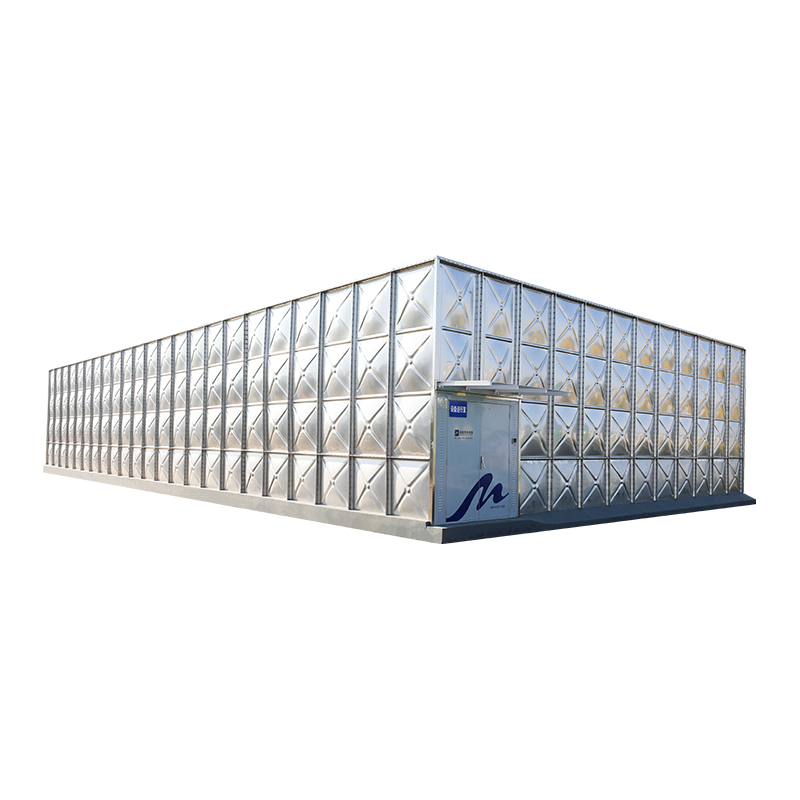

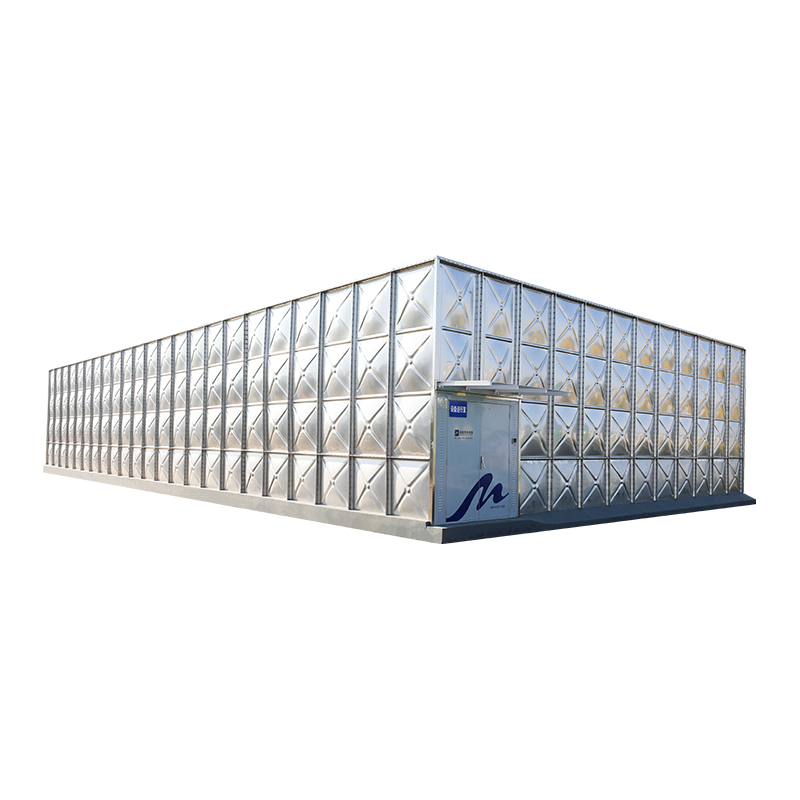

Definition of Sectional Cold Water Storage Tanks: Modular, panel-based water holding systems that can be assembled onsite to meet specific capacity requirements.

- Importance: Ensures reliable cold water storage for industrial, commercial, and fire safety applications.

- Advantages: Flexible design, scalable capacity, easy transport, and installation compared to conventional one-piece tanks.

- Jiangsu Mingxing Water Supply Equipment Co., Ltd provides customized solutions for Sectional Cold Water Storage Tanks with IoT-enabled smart water management.

Understanding Modular Design

Concept of Modular Design

- Assembled from individual panels with bolts and seals.

- Allows for custom tank sizes tailored to project specifications.

- Facilitates installation in locations with limited access, including rooftops or basements.

- Compatible with secondary water supply systems and fire safety installations.

Advantages Compared to Traditional Tanks

| Feature |

Modular Sectional Tank |

Traditional One-Piece Tank |

| Installation Ease |

High – assembled onsite from panels |

Low – requires large access and crane lifting |

| Customization |

Extensive – panels can create any dimension |

Limited – factory-made sizes only |

| Transportation |

Easy – panels shipped separately |

Challenging – bulky and heavy |

| Maintenance |

Accessible – panels allow internal inspection |

Limited access – harder to clean and repair |

Applications and Use Cases

Industrial Applications

- Process water storage in manufacturing plants.

