Jan 27, 2026

In the world of water management, sectional water storage tanks represent a cornerstone technology for ensuring reliable water supply across residential, commercial, industrial, and municipal sectors. Unlike monolithic tanks, these modular systems offer unparalleled flexibility, scalability, and durability. As a national high-tech enterprise specializing in full-stack "smart water supply" solutions, Jiangsu Mingxing Water Supply Equipment Co., Ltd. brings deep expertise to this critical field. This guide delves into everything you need to know about sectional water tanks, exploring their types, advantages, key considerations, and how modern IoT integration is revolutionizing their functionality.

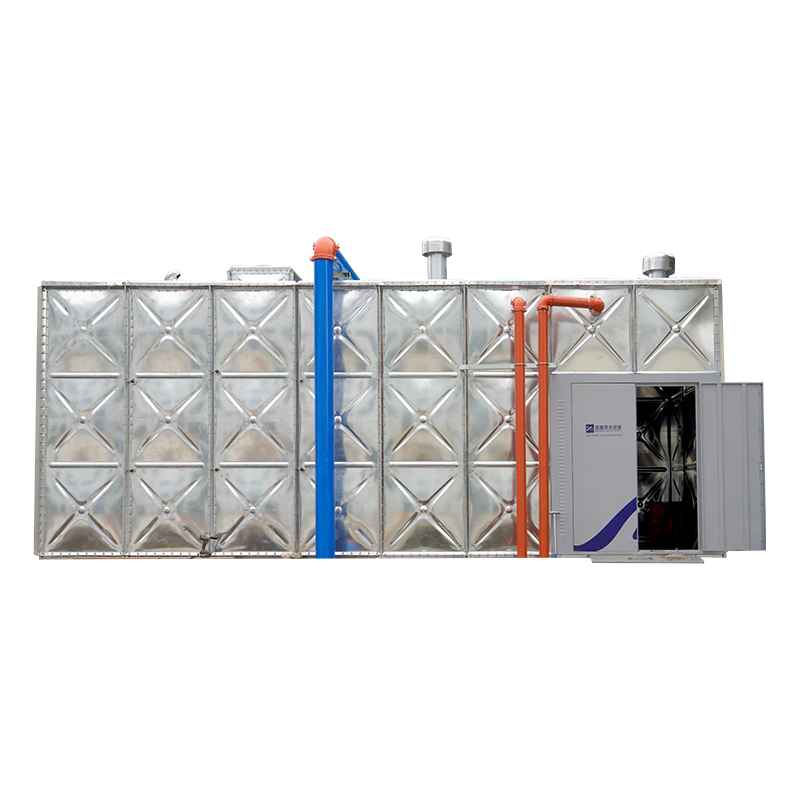

Sectional water storage tanks, also known as panel or modular tanks, are large-capacity storage systems constructed from prefabricated, bolted panels. These panels, typically made from robust materials like galvanized steel, stainless steel, or coated steel, are assembled on-site to create a container of virtually any size or shape. This modularity is their defining characteristic, setting them apart from one-piece tanks.

The popularity of sectional tanks stems from a host of practical and economic benefits that address the limitations of traditional storage methods.

Constructed from corrosion-resistant materials and protected by advanced coatings, these tanks are built to withstand harsh environmental conditions, offering decades of reliable service with minimal maintenance, provided industry standards for design and construction are followed [4].

The versatility of sectional tanks makes them suitable for a wide range of applications, each with specific requirements.

Understanding the differences between tank types is vital for making an informed choice. The key distinctions often lie in material, coating, and structural design, which are standardized to ensure performance and safety [1].

| Type | Core Material | Interior Lining/Coating | Best Suited For |

|---|---|---|---|

| Hot-Dip Galvanized Steel | Steel coated in zinc | Often paired with supplemental epoxy or polyester lining | Fire protection, industrial water, agricultural use |

| Stainless Steel | Grade 304 or 316 stainless steel | Typically self-finish; may have passivation | High-purity potable water, pharmaceutical, food & beverage |

| Bolt-Free Panel Systems | Coated steel or composite | Integrated food-grade polymer coating | Applications where minimizing internal crevices is a priority |

Fire protection systems have non-negotiable reliability standards. The cost of a fire-rated sectional tank is influenced by several factors beyond the tank itself, including compliance with installation standards for fire pumps [2].

Investing in a certified system from an experienced provider like Jiangsu Mingxing Water Supply Equipment Co., Ltd., which leads in intelligent fire-fighting integrated pump station standards, ensures compliance and long-term safety, offering superior value over the tank's lifespan.

Regular maintenance is key to longevity. A typical schedule includes:

This is a fundamental comparison for many projects. The choice impacts budget, timeline, and long-term performance.

| Criteria | Sectional Water Tank | Concrete Tank |

|---|---|---|

| Installation Speed | Fast (days/weeks) | Slow (weeks/months) |

| Initial Cost | Generally lower | Generally higher |

| Flexibility & Relocation | High (modular, movable) | Very Low (permanent structure) |

| Permeability Risk | Zero (with intact lining) | Possible (can crack over time) |

| Foundation Requirements | Less demanding | Extensive and reinforced |

| Long-term Maintenance | Predictable (coatings, bolts) | Unpredictable (crack repair) |

The lining is the critical barrier protecting water quality. For potable water, the lining must be non-toxic, durable, and resistant to bacterial growth, and it must comply with health effects standards for drinking water components [3].

The selection depends on water chemistry, budget, and desired service life. Companies with strong R&D backgrounds, such as Jiangsu Mingxing Water Supply Equipment Co., Ltd., which holds numerous patents and develops provincial-level high-tech products, are adept at recommending and applying the optimal lining solution.

Correct sizing is crucial for efficiency and cost-effectiveness. An undersized tank fails to meet demand, while an oversized one wastes resources. Follow these steps:

The evolution of sectional water storage tanks is intertwined with digital innovation. Moving beyond passive storage, modern tanks are becoming intelligent nodes in a connected water network.

As a pioneer in IoT-based smart water supply, Jiangsu Mingxing Water Supply Equipment Co., Ltd., through its LeShui Smart Water brand, exemplifies this trend. Their solutions leverage big data and cloud computing to turn a sectional tank into a source of operational intelligence, enhancing safety, efficiency, and peace of mind for clients in government, healthcare, and education sectors.

With proper material selection, coating, and adherence to a maintenance schedule for galvanized sectional water tanks, a well-maintained sectional tank can have a service life of 25 years or more, as their design accounts for long-term durability [4]. Stainless steel and glass-fused-to-steel tanks can last even longer.

Yes, but it requires careful engineering. The tank must be designed to withstand external soil and hydrostatic pressures, following specific engineering recommendations for such applications [4]. Special coatings, cathodic protection, and rigorous waterproofing are essential. Above-ground installation is more common and cost-effective.

Absolutely. Their long life, recyclable materials (steel), and role in enabling rainwater harvesting and efficient water management contribute to sustainability. The precision manufacturing also minimizes material waste.

Lead time is generally shorter than for concrete tanks. After design approval, manufacturing of panels takes a few weeks. The major time variable is on-site assembly, which is relatively fast. This speed is a significant advantage when calculating the total project cost of installing a sectional water tank for fire protection or other urgent applications.

Start by choosing the best lining for potable water in a sectional tank that is certified to relevant health effect standards [3]. Implement regular inspection and cleaning schedules. Ensure vents and hatches have insect and vermin screens. For ultimate assurance, integrate IoT-based water quality monitoring to receive instant alerts about any changes in water conditions.

Sectional water storage tanks offer a robust, flexible, and intelligent solution for diverse water storage challenges. From understanding the sectional water tank vs concrete tank pros and cons to how to calculate the size of a sectional water tank needed, informed decision-making is key. By partnering with a technologically advanced provider that combines quality manufacturing with smart IoT integration, you can secure not just a storage vessel, but a reliable, efficient, and future-proof component of your water infrastructure. The commitment to innovation and quality, as demonstrated by enterprises like Jiangsu Mingxing Water Supply Equipment Co., Ltd., ensures that modern water storage meets the highest standards of safety, efficiency, and sustainability.