Jan 08, 2026

As urban density increases globally, fire safety engineers face a recurring challenge: integrating high-capacity water storage into high-rise structures where space is a premium and access routes are restricted. While traditional systems often struggle with logistics, the Modular Fire-Fighting Water Tank has emerged as the definitive engineering solution. This article explores why modularity, combined with high-grade material selection, is reshaping the "smart fire-fighting" landscape for modern vertical infrastructure.

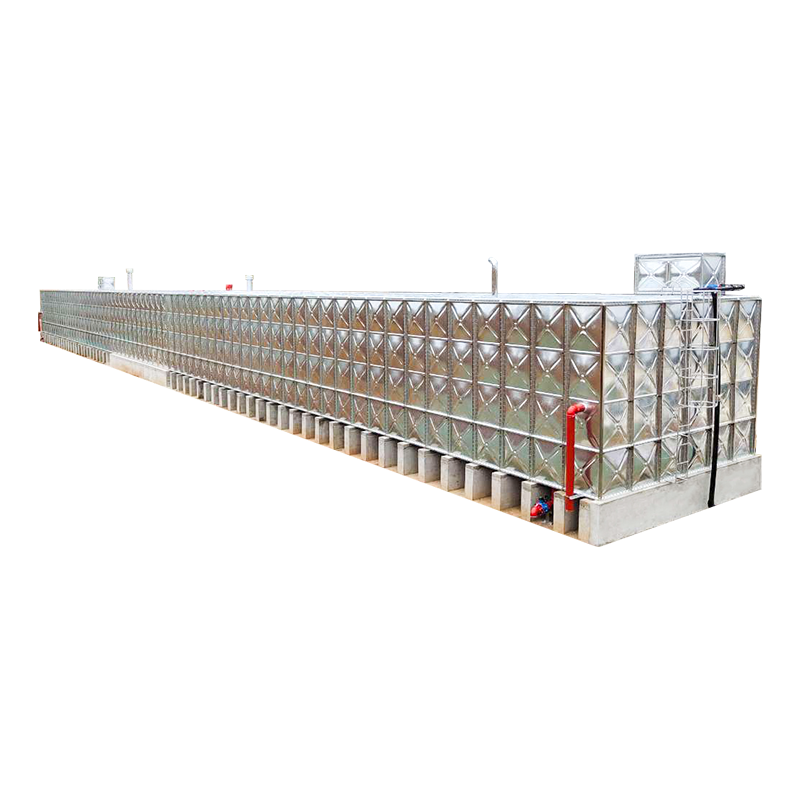

In high-rise construction, retrofitting or installing fire protection systems in basements or rooftop mechanical rooms is often hindered by narrow corridors, elevators, and small doorways. A Modular Fire-Fighting Water Tank is designed for "flat-pack" delivery, where individual panels are transported to the site and bolted together in situ. This eliminates the need for heavy machinery or structural demolition to fit a pre-fabricated unit.

Traditional concrete or large welded tanks require significant staging areas and heavy lifting equipment, which are rarely available in congested urban centers. In contrast, modular systems leverage lightweight, high-strength panels that can be moved by standard freight elevators.

| Feature | Monolithic/Welded Tanks | Modular Fire-Fighting Water Tank |

| Transport Method | Requires oversized vehicle permits and cranes. | Flat-packed panels fit in standard lifts. |

| Installation Site | Needs wide-open access during construction. | Can be installed in confined basements or rooftops. |

| Assembly Speed | Weeks of curing (concrete) or on-site welding. | Rapid bolt-together assembly in days. |

For high-rise fire protection, durability is non-negotiable. A Stainless Steel Water Tank provides superior corrosion resistance and structural integrity compared to plastic or carbon steel alternatives. In the context of "Smart Water Supply" solutions, the material’s longevity ensures that the fire system remains operational for decades without the risk of internal scaling or leak-prone degradation.

According to the latest technical guidelines from the National Fire Protection Association (NFPA), the reliability of water storage materials is critical in seismic zones and high-load urban environments. Recent data suggests that the shift toward prefabricated metallic storage has reduced maintenance-related downtime by nearly 30% in commercial high-rises.

Source: NFPA 22: Standard for Water Tanks for Private Fire Protection

| Metric | Galvanized Steel | Stainless Steel Water Tank |

| Corrosion Resistance | Moderate (requires coating maintenance). | Excellent (naturally oxidation-resistant). |

| Water Purity | Risk of zinc leaching over time. | Food-grade/Hygiene compliant. |

| Structural Weight | Heavy. | High strength-to-weight ratio. |

The engineering depth of a Modular Fire-Fighting Water Tank lies in its flexibility. These systems can be configured in "L" shapes, "U" shapes, or wrap around structural pillars, maximizing every cubic meter of available space. This is particularly vital for custom fire water storage solutions where the floor plan is non-standard.

For large-scale industrial or commercial projects, the stainless steel tank cost for large capacity storage is often offset by the significant savings in labor and site preparation costs. Furthermore, specialized insulated stainless steel water tank variants are available for high-rise buildings in colder climates to prevent freezing in unheated mechanical penthouses.

Modern fire safety is no longer just about hardware; it is about intelligent data. Drawing from the expertise of Jiangsu Mingxing Water Supply Equipment Co., Ltd., high-rise systems now integrate "Smart Water Affairs" platforms. These platforms use Big Data and the Internet of Things to provide a full-stack solution, ensuring that the fire water tank for high-rise buildings is always at peak readiness.

As a national high-tech enterprise with a registered capital of 70.18 million yuan and over 300 employees, our R&D focuses on the "LeShui Smart Water Affairs" brand. We have led the compilation of several industry standards, including CECS623-2019 for prefabricated integrated pump stations. This ensures that every fire tank for restricted space we provide meets the most stringent provincial and national high-tech product appraisals.

| Task | Standard Modular Tank | Smart Integrated Modular Tank |

| Level Monitoring | Manual inspection or simple float valves. | Real-time IoT ultrasonic sensors. |

| Compliance Reporting | Manual logging. | Automated digital audit trails. |

The Modular Fire-Fighting Water Tank is not just a storage vessel; it is a sophisticated component of the modern "Smart City" infrastructure. By selecting a corrosion resistant modular water tank, engineers ensure long-term safety, regulatory compliance, and ease of maintenance in the most challenging high-rise environments.

Yes. Because the tank is composed of individual panels, it can be carried through standard doorways and assembled in confined basement areas where a traditional tank could not fit.

Stainless steel is lighter, easier to clean, and does not suffer from the cracking or porous seepage common in concrete tanks. It also offers a much faster installation timeline.

While the initial material cost may be higher than plastic, the long-term ROI is superior due to zero maintenance needs, 30+ year lifespans, and significantly lower site-work costs.

Absolutely. Modular tanks can be engineered with reinforced internal bracing and thicker base plates to meet specific seismic rating requirements for high-rise zones.

In high-rise buildings where the mechanical room is not climate-controlled and located in cold regions, an insulated tank is recommended to prevent the fire reserve from freezing, ensuring 24/7 readiness.