Innovative Corrugation for Enhanced Stiffness

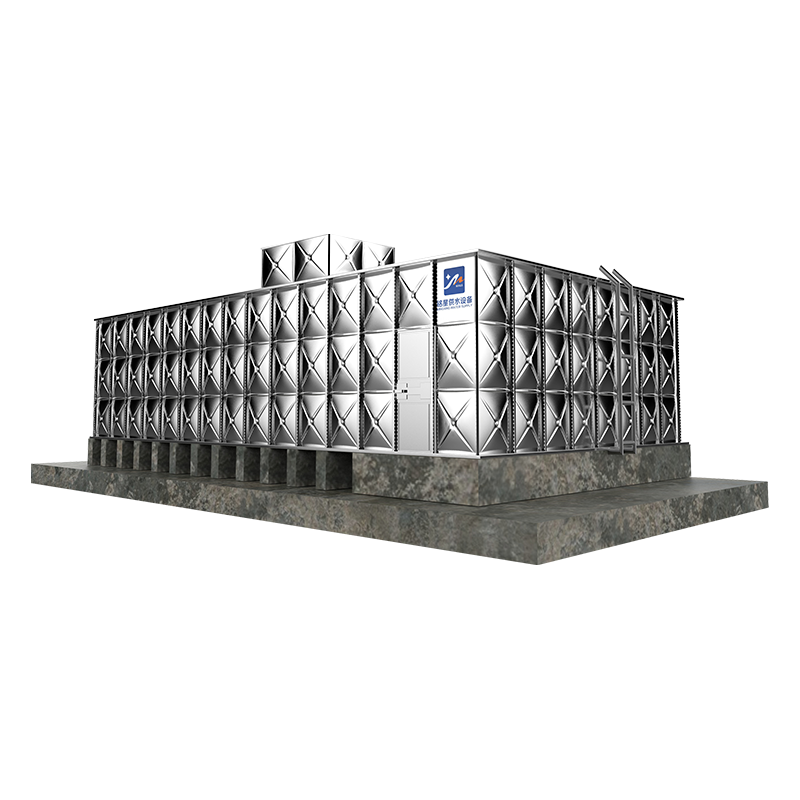

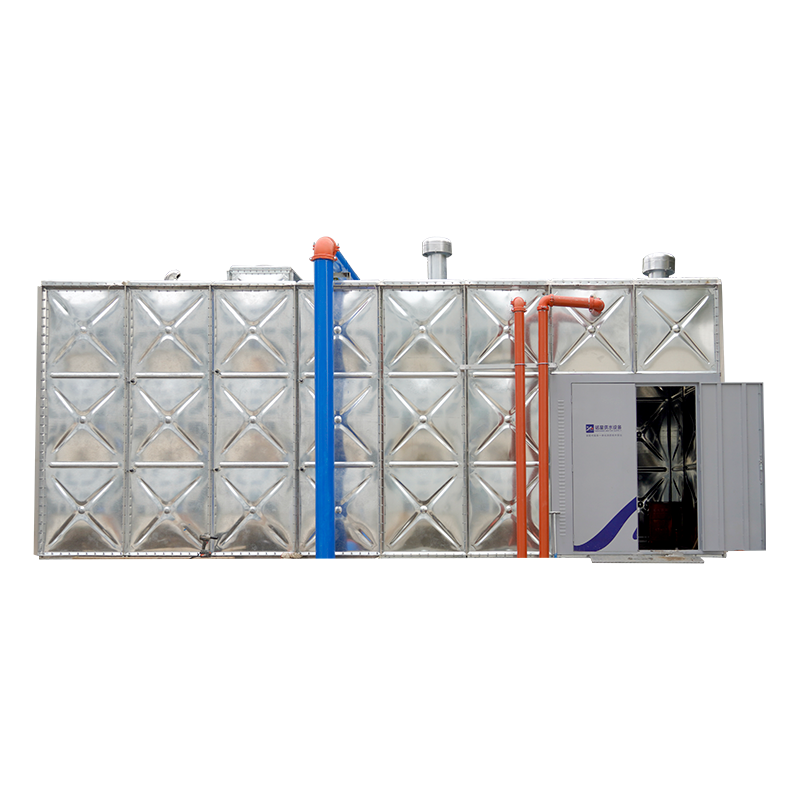

The Stainless Steel Corrugated Water Tank is a storage solution that utilizes thin-gauge stainless steel panels that have been mechanically shaped into a deep, wave-like corrugated profile. This corrugation drastically increases the panel's rigidity and strength-to-weight ratio compared to flat panels of the same thickness.

The enhanced stiffness allows for reduced material thickness, which lowers the overall weight and material cost while maintaining structural integrity. These tanks are typically cylindrical or rectangular and are either welded or bolted, depending on the scale and application, favored for their light weight and superior strength.

Specification Table: SS Corrugated Tank

| Structural Feature | Deep Wave Corrugation Profile |

| Material | Thin-Gauge 304 or 316 Stainless Steel |

| Stiffness | Significantly Higher than Flat Panels |

| Weight | Lower Overall Structural Weight |

| Construction | Welded (Small-Medium) or Bolted Sectional (Large) |

| Aesthetic | Unique, Wavy Appearance |

| Cost Efficiency | Reduced Material Cost per Unit Volume |

| Application | Potable Water, Process Water |

Application Fields

- Rooftop water storage where minimal structural load and corrosion resistance are needed.

