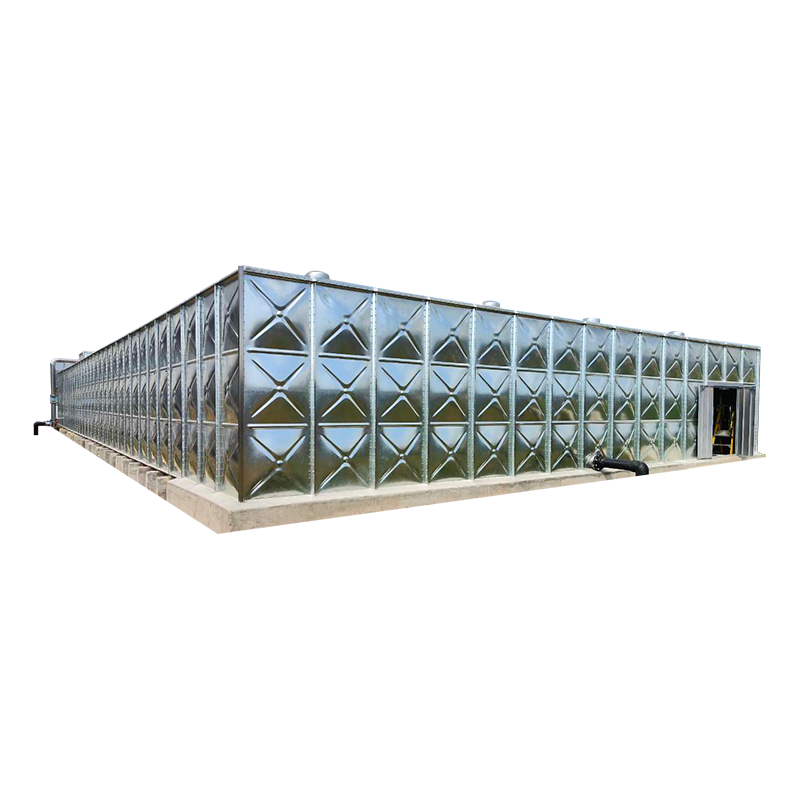

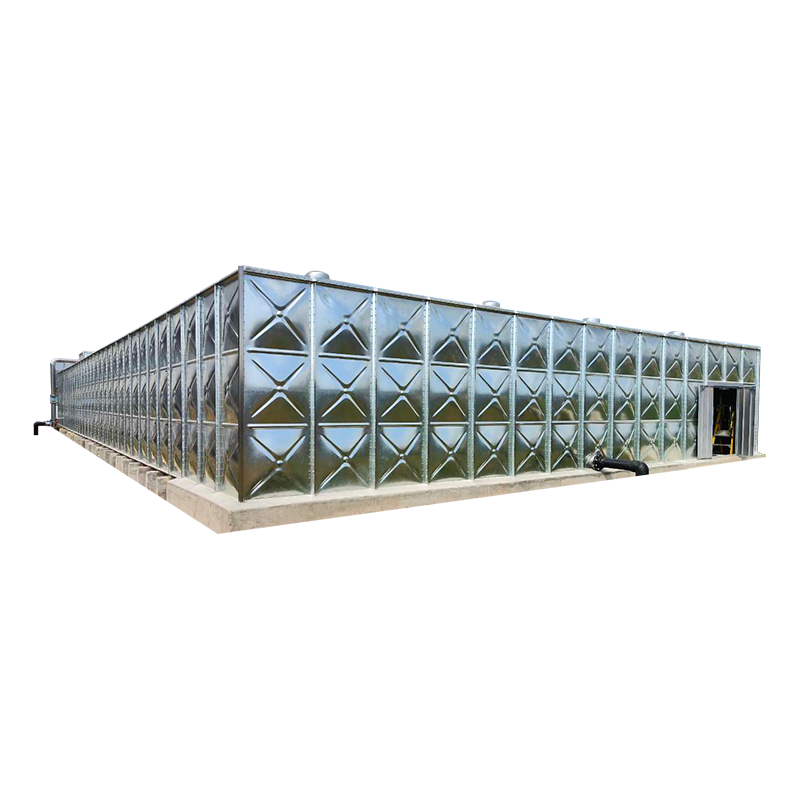

Understanding the hot dipped galvanized water tank

Definition & manufacturing process

- A hot dipped galvanized water tank is a steel-panel-based storage tank whose steel components are immersed in molten zinc to form a metallurgical bond, providing a protective coating.

- The zinc layer acts both as a physical barrier and as a sacrificial anode, so even if scratched, corrosion of the steel substrate is delayed.

Material characteristics & corrosion protection mechanism

- The steel panels are hot-dip galvanised to meet standards such as ASTM A123 (for bolted tanks) which ensures coating thickness and adhesion.

- The zinc-iron alloy layer formed provides long-lasting anti-corrosion performance, even under humid or outdoor conditions.

Comparison with other materials

- Compared to stainless steel tanks: Hot-dipped galvanized tanks typically have lower initial cost, while still offering strong corrosion resistance.

- Compared to painted or coated tanks: The zinc galvanising offers full coverage and better durability than simple field coatings, reducing maintenance.

| Material Type |

Initial Cost |

Corrosion Resistance |

Maintenance Needs |

| Hot-dipped galvanized steel |

Medium |

High |

Low |

| Stainless steel |

High |

Very High |

Very Low |

| Painted/coated steel |

Low |

Medium |

High |

Key Applications for Specialized Long-Tail Needs

hot dipped galvanized fire water storage tank in fire-fighting systems

- Fire protection systems demand highly reliable water storage that can rapidly supply large volumes in emergency. Hot-dipped galvanized tanks are well-suited due to their structural strength and corrosion resistance.

