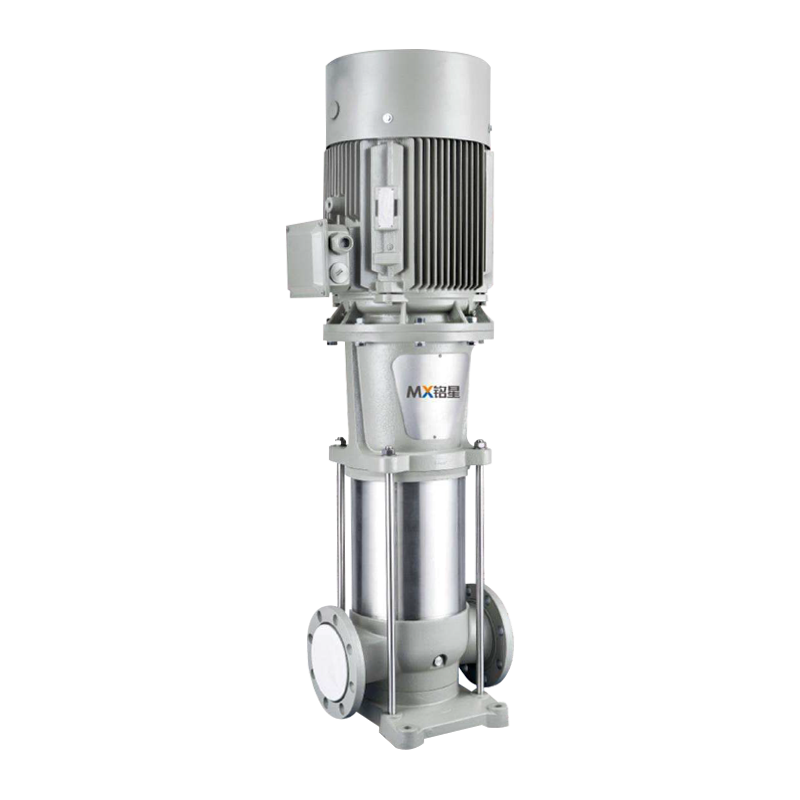

Horizontal Multi-Stage Centrifugal Pumps See Growing Adoption Across Water Supply and Processing SectorsUnderstanding the Mechanism of Multi-Stage Pump Operation The operational principle of the horizontal multi-stage centrifugal pump is foundational to ... -

Nov 11, 2025

The Ultimate Guide to Choosing a hot dipped galvanized water tank for Smart Water Supply SystemsUnderstanding the hot dipped galvanized water tank Definition & manufacturing process A hot dipped galvanized water tank is a steel-panel-based s... -

Nov 05, 2025

The Low-Maintenance Centrifugal Pump for Abrasive & Corrosive SlurriesUnderstanding the Challenges of Pumping Abrasive and Corrosive Slurries Industrial operations dealing with abrasive and corrosive slurries face signif... -

Nov 05, 2025

Comparing Modular Fire-Fighting Water Tanks vs Traditional Steel Water Tanks: Which Is Better?An Overview of Fire-Fighting Water Storage Solutions The selection of an appropriate water storage solution is a critical decision for fire safety pla...