In the evolving landscape of fire safety, the traditional methods, while effective, often come with the inherent cost of significant water damage to property and crucial assets. Enter the Water Mist System, a revolutionary technology that has fundamentally changed the paradigm of fire suppression. Unlike conventional sprinklers that deluge an area, this system atomizes water into a fine mist, dramatically increasing the water's surface area. This allows for rapid cooling, oxygen displacement, and radiation blocking, all contributing to an efficient and minimal-damage extinguishing process. This article delves into the mechanism, applications, and financial considerations of adopting this cutting-edge technology, ensuring you have the detailed, professional insights needed to make an informed decision for superior safety and asset protection.

The Breakthrough Technology: Understanding the Water Mist System

Water Mist Fire Extinguishing Mechanism - How it Works

The operational brilliance of a Water Mist System lies in the physics of ultra-fine water droplets. When water is discharged at high or low pressure through specialized nozzles, it breaks down into droplets typically less than 1,000 microns in diameter, with some advanced systems achieving droplets as small as 10 microns. This profound increase in surface area compared to traditional fire hoses or sprinklers is the key to its effectiveness. The process is a multi-faceted attack on the fire triangle: it cools the flame and hot gases through rapid vaporization, which absorbs a massive amount of heat (latent heat of vaporization); the resulting steam expands rapidly, locally displacing oxygen around the fire, a process often referred to as 'inerting'; and finally, the mist droplets themselves act as a radiant heat barrier, protecting surrounding surfaces from ignition. This three-pronged mechanism allows the system to extinguish fires with significantly less water, thereby minimizing post-fire damage. The proficiency of the system ensures a swift and contained response, which is crucial in environments where both rapid suppression and minimal collateral damage are paramount.

- Enhanced Cooling: The rapid vaporization of small water droplets absorbs heat 50 to 100 times faster than the same volume of water from a standard sprinkler head.

- Local Inerting: The conversion of water to steam expands the volume by approximately 1,700 times, effectively diluting the oxygen concentration in the immediate vicinity of the fire, starving it of fuel.

- Radiation Shielding: The dense cloud of fine mist acts as an opaque barrier, blocking radiant heat transfer and preventing the fire from spreading to adjacent materials.

- Minimal Cleanup: The use of dramatically less water means reduced water run-off, structural damage, and corrosion, leading to shorter business interruption times and lower recovery costs.

Water Mist vs Traditional Fire Suppression Methods

While traditional sprinkler systems have been the backbone of fire protection for decades, a professional evaluation often highlights their limitations, especially concerning water damage and application-specific performance. Conventional sprinklers rely on massive volumes of coarse water droplets to primarily cool the fire and wet down surrounding fuel. This high volume, while extinguishing the fire, often results in catastrophic water damage to electronics, documents, artwork, and historic structures. In contrast, the Water Mist System achieves superior fire suppression with a fraction of the water, making it a compelling alternative. For instance, in areas with sensitive equipment or limited water supply, the efficiency of water mist becomes a critical factor. Furthermore, the localized nature of the mist means that once activated, the impact is confined, unlike deluge systems. When considering a system, the choice often boils down to a balance between initial cost, potential asset loss, and long-term operational impact, and in many high-value scenarios, water mist provides a clear and superior return on safety investment.

A comparison of the two primary systems reveals the core differences:

| Feature | Water Mist System | Traditional Sprinkler System |

| Water Droplet Size | Ultra-fine (typically < 1000 microns) | Coarse (typically > 1000 microns) |

| Primary Extinguishing Action | Cooling, Inerting (Oxygen Displacement), Radiation Blocking | Cooling and Wetting |

| Water Consumption | Low (Up to 90% less) | High (Significant water demand) |

| Collateral Damage | Minimal/Negligible | High (Due to excessive water discharge) |

