Jan 14, 2026

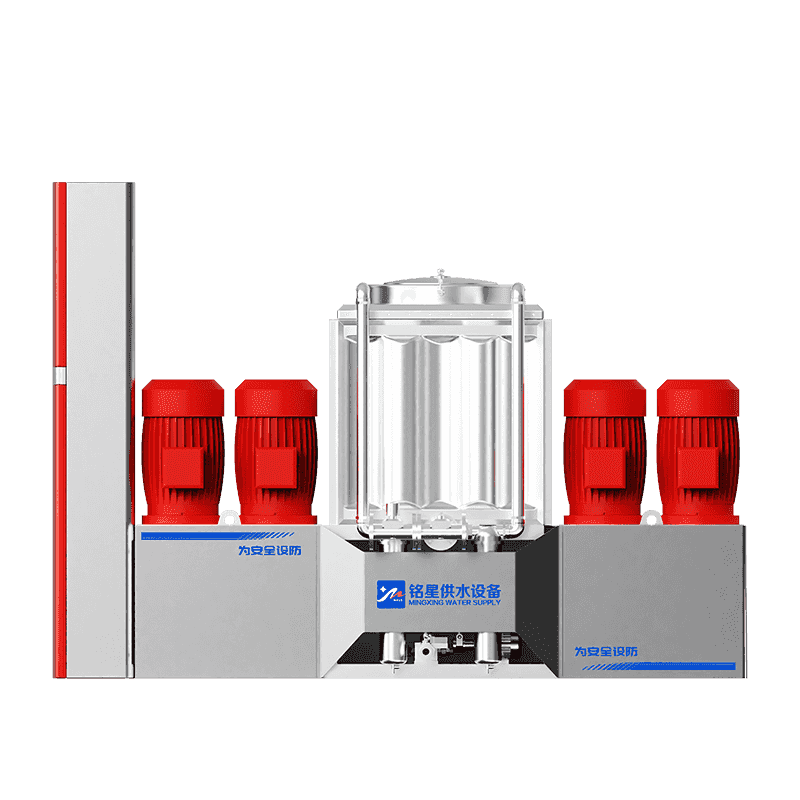

Industrial operators and procurement engineers face a complex decision process when selecting a reliable Water Pump System tailored for industrial environments. From municipal water distribution to manufacturing plant processes, the right system must balance performance, lifecycle cost, and compliance with evolving technical standards. This guide integrates contemporary industry insights to help professionals make well‑informed selection decisions.

The global market for industrial pumping solutions continues to expand, driven by infrastructure modernization, factory automation, wastewater management, and sustainability imperatives. According to the latest industry analysis, over 92.3 million industrial pump units were deployed globally as of 2024, with a rising share of smart, energy‑efficient systems facilitating predictive operations and remote monitoring. Source: Market Growth Reports – Industrial Water Pumps Market Size, Share & Growth (2024‑2025)

Source: Industrial Water Pumps Market Size, Share & Growth

An accurate selection process for an industrial pump involves understanding fluid type, duty cycles, integration with smart control platforms, and compliance with applicable technical standards.

Industrial systems differ from residential or agricultural pumps primarily in terms of:

An effective selection process begins with defining duty point, net positive suction head (NPSH) requirements, and fluid properties. Engineers typically model several scenarios under different load conditions before finalizing a design specification.

Industrial facilities increasingly incorporate IoT connectivity into pump systems to support remote monitoring, predictive maintenance, and integration with enterprise asset management. Such systems enhance uptime and reduce lifecycle cost compared to traditional unmonitored installations.

Forecasts indicate accelerating adoption of smart pumps, with an estimated global smart pump market reaching USD 1.6 billion by 2025. Source: Business Research Insights – Smart and Intelligent Pumps Market Trends

Source: Smart and Intelligent Pumps Market Size & Trends

Energy efficiency translates directly into lower operating costs. Systems that comply with modern efficiency standards can reduce electrical consumption by up to 25‑30% compared to older installations. Materials science advancements and variable frequency drives (VFDs) contribute to these gains.

Wastewater applications demand robust design features such as solids handling, corrosion‑resistant materials, and submersible options. Engineers must account for sediment load, chemical corrosion potentials, and fluctuating head conditions. These criteria differ significantly from clean water supply applications.

The integration of analytics platforms can predict impending bearing failures, cavitation, or seal wear, allowing maintenance to be scheduled before failure. This is especially important in industrial operations where unplanned downtime is costly.

The table below contrasts common industrial pump categories to assist specification decisions:

| Criteria | Centrifugal Pumps | Positive Displacement Pumps | Smart Integrated Pumps |

| Best Use Case | High flow water distribution | High pressure, viscous fluids | Remote monitoring & predictive control |

| Efficiency | Good at design duty point | Variable by fluid type | Optimized via analytics |

| Monitoring | Basic instruments | Basic instruments | Full IoT & sensor suite |

| Maintenance Strategy | Reactive to scheduled | Reactive to scheduled | Predictive enabled |

Accurate load calculation includes total dynamic head (TDH), required flow rate, and pump curve intersections to ensure operating point efficiency.

Modern industrial systems should interface with facility SCADA or centralized asset management platforms, enabling condition‑based triggers and remote diagnostics.

Choosing the right Water Pump System for industrial settings requires a structured approach that considers fluid properties, duty demands, system controls, maintenance philosophy, and future scalability. Leveraging smart integration, energy efficiency, and robust design frameworks ensures reliable operation and optimized lifecycle costs.

Key criteria include required flow rate, head pressure, fluid characteristics, energy efficiency targets, and compatibility with control systems.

IoT integration enhances remote monitoring, predictive diagnostics, and real‑time performance optimization.

Centrifugal pumps excel at high flow clean water, while positive displacement is suited for viscous or high‑pressure fluids.

By anticipating failures and scheduling repairs, predictive maintenance reduces unplanned downtime and extends component life.

Yes, both ISO and ANSI compliance for pump efficiency and safety influence system design specifications in industrial contracts.