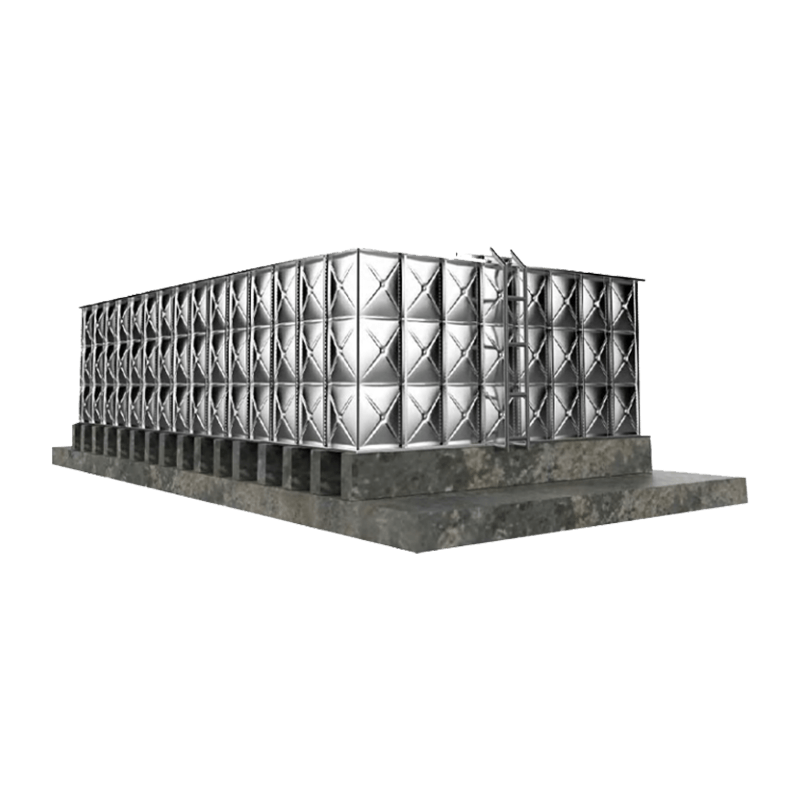

Hygienic Mandate and Material Purity

This category specifically emphasizes tanks constructed exclusively for potable (domestic) water storage, where the material and construction must meet the highest global standards for food and water contact safety. The tanks are always fabricated from 304 or 316 Stainless Steel, selected for its non-leaching and non-reactive properties, coupled with smooth, crevice-free interiors to prevent microbial growth.

The tank utilizes food-grade internal components, including certified EPDM or silicone gaskets and seals. These tanks ensure that the stored water remains safe and free from secondary contamination and chemical leaching.

Specification Table: Food Grade SS Tank

| Material Grade | 304 or 316 Stainless Steel (Food Grade Certification) |

| Internal Finish | Smooth, Polished or 2B Finish (R-Value Minimized) |

| Sealing Components | NSF/WRAS Certified Food-Grade EPDM/Silicone |

| Internal Weld Standard | Continuous TIG Welds (for Welded Tanks) or Bolted Construction |

| Light Protection | Opaque or Light-Blocking Design for Algae Prevention |

| Access | Hygienic Manhole Cover with Pressure-Release Vent |

| Drainage | Sloped Bottom for Full Drain and Cleaning Capability |

| Certifications | FDA/NSF 61 (Component Level), Local Health Authority Approvals |

Application Fields

- Dedicated storage for drinking water in schools, hospitals, and high-density residential towers.

- Holding tanks for the Food and Beverage industry (bottling plants, breweries, dairies).

- Storage for pharmaceutical compounding water and purified water systems.

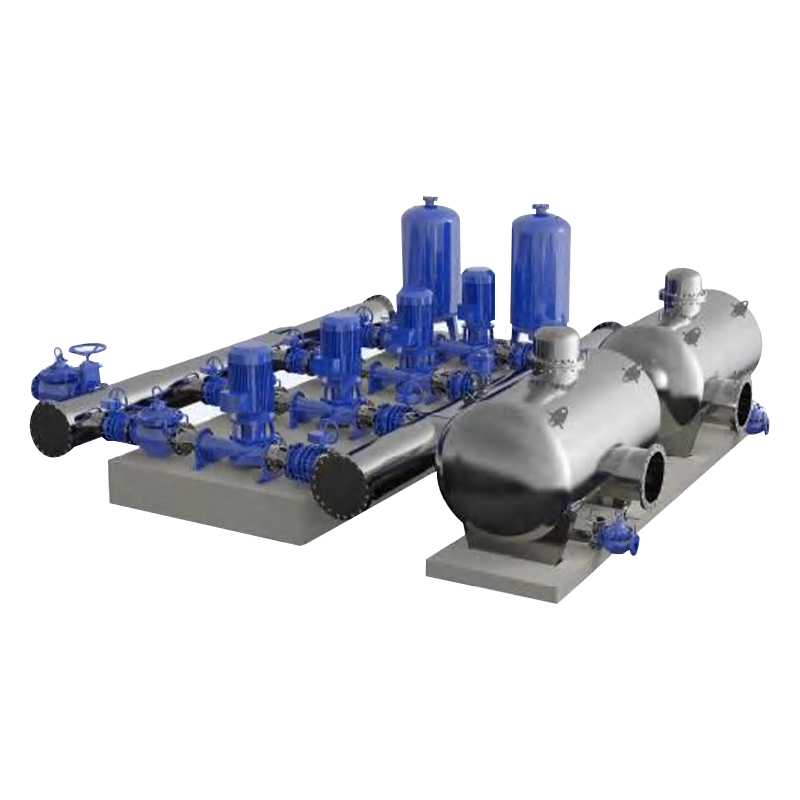

- Supply reservoirs for the Variable Frequency Water Supply Equipment With Water Quality Improvement Function.

- Any application where human consumption is the primary end-use of the stored water.

Engineering and Custom Fabrication

Production is performed in dedicated, clean fabrication bays to minimize the risk of contamination from non-SS materials (e.g., carbon steel dust).

Customization Scope: Integration of specialized hygienic features such as Clean-In-Place (CIP) spray balls and nozzles, sampling ports, and custom internal partitioning for maintaining separate water quality zones.

We adhere to the highest manufacturing protocols to ensure the longevity of the stainless steel's passivity layer.