Nov 24, 2025

As global water scarcity becomes an increasingly pressing issue, the need for innovative water storage solutions has never been more critical. Traditional water storage methods often fall short in addressing modern challenges such as space constraints, environmental concerns, and evolving infrastructure requirements. This is where modular water storage tanks emerge as a transformative technology, offering unprecedented flexibility and efficiency in water management systems across various sectors.

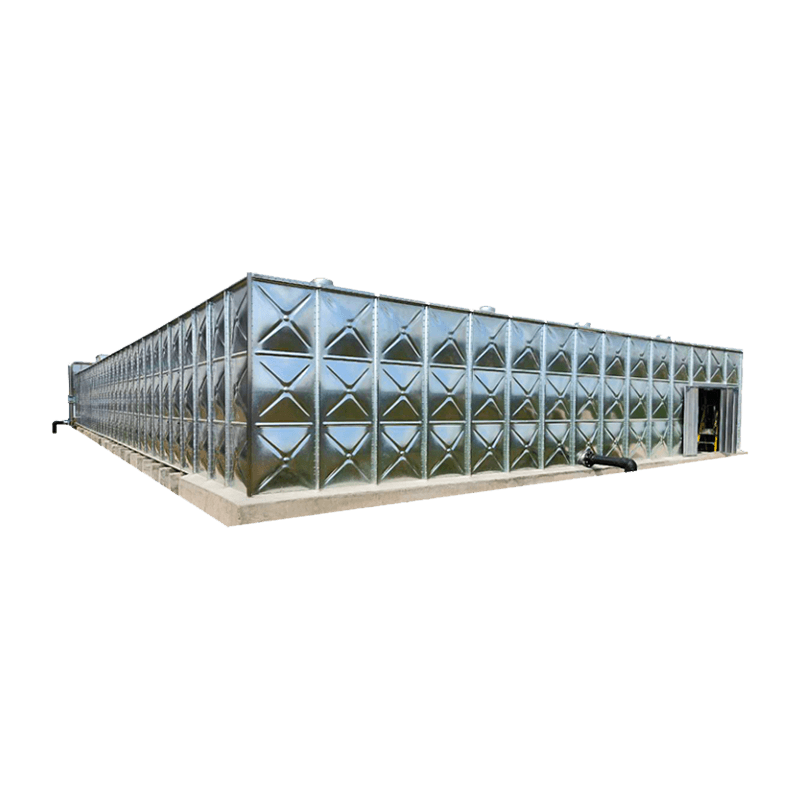

Modular water storage tanks represent a significant advancement in water containment technology. Unlike conventional monolithic tanks, these systems consist of interconnected units that can be configured to meet specific capacity requirements and spatial constraints. The fundamental principle behind modular tanks lies in their ability to be assembled, disassembled, and reconfigured as needs change, providing a dynamic solution that grows with your requirements.

The engineering behind modular water storage tanks incorporates several sophisticated elements that contribute to their superior performance and reliability. Understanding these components is essential for appreciating why these systems represent such a significant improvement over traditional alternatives.

Modern modular tanks utilize high-grade materials specifically engineered for water storage applications. These materials must meet rigorous standards for durability, chemical resistance, and environmental safety. The structural framework is designed to withstand various loads including hydrostatic pressure, environmental forces, and potential ground movement, ensuring long-term reliability and safety.

The interconnection mechanism between individual modules represents one of the most crucial aspects of these systems. Advanced sealing technologies and connection methods ensure watertight integrity while allowing for flexibility and movement. These connection systems are designed for easy assembly while maintaining the structural integrity of the complete storage system.

Rainwater harvesting has gained significant traction as a sustainable practice for both residential and commercial applications. Modular water storage tanks offer distinct advantages that make them particularly well-suited for rainwater collection systems, addressing many limitations associated with traditional rainwater storage methods.

One of the most significant challenges in rainwater harvesting is finding adequate space for storage tanks, particularly in urban environments or properties with limited area. Modular systems excel in this regard by offering unparalleled flexibility in configuration and placement. Unlike rigid, pre-formed tanks that require specific footprints, modular tanks can be adapted to fit available spaces, including irregularly shaped areas or locations with access constraints.

The scalable nature of modular water tanks allows for adaptive capacity management, meaning storage volume can be increased or decreased based on seasonal requirements or changing water needs. This eliminates the common problem of over-investing in storage capacity or, conversely, having insufficient storage during periods of high rainfall. The ability to precisely match storage capacity to actual requirements represents both an economic and functional advantage that fixed tanks cannot provide.

