Dec 05, 2025

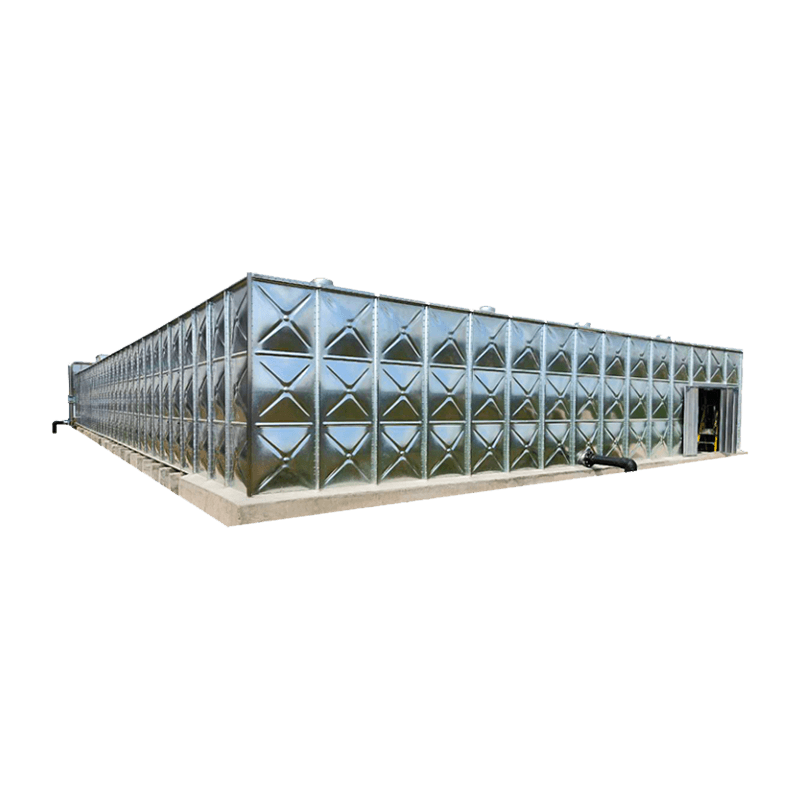

The modern Sectional Water Tank has become one of the most adaptable forms of water storage across industrial, commercial, and residential environments. Due to its modular design, it allows users to assemble tanks of different capacities regardless of site limitations. This flexibility makes it ideal in scenarios that require both high-volume water storage and structural efficiency. In recent years, the demand for modular sectional water tank design has increased, particularly in areas where rapid infrastructure development or space constraints require efficient solutions. The structure of sectional tanks also facilitates easy inspection, improved sanitation control, and long-term durability. By incorporating segmented panels, it becomes easier to maintain or replace individual components without dismantling the entire tank, significantly reducing downtime and repair costs.

| Feature | Sectional Tank | Traditional Tank |

| Installation Flexibility | High | Low |

| Component Replacement | Easy | Difficult |

| Space Adaptability | Excellent | Limited |

The rise of modular sectional water tank design solutions is largely driven by the need for customizable water storage systems that can adapt to evolving infrastructure demands. Unlike one-piece tanks, sectional systems can be transported through narrow construction zones, rooftops, basements, and high-rise buildings without requiring specialized lifting equipment. They are also suitable for emergency applications, such as disaster relief or temporary water stations. Because each section can be assembled on-site, designers and engineers can configure the exact capacity required, ensuring optimal use of space. In addition, segmentation enhances structural stability and supports both cold and hot water applications, making the tank suitable for diverse environments worldwide.

| Parameter | Modular Tank | Fixed Tank |

| Transportability | Very Easy | Difficult |

| Capacity Adjustment | Flexible | Fixed |

| Structural Versatility | High | Low |

The popularity of sectional water storage tanks for buildings stems from their reliability and suitability for multi-story, commercial, and residential projects. In commercial complexes, these tanks serve as essential components in fire protection systems, water backup solutions, and day-to-day supply storage. Residential buildings benefit from their leak-resistant design and long lifespan. The flexibility of Sectional Water Tank structures makes them easy to install in basements, rooftops, and confined mechanical rooms. With cities aiming for more sustainable water usage, these tanks help integrate rainwater harvesting systems and recycled water distribution with ease.