- Backup water supply for cooling systems, boilers, and production lines.

- Supports secondary water supply systems for large-scale facilities.

- Custom engineered modular sectional cold water storage tanks for industrial use provide optimal space utilization.

Fire Safety and Building Systems

- Reliable water reserve for fire suppression systems, sprinklers, and hydrants.

- Compliance with local building codes and fire safety regulations.

- Integration with smart water monitoring for immediate leak detection and water level control.

- Comparative advantage: sectional tanks allow modular expansion versus rigid pre-fabricated tanks.

Municipal and Commercial Use

- High-rise residential and commercial buildings: modular tanks can fit in rooftops or mechanical rooms.

- Hotels, hospitals, and schools benefit from scalable capacity and redundancy.

- Water conservation and reuse: tanks can integrate with rainwater harvesting and greywater systems.

Comparison: Usage Scenarios

| Use Case |

Sectional Tanks |

Other Storage Tanks |

| Industrial Water Reserve |

Excellent – customized dimensions and capacity |

Good – factory size may not fit requirements |

| Fire Safety |

Reliable – compliant with fire codes, expandable |

Moderate – fixed size, limited flexibility |

| High-rise Buildings |

Adaptable – fits restricted spaces |

Challenging – may require crane access |

| Maintenance & Inspection |

Accessible – panels allow internal checks |

Limited – difficult to reach corners |

Installation Insights

Step-by-Step Overview

- Site preparation: Level foundation, check structural load capacity.

- Panel assembly: Align panels, secure with bolts, apply sealing material.

- Connection fittings: Inlet, outlet, overflow, and overflow valves.

- Leak testing: Hydrostatic testing to ensure integrity.

- Commissioning: Integration with building water network and IoT monitoring systems.

Installation Considerations

- Accessibility: Modular panels can pass through tight spaces, unlike one-piece tanks.

- Foundation: Must withstand water weight; structural analysis is recommended.

- Environmental factors: Temperature, corrosion, UV exposure, and seismic conditions.

- Regulatory compliance: Follow local plumbing codes and fire safety standards.

Customization & Engineering Solutions

Tailored Engineering Options

- Custom dimensions and storage capacity according to project requirements.

- Special coatings for corrosion resistance and chemical compatibility.

- Specific inlet/outlet configurations for integration with pumps, sprinklers, and pipelines.

- Integration with smart water systems: IoT sensors for monitoring water level, temperature, and quality.

Advantages of Custom Solutions

- Optimized for industrial or commercial needs.

- Facilitates phased installation and future expansion.

- Reduces operational downtime with pre-engineered modular components.

- Improves overall water safety and compliance management.

Maintenance Best Practices

Routine Maintenance Tasks

- Regular visual inspection for leaks, corrosion, and structural integrity.

- Check seals and bolts for wear or loosening.

- Cleaning: Remove sediment and biofilm to ensure water quality.

- Monitor water quality: Conduct microbiological and chemical tests periodically.

- Documentation: Maintain records of inspections and maintenance actions.

Long-Term Service Planning

- Scheduled component replacement for panels, gaskets, and valves.

- Periodic structural assessment and retrofitting if needed.

- Integration with IoT monitoring: Alerts for abnormal water level, leakage, or temperature.

- Training of maintenance staff on safety and emergency procedures.

Benefits of Sectional Cold Water Storage Tanks

Efficiency and Scalability

- Allows incremental expansion of water storage capacity.

- Reduces downtime during upgrades or repairs.

- Optimizes space utilization in buildings and industrial facilities.

Cost and Resource Optimization

- Lower transportation costs due to modular shipping.

- Reduces installation labor and equipment requirements.

- Long service life minimizes replacement and operational costs.

Safety and Compliance

- Reliable emergency water supply for fire safety and industrial operations.

- Easy monitoring and inspection ensure adherence to regulatory standards.

- Customizable to meet local building and safety codes.

- Jiangsu Mingxing Water Supply Equipment Co., Ltd is China Custom Sectional Water Storage Tanks Manufacturers and Wholesale Sectional Cold Water Storage Tanks Suppliers.

- The company offers full-stack “smart water supply” solutions based on IoT and big data; headquarters in Yancheng, Jiangsu, covering 32,600 m² with 300+ staff.

- Established LeShui Smart Water Affairs brand in 2016; focuses on innovation in secondary water supply technology.

- Branches and direct sales offices in Shanghai, Anhui, Sichuan, and other regions provide safe living and fire-fighting water supply equipment.

Frequently Asked Questions (FAQ)

1. What makes Sectional Cold Water Storage Tanks different from traditional tanks?

- Modular assembly allows flexibility in size and onsite installation in locations with limited access.

2. How does a modular sectional cold water storage tanks for industrial use system benefit facilities?

- Provides scalable water storage with minimal installation disruption; integrates with secondary water supply systems.

3. What should I know from a sectional cold water storage tanks installation guide?

- Site preparation, panel assembly, sealing, leak testing, and IoT monitoring integration are key steps for proper installation.

4. Why are benefits of sectional cold water storage tanks in fire safety important?

- Ensures emergency water availability, compliance with fire codes, and modular expansion to meet changing needs.

5. What are sectional cold water storage tanks maintenance best practices?

- Routine inspections, cleaning, seal and bolt checks, water quality monitoring, and component replacement planning.

6. Can sectional tanks be customized for unique project requirements?

- Yes, with custom dimensions, inlet/outlet arrangements, coatings, and integration with smart water monitoring systems.

7. What are the long-term advantages of modular sectional tanks?

- Lower operational costs, scalable capacity, easy maintenance, and compliance with safety regulations.