Applications & Key Considerations

Protecting Cultural Heritage: Water Mist System for Historic Buildings

Historic and heritage structures present a unique set of challenges for fire protection engineers. These buildings are often irreplaceable, contain invaluable artifacts, and may have architectural features that are highly sensitive to water damage. Furthermore, installing large-diameter piping required for conventional sprinklers can be architecturally intrusive and may compromise the building's historical integrity. This is where the Water Mist System for Historic Buildings truly shines. The system's use of small-diameter tubing (often stainless steel) is far less intrusive and easier to conceal within existing structures, preserving the aesthetic and historical fabric. Most importantly, the minimal water usage ensures that priceless frescoes, wooden structures, and archival materials are protected from the catastrophic secondary damage associated with flooding. Regulatory bodies and conservators increasingly recommend or mandate water mist technology for libraries, museums, archives, and heritage sites due to its effective suppression capabilities coupled with its gentle impact on sensitive materials. The technology provides a necessary balance, delivering life safety and property protection without sacrificing the cultural value of the asset being protected.

- Aesthetic Preservation: Small, often flexible, piping can be discreetly installed, respecting the original architecture and avoiding structural modifications.

- Reduced Risk to Assets: Minimizes the risk of irreparable damage to irreplaceable documents, artwork, and historical finishes caused by high volumes of water.

- Code Compliance: Increasingly accepted by authorities for protecting sensitive occupancies where traditional sprinklers are deemed too damaging.

- Quick Deployment: The rapid fire knockdown capability is crucial in preventing a small fire in a heritage structure from becoming a total loss event.

Residential Safety: Water Mist vs Sprinklers Residential

For homeowners and developers, the decision between a traditional sprinkler system and a water mist solution for domestic properties often centers on space, aesthetics, and the very real concern of accidental water discharge and associated damage. The debate of Water Mist vs Sprinklers Residential is increasingly relevant as building codes evolve. While traditional residential sprinklers are highly effective at saving lives, the volume of water they release can ruin expensive furnishings, flooring, and electronics. The compact nature of a water mist system's components, including its smaller pipework and water storage requirements, makes it a more attractive option for modern, high-density, or luxury residential spaces where concealment and aesthetics are crucial design considerations. Furthermore, the risk of a false alarm leading to massive water discharge is significantly lower and less damaging with a water mist system. This is a critical factor for high-end properties and condominiums where the cost of water damage can easily exceed the cost of the system itself. Choosing water mist is a premium choice that prioritizes both life safety and the preservation of the home's contents and structure.

Key differences in a residential context:

| Factor | Water Mist Residential | Traditional Sprinklers Residential |

| Piping Size | Small, less intrusive (often 10-25mm) | Large, often requires more concealment work |

| System Response | Rapid cooling and suppression with minimal water | High-volume soaking |