- They are often used above ground or in modular format to meet fire-flow regulation requirements.

Modular installation: modular hot dipped galvanized panel water tank installation

- Modular panel tanks allow flexibility in size, shape and site installation, making them ideal for projects with space constraints or phased expansion.

- Bolted assembly means less on-site welding, shorter installation time and easier future disassembly or relocation.

Secondary water supply: hot dipped galvanized steel water tank for secondary water supply

- Secondary water supply (e.g., for non-potable or building fire systems) benefits from durable water storage tanks that maintain water quality and structural integrity over time.

- A hot-dipped galvanized steel tank is particularly useful in smart water supply systems managed via IoT and big data, providing reliable infrastructure for continuous operation.

Major Benefits & Competitive Advantages

Durability, corrosion resistance, service life

- The hot-dip galvanised zinc coating provides long-term protection, often resulting in service lives of 20–50+ years depending on environment.

- Low maintenance needs: Unlike painted tanks, the galvanised layer does not require frequent re-coating.

Cost-effectiveness vs. other solutions: advantages of hot dipped galvanized water tank for fire-fighting systems

- While stainless steel may offer marginally higher resistance in extreme chemical conditions, the cost difference is significant—making hot-dipped galvanized tanks more cost efficient for many fire-fighting and industrial water storage applications. :contentReference[oaicite:10]{index=10}

- Installation speed and modularity further reduce labor and downtime costs.

Suitability in harsh environments: how to maintain a hot dipped galvanized water tank in coastal environment

- In coastal or high-humidity environments, corrosion risk is elevated. The zinc layer acts sacrificially, protecting the steel substrate even under salt-laden air.

- Recommended maintenance includes periodic inspection of seams/bolts, verifying no breach of zinc layer, and gentle cleaning to avoid damage to the protective coating.

Selection, Installation & Maintenance Best Practices

Key selection criteria (capacity, environment, water quality)

- Determine required volume based on consumption, fire-flow or backup needs.

- Assess environment: outdoors vs indoors, exposure to salt air, chemical vapours etc.

- Check water quality: potable vs fire-water vs irrigation—this may affect panel thickness, lining requirement, gasket selection.

Installation steps & modular assembly advantages

- Prepare foundation: level concrete base or U-channel steel base as required.

- Assemble bottom panels, then side panels, seal joints (rubber-sealant between panels) and bolt together.

- Finish roof panels, install inlet/outlet pipes, overflow, access ladder/manhole. Conduct water-fill test to check for leakage. {index=14}

Maintenance tips & long-term care

- Perform periodic visual inspections of panel joints, bolts, seals and external coating condition.

- Ensure good drainage and ventilation to avoid moisture accumulation around base or between tank and foundation.

- For coastal installations, rinse external surfaces occasionally to remove salt deposits and avoid accelerated zinc corrosion.

- Maintain records of water-level cycles, any repairs, and ensure maintenance schedule is followed for reliable service within the smart water management system context.

Company profile & technical strength

Founded in Jiangsu, the company is a national high-tech enterprise integrating design, R&D, production, sales, installation and service. With a registered capital of 70.18 million yuan and headquarters in coastal Yancheng, Jiangsu, covering 32,600 m² and more than 300 employees, the company has since 2016 focused on secondary water supply technology under the “LeShui Smart Water Affairs” brand.

Product and service advantages

- Strong industry-academia-research cooperation with national institutes and provincial-level R&D platform; dozens of patents and IP rights.

- Products such as SW water tank, integrated box pump station without floating pumps, etc, have been rated provincial-level high-tech products and passed new product/new technology appraisals.

- Participation in standards development (e.g., “Selection and Installation of Prefabricated Integrated Box Pump Fire Water Supply Pump Station”, CECS623-2019 etc) demonstrates technical authority.

- Company is deeply involved in intelligent fire-fighting systems based on IoT, big data, cloud computing and mobile Internet — enabling fully monitored, 24-hour smart water supply equipment solutions.

Customer value & trust

The company’s core business covers smart water system IoT, smart water management platforms, design/maintenance of smart water systems—targeting safe, energy-saving, efficient operations. Since establishment in 2006, the company serves government, hospitals, education and other sectors. It holds ISO9001, ISO14000 and OHSAS certifications, and its fire-fighting products passed the 3C compulsory certification; it is rated as “AAA-level” credit unit in Jiangsu Province.

By choosing this company, you leverage a partner that not only supplies high-quality tanks like the hot dipped galvanized water tank, but also integrates them into full-stack smart water supply solutions—ensuring you receive both product and system service, which means peace of mind, security and satisfaction.

Conclusion & Call to Action

Summary

In summary, selecting the right hot dipped galvanized water tank is crucial for reliable water storage—whether for fire-fighting, secondary water supply or smart water system integration. Understanding the manufacturing process, material benefits, modular installation, environment-specific maintenance and cost-effectiveness gives you a clear path to making a well-informed decision.

Next steps

- Define your project’s water volume, purpose (fire, potable, irrigation, secondary water supply) and site conditions.

- Consult with a qualified supplier—such as the company above—regarding panel size, coating thickness, capacity and integration with your smart water supply system.

- Plan for installation and long-term maintenance within your broader smart water infrastructure strategy.