- Rural and agricultural water storage (cylindrical models) where ease of transport and assembly is required.

- Industrial process water storage where chemical compatibility of SS is required, but weight is a factor.

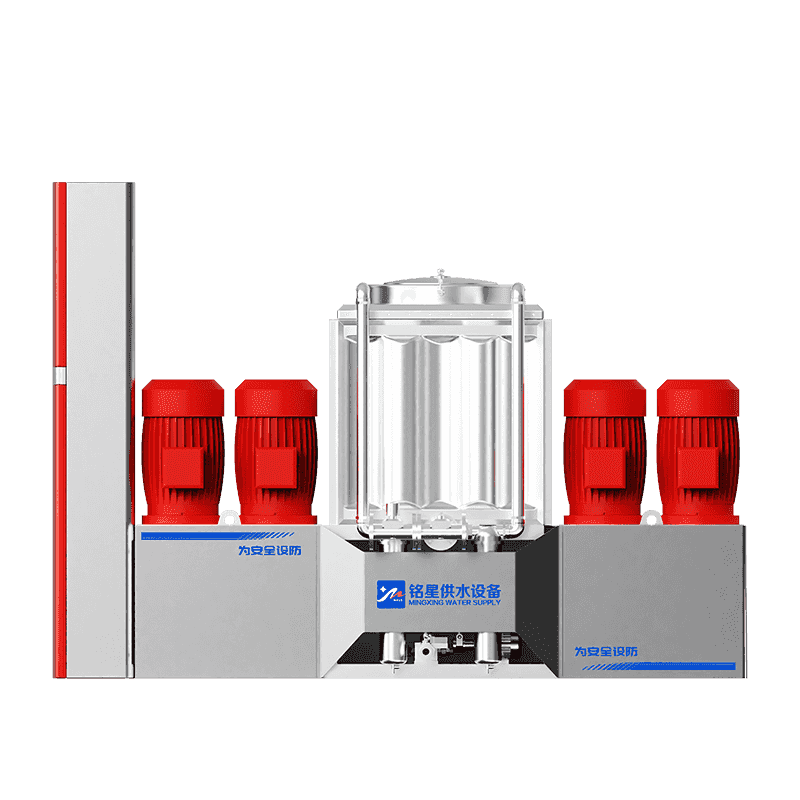

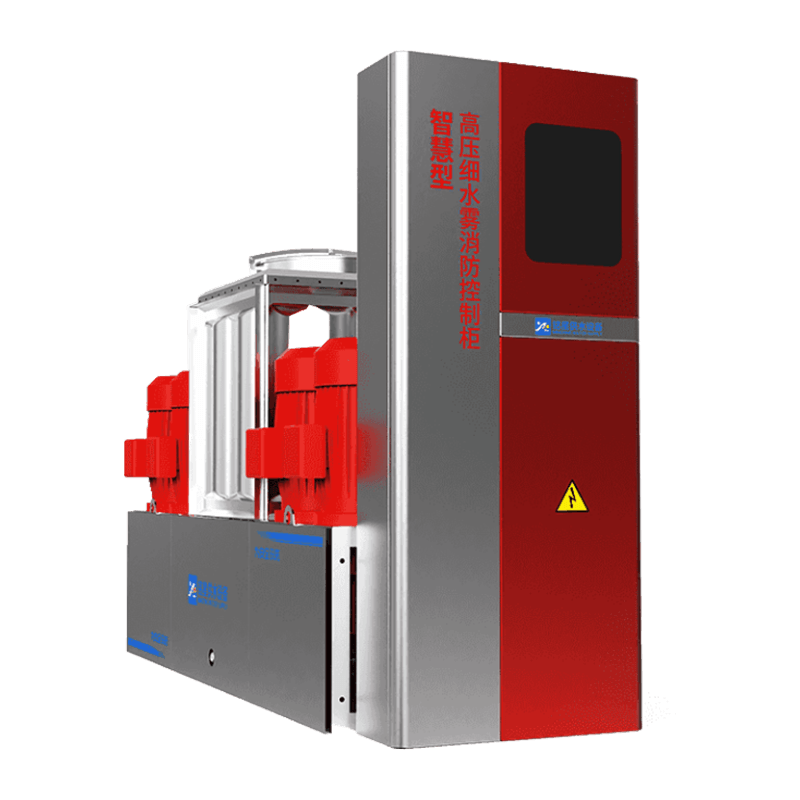

- Integrated into the Box-Type Pumping Station as a compact, lightweight reserve.

- Water collection and non-potable storage systems.

Engineering and Custom Fabrication

Panels are formed using highly accurate roll-forming or pressing machinery to ensure consistent corrugation and structural alignment for assembly.

Customization Scope: Specific pitch and depth of corrugation based on tank volume, integration of anti-slosh baffles within the corrugated structure, and custom placement of nozzles on the corrugated surface via specialized welding processes.

Structural calculations verify that the corrugated design provides adequate resistance to wind loading and hydrostatic pressure.