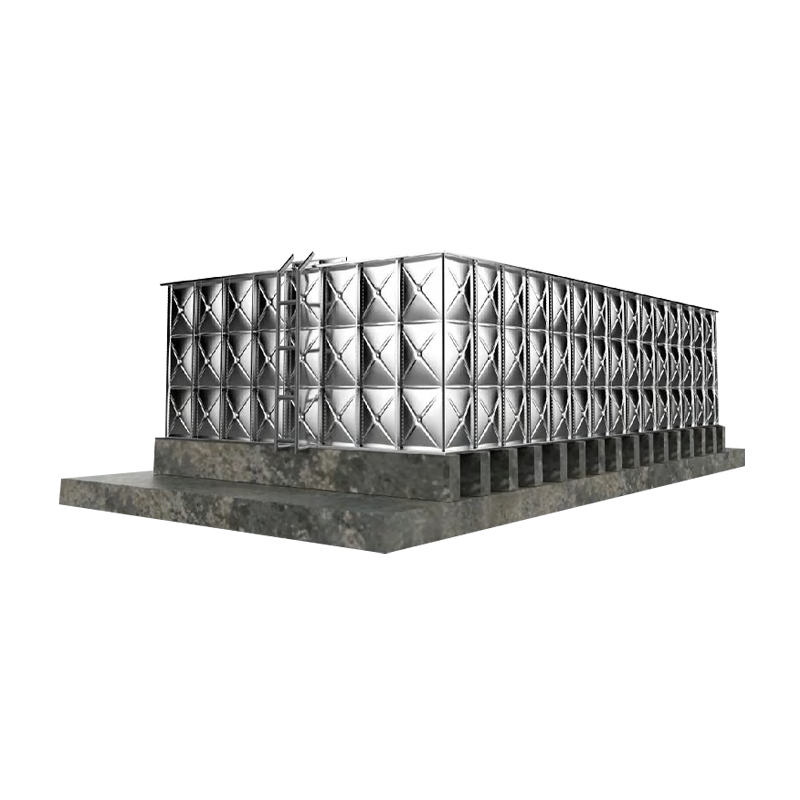

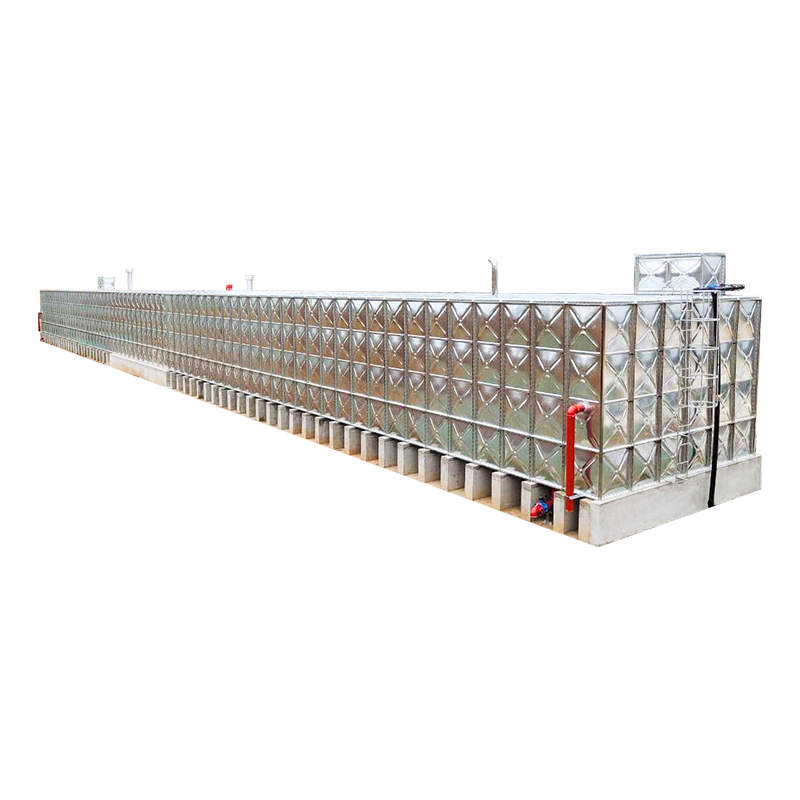

| Water Storage Needed | Significantly less, smaller tanks/pumps required | Large reserve tank often mandated |

| Aesthetics/Installation | Easier to conceal, less architectural impact | Can be challenging to integrate seamlessly |

Technical Specifications and Investment

Exploring Low-Pressure Water Mist System Advantages

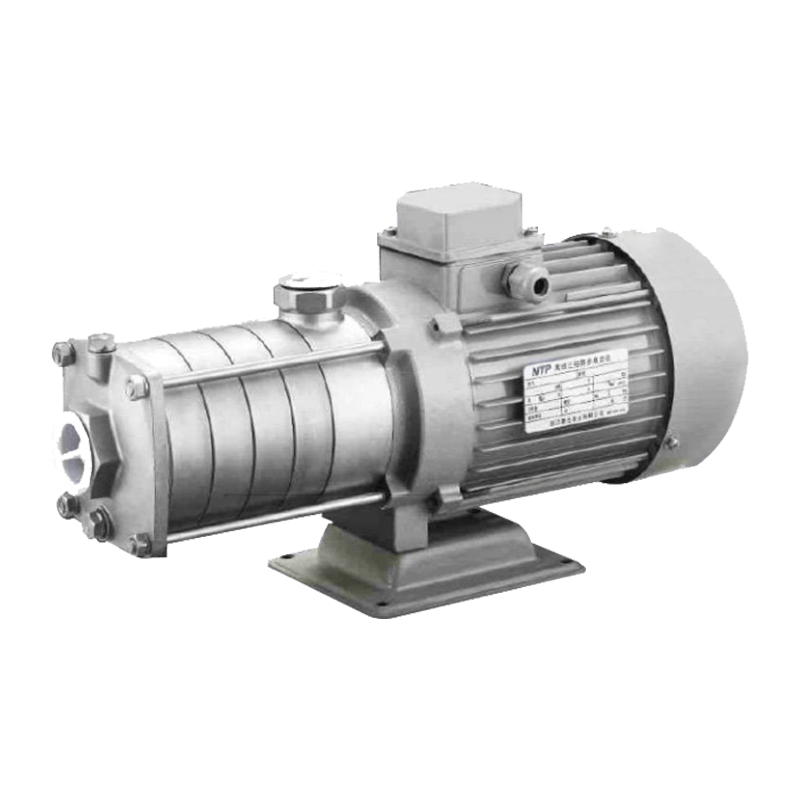

While high-pressure systems are often cited for their superior droplet size, the Low-Pressure Water Mist System Advantages make it an increasingly popular and practical choice for many commercial and industrial applications. Operating typically below 12.5 bar, low-pressure systems are inherently simpler to design, install, and maintain. They utilize more robust, often off-the-shelf components, which contributes to a lower overall ownership cost and easier access to spare parts. Crucially, the lower operating pressure eliminates the need for specialized, highly trained maintenance personnel and ultra-high-pressure fittings, making them more accessible for a wider range of facilities. While the droplet size may be slightly larger than their high-pressure counterparts, the flow rate and nozzle design are optimized to achieve effective fire suppression for many common hazard classifications, including light and ordinary hazards. For large volume spaces or applications where system simplicity and reliability are prioritized over the absolute finest mist, the low-pressure solution often offers the best balance of performance, cost-effectiveness, and ease of operation. This is particularly true in areas like office buildings, hospitals, and light manufacturing.

- Simplified Maintenance: Lower pressure means less wear and tear on pumps and components, simplifying service requirements.

- Reduced Installation Cost: Standard piping materials and connections can often be used, reducing the initial complexity and expense of installation.

- Flexibility in Water Supply: Can often be directly connected to the building's existing water supply, provided pressure and flow requirements are met.

- Reliable Operation: Fewer complex components and seals generally translate to a highly reliable and robust system with fewer potential failure points.

Evaluating High-Pressure Water Mist Fire Suppression System Cost and ROI

The upfront High-Pressure Water Mist Fire Suppression System Cost is undeniably higher than conventional sprinkler systems, and often higher than low-pressure mist alternatives. This is primarily due to the need for specialized, often bespoke, high-pressure pumps, stainless steel or equivalent high-grade piping and fittings capable of handling pressures up to and exceeding 100 bar, and precision-engineered nozzles to achieve the required ultra-fine mist. However, when evaluating the total cost of ownership (TCO) and return on investment (ROI), a more nuanced picture emerges. The higher initial investment is often offset by several long-term savings: reduced water bills and required water storage capacity; significant reduction in post-fire cleanup and downtime; and lower insurance premiums due to the minimal damage risk. For high-value assets such as data centers, industrial turbines, or luxury cruise ships, the potential loss from a fire, coupled with the secondary damage from traditional water deluge, can be catastrophic. In these critical environments, the rapid suppression and minimal collateral damage provided by a high-pressure system offer an unparalleled ROI, effectively making the higher initial cost an investment in long-term operational resilience and asset preservation. A professional cost-benefit analysis will invariably justify the expense for environments where seconds and minimal damage count.

Key financial and operational considerations:

| Metric | Initial Investment | Long-Term Savings/ROI Factor |

| Hardware Cost | High (Specialized pumps, nozzles, piping) | Lower maintenance/component failure rate than low-pressure in some applications |

| Water Supply Infrastructure | Reduced (Smaller pipes, less tank volume) | Lower utility costs and less impact on existing building services |

| Damage Mitigation | --- | Massive reduction in post-fire structural and content damage, shortening downtime |

| Insurance Premium | --- | Potential reduction in property and business interruption insurance rates |

FAQ

What is the minimum pressure required for an effective Water Mist System?

The term "minimum pressure" is relative, as the optimal pressure is entirely dependent on the system design and the hazard being protected. Water mist systems are broadly categorized into low-pressure (typically below 12.5 bar), intermediate-pressure (between 12.5 and 35 bar), and high-pressure (above 35 bar, often exceeding 100 bar). The key performance indicator is the ability of the system to generate a specific distribution of water droplets small enough to achieve the combined cooling, inerting, and radiation blocking effects. For example, systems designed to meet the requirements of the Water Mist vs Sprinklers Residential standard often operate at lower pressures for simplicity, while systems protecting complex machinery like industrial turbines or deep-fat fryers may require high pressures to generate the ultra-fine mist necessary for penetrating and suppressing multi-dimensional fires. Always consult the system's listing and approval standards (such as NFPA 750 or IMO guidelines) to determine the exact pressure requirements needed for guaranteed fire suppression efficacy for your specific application.

Can a Water Mist System replace an existing Halon or clean agent system?

Yes, in many critical applications, the Water Mist System is now the preferred, environmentally-friendly replacement for legacy Halon and other chemical clean agent systems. Halon, while extremely effective, has been phased out due to its high ozone depletion potential (ODP). While clean agents like FK-5-1-12 or Inergen are excellent for certain high-value assets (e.g., data centers), they primarily extinguish fire by smothering or chemical reaction, and their cost per cubic meter protected can be extremely high. Water mist offers a superior combination: it is non-toxic, uses only pure water, is infinitely replenishable, and the residual damage is minimal. Furthermore, the Water Mist Fire Extinguishing Mechanism involving simultaneous cooling and oxygen displacement is highly effective across a wide range of fire classes. For specific hazards, a direct comparison of the tested performance (e.g., those meeting the VdS or FM approval for a given hazard) must be made. However, given the focus on non-damaging, sustainable solutions, water mist is increasingly chosen, especially in environments like the Water Mist System for Historic Buildings or marine applications.

What factors most heavily influence the High-Pressure Water Mist Fire Suppression System Cost?

The cost of a high-pressure system is primarily driven by the material specifications and the engineering complexity required to manage the elevated operating pressures. The most influential factors are: 1. Pumping Unit: The heart of the system, this requires specialized, high-tolerance pumps and motors, which account for a significant portion of the cost. 2. Piping Material: High-pressure systems mandate the use of stainless steel, copper-nickel, or other specialized alloys, as standard carbon steel piping is inadequate. This material is far more expensive than the black steel used for traditional sprinklers. 3. Nozzle Design: The nozzles are precision-engineered to create the optimal droplet size distribution under high pressure, making them intricate and costly to manufacture. 4. System Size and Zoning: The total number of nozzles and the extent of the protected area directly scales the material and labor costs. While the initial High-Pressure Water Mist Fire Suppression System Cost is high, it is essential to factor in the long-term ROI derived from the minimal damage and reduced insurance premiums, which are significant benefits not offered by lower-cost conventional systems.