Maintaining water quality in rainwater storage systems presents unique challenges that modular tanks effectively address through intelligent design features. The materials used in modular tank construction are specifically selected to prevent contamination and inhibit biological growth, ensuring stored rainwater remains suitable for its intended uses.

When evaluating water storage options for rainwater harvesting, understanding how different systems preserve water quality is essential. The following comparison highlights key differences between modular tanks and traditional alternatives:

Modular tanks typically incorporate advanced lining materials that are non-porous and resistant to microbial colonization, whereas traditional concrete tanks can develop cracks and harbor bacteria. Additionally, modular systems often include integrated access points for cleaning and maintenance, which are frequently overlooked in conventional tank designs. The modular approach also allows for easier inspection of all internal surfaces, enabling proactive maintenance that prevents water quality degradation.

| Feature | Modular Tanks | Traditional Tanks |

|---|---|---|

| Material Porosity | Non-porous materials prevent bacterial infiltration | Porous materials can harbor microorganisms |

| Cleaning Accessibility | Multiple access points for comprehensive cleaning | Limited access makes thorough cleaning difficult |

| Inspection Capability | Designed for easy visual inspection of all components | Limited visibility into tank interior conditions |

| Chemical Leaching | Materials certified for potable water storage | Some materials may leach chemicals over time |

Industrial operations face unique water storage challenges that extend beyond simple capacity requirements. Factors such as water quality specifications, regulatory compliance, operational continuity, and total cost of ownership must all be considered when selecting storage solutions. Modular water tanks offer compelling economic advantages that make them increasingly preferred for industrial applications.

The financial benefits of modular water storage systems extend well beyond their initial purchase price. While traditional storage solutions often require significant upfront investment in site preparation, specialized construction, and custom fabrication, modular systems utilize standardized components that substantially reduce these initial costs. Additionally, the scalability of modular tanks means industrial facilities can match their investment to current needs while preserving the option for future expansion.

Evaluating the true cost of water storage solutions requires considering expenses across the entire lifecycle of the system. This comprehensive analysis reveals why modular tanks often represent the most economically sound choice for industrial applications despite potential misconceptions about their long-term value.

Traditional concrete tanks, while seemingly durable, often incur significant maintenance costs due to cracking, seepage, and structural degradation over time. Steel tanks face challenges with corrosion that necessitate regular inspection, protective coatings, and eventual replacement. In contrast, modular tanks constructed with modern engineered materials demonstrate exceptional resistance to environmental degradation, resulting in lower maintenance requirements and extended service life.

| Cost Factor | Modular Tanks | Traditional Concrete Tanks | Traditional Steel Tanks |

|---|---|---|---|

| Initial Installation | Moderate cost with standardized components | High cost due to custom construction | Variable cost depending on size and specifications |

| Maintenance Frequency | Minimal routine maintenance required | Regular inspection and repair needed | Frequent anti-corrosion maintenance necessary |

| Expected Lifespan | 30+ years with proper maintenance | 20-30 years with significant repair over time | 15-25 years depending on corrosion protection |

| Expansion Costs | Low incremental cost for additional capacity | Very high cost requiring new construction | High cost requiring custom fabrication |

Beyond direct cost considerations, modular water storage tanks contribute significantly to operational efficiency in industrial settings. The ability to implement storage solutions with minimal disruption to existing operations represents a substantial advantage over traditional construction methods that may require extended downtime or operational adjustments.

Proper installation is critical to realizing the full benefits of modular water storage systems. While these systems offer simplified installation compared to traditional alternatives, following established procedures ensures optimal performance, longevity, and reliability. This comprehensive guide outlines the key considerations and steps for successful implementation.

The foundation upon which a modular tank system is installed plays a crucial role in its long-term performance and structural integrity. Unlike traditional tanks that often require specialized concrete foundations, modular systems can typically be installed on simpler, more cost-effective bases while still meeting all structural requirements.

Selecting the appropriate foundation type depends on several factors including soil conditions, water table levels, local climate, and intended use of the stored water. Understanding the available options and their respective advantages enables informed decision-making during the planning phase.

Compacted granular bases represent the most common foundation for modular tanks, offering excellent load distribution and drainage characteristics. Concrete slabs provide enhanced stability for permanent installations but involve higher initial costs. Geotextile-reinforced bases offer an intermediate solution that combines the benefits of both approaches while accommodating sites with less-than-ideal soil conditions.

The assembly process for modular water tanks follows a systematic approach that ensures proper integration of all components while maintaining design specifications. Adhering to established assembly protocols is essential for achieving the intended performance and reliability of the complete system.