| Use Case | Benefit |

| Commercial Buildings | Stable large-volume storage |

| Residential Towers | Reliable daily water supply |

| Public Institutions | Long-term durability |

A wide range of large facilities prefer using GRP sectional panel water tank system solutions due to their superior hygienic properties and corrosion resistance. These systems are often seen in factories, data centers, industrial processing plants, and educational campuses where consistent water quality is essential. GRP panels are lightweight, making them ideal for rooftop installations without adding excessive structural load. When properly maintained, a GRP sectional tank delivers decades of high performance with minimal degradation, helping facility managers control operational costs. Their ability to withstand extreme temperature variations also makes them suitable for regions with harsh climates.

| Material | GRP Tank | Steel Tank |

| Corrosion Resistance | Excellent | Moderate |

| Weight | Light | Heavy |

| Thermal Stability | High | Medium |

When implementing large storage systems, many engineers rely on a steel sectional water tank installation guide to ensure safety, durability, and compliance with structural requirements. Steel sectional tanks are especially suited for industrial and agricultural environments due to their strength and resistance to mechanical stress. The installation process typically begins with site preparation, involving foundation leveling and reinforcement. Next, panels are transported individually and assembled using bolted connections, allowing precise alignment and long-lasting structural integrity. Because components can be replaced independently, maintenance is significantly more efficient compared to traditional welded tanks.

| Step | Description |

| 1 | Prepare foundation and support beams |

| 2 | Assemble steel panels in sequence |

| 3 | Apply sealing and reinforcement |

As global water systems become more advanced, the benefits of sectional water tank construction have gained significant interest among architects, contractors, and water management professionals. The segmented panel structure offers unmatched flexibility, making it possible to expand or modify capacity according to changing water needs. Additionally, the assembly method ensures tanks can be transported economically and erected quickly, shortening project timelines. From an operational standpoint, sectional tank designs make maintenance more predictable and cost-effective, enabling individual sections to be isolated for cleaning or repair without disrupting the overall supply system.

| Benefit | Sectional Tank | Concrete Tank |

| Installation Time | Short | Long |

| Capacity Expansion | Easy | Impossible |

| Maintenance | Low | High |

As infrastructure requirements evolve, comparing the performance of sectional tanks with traditional water tanks reveals clear advantages. Sectional tanks—whether steel, GRP, or composite—are engineered to handle variable loads, temperature fluctuations, and long-term exposure to moisture. Traditional tanks, especially those built from concrete or single-piece plastic, often suffer from cracking, leakage, or UV degradation over time. With the improved structural engineering behind Sectional Water Tank systems, users enjoy better reliability and lower maintenance costs over the service life of the installation.

| Property | Sectional Tank | Traditional Tank |

| Durability | High | Medium |

| Weather Resistance | Excellent | Moderate |

| Maintenance Frequency | Low | High |

Cost efficiency is a significant factor in determining the ideal water storage system. Sectional tanks offer clear financial advantages due to their low installation costs, reduced labor requirements, and long operational lifespan. Because damaged panels can be individually replaced, operators avoid expensive full-system repairs. Furthermore, tanks using GRP sectional panel water tank system components have nearly zero corrosion-related maintenance costs. Traditional tanks often incur higher costs for structural reinforcement, coating repairs, and leakage prevention.

| Cost Category | Sectional Tank | Traditional Tank |

| Installation | Low | High |

| Maintenance | Low | High |

| Repair | Sectional Panel Replacement | Full Structure Repair |

Most Sectional Water Tank systems have a lifespan of 20–40 years depending on material type, installation conditions, and maintenance practices. GRP and steel options generally offer the longest operational stability.

Yes. The flexible configuration of a modular sectional water tank design makes it ideal for small buildings with limited installation space or difficult site access.

Absolutely. A GRP sectional panel water tank system provides excellent sanitary performance, making it widely used for drinking water storage worldwide.

Following a proper steel sectional water tank installation guide ensures safe and efficient assembly. Most installations are faster and cheaper than fixed concrete tank installations.

The benefits of sectional water tank construction include faster installation, easier maintenance, flexible capacity expansion, and superior long-term performance.