Structural Design and Equipment Integration

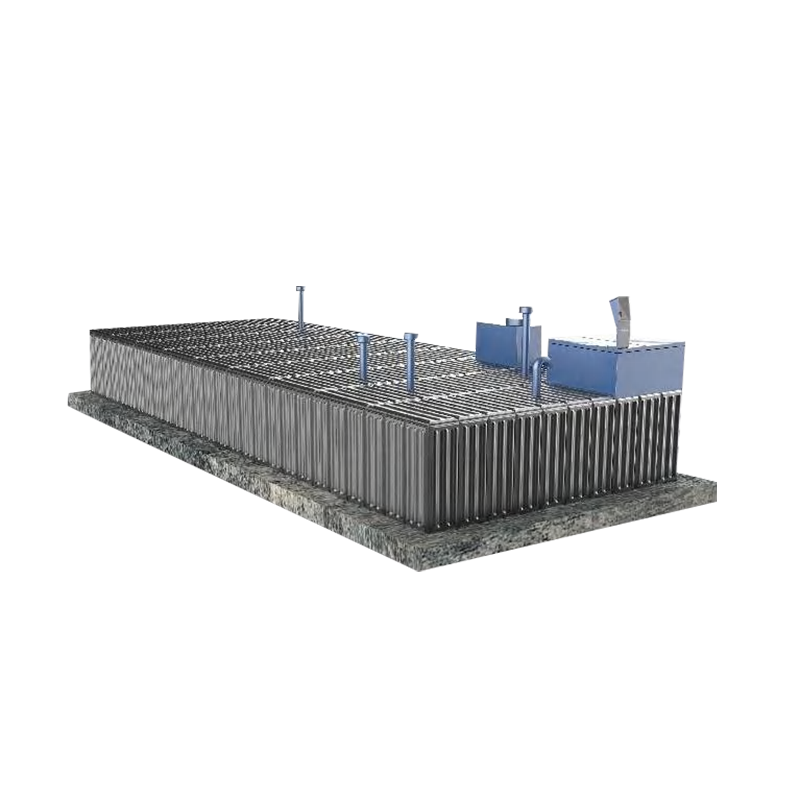

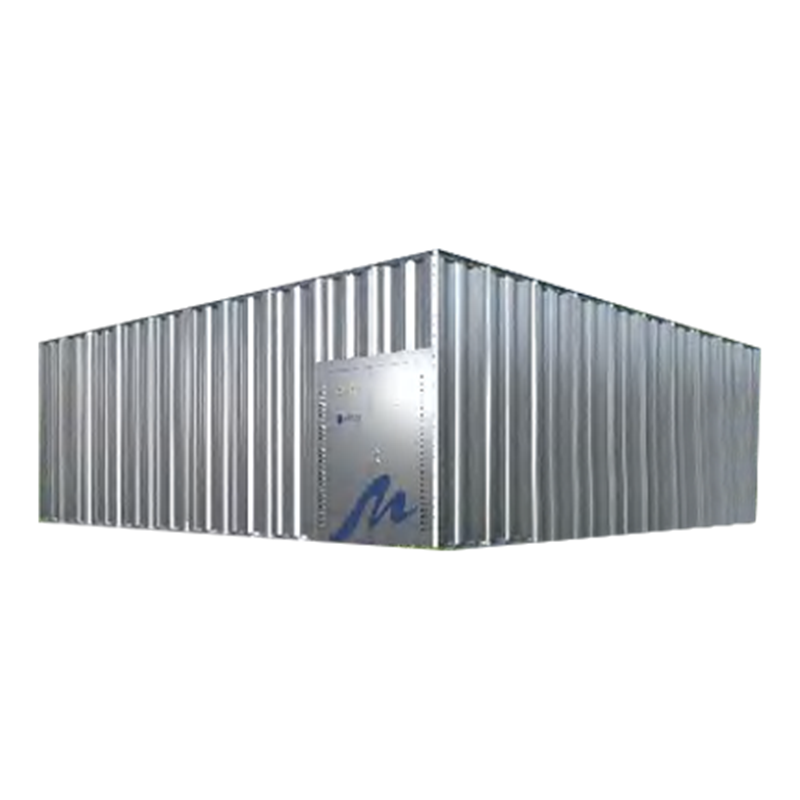

The Arc Rib Pump Station is an integrated, prefabricated pump house that leverages the enhanced structural rigidity of arc-ribbed wall panels. This design, derived from the successful Bidirectional Arc-Ribbed Super Rigid SW Water Tank, provides superior resistance to external forces, soil pressure (for partially buried models), and internal hydrostatic loads.