While specific assembly details vary between different modular tank systems, most follow a similar general sequence that prioritizes structural integrity and watertight security. The following outline describes the typical assembly process:

Financial considerations often play a decisive role in selecting water storage solutions. While initial purchase price receives significant attention, a comprehensive cost analysis must account for numerous factors throughout the system's lifecycle. This detailed comparison examines the true economic implications of choosing between modular and traditional water storage options.

The upfront costs associated with water storage systems extend beyond simple equipment purchase to include site preparation, installation labor, necessary ancillary equipment, and regulatory compliance expenses. Understanding how these costs differ between modular and traditional approaches provides valuable insight for budget planning.

Traditional storage tanks typically involve significant custom fabrication costs, specialized installation equipment, and extended construction timelines that contribute to higher initial investment. Modular systems benefit from standardized manufacturing processes, simplified installation procedures, and reduced site preparation requirements that collectively lower upfront expenses.

Transportation costs represent another significant differentiator between these approaches. Traditional large-volume tanks often require specialized transportation arrangements and may encounter logistical challenges accessing certain sites. Modular components, by contrast, can be transported using standard methods and assembled on-site regardless of access limitations.

| Cost Component | Modular Tanks | Traditional Tanks |

|---|---|---|

| Manufacturing Cost | Lower due to standardized component production | Higher due to custom fabrication requirements |

| Site Preparation | Simplified foundation requirements reduce costs | Extensive site work often required |

| Installation Labor | Reduced skilled labor requirements | Specialized tradespeople often necessary |

| Transportation | Standard shipping methods typically sufficient | May require specialized equipment and permits |

| Timeline Impact | Faster installation reduces indirect costs | Extended construction period increases costs |

The economic advantages of modular water storage systems become increasingly apparent when evaluating long-term ownership costs. Factors such as maintenance requirements, repair expenses, operational efficiency, and system longevity collectively determine the true financial impact of storage solution selection.

While modular water storage tanks are designed for minimal maintenance compared to traditional alternatives, establishing a proper maintenance regimen remains essential for ensuring long-term performance and reliability. This comprehensive overview details the maintenance considerations specific to modular tank systems, highlighting both routine procedures and strategic inspection protocols.

A proactive approach to maintenance focuses on identifying potential issues before they develop into significant problems, thereby maximizing system lifespan and preventing operational disruptions. Modular tanks lend themselves particularly well to preventative maintenance due to their accessible design and standardized components.

Establishing a regular inspection schedule represents the foundation of effective preventative maintenance. The frequency and thoroughness of these inspections should reflect the specific application, environmental conditions, and criticality of the water storage function. The following inspection framework provides a structured approach to maintaining modular tank systems:

Despite best preventative practices, circumstances may arise requiring corrective action to address specific issues. The modular nature of these storage systems simplifies many repair processes that would be challenging or cost-prohibitive with traditional tank designs.

Understanding how to address typical maintenance requirements ensures prompt and effective resolution of issues while minimizing system downtime. The following scenarios represent commonly encountered maintenance situations and recommended approaches for addressing them:

Seal degradation represents one of the most frequent maintenance concerns in modular tank systems. Unlike traditional tanks where seal repair can be complex and costly, modular systems allow for targeted replacement of specific sealing components without extensive disassembly. Similarly, panel damage typically requires replacement of only the affected modules rather than comprehensive repair of the entire structure.

As water management challenges continue to evolve in complexity and scale, the limitations of traditional storage solutions become increasingly apparent. Modular water storage tanks represent not merely an incremental improvement but a fundamental shift in how we approach water containment across residential, commercial, industrial, and agricultural applications. Their inherent flexibility, economic advantages, and performance characteristics position them as the logical successor to conventional storage methods.

The comprehensive benefits explored throughout this discussion – from benefits of modular water tanks for rainwater harvesting to their role as cost-effective industrial water storage solutions – demonstrate why these systems are transforming water management practices worldwide. The practical guidance provided in the installation guide for modular water tank systems underscores the accessibility of this technology, while the detailed comparing modular vs traditional water tank costs reveals compelling financial advantages. Finally, understanding the straightforward maintenance requirements for modular water tanks completes the picture of a storage solution designed for long-term reliability and performance.

As environmental pressures intensify and water security concerns grow, the adoption of advanced storage technologies like modular tanks will undoubtedly accelerate. Their ability to provide scalable, efficient, and adaptable water storage solutions makes them uniquely suited to address the complex water management challenges of the 21st century and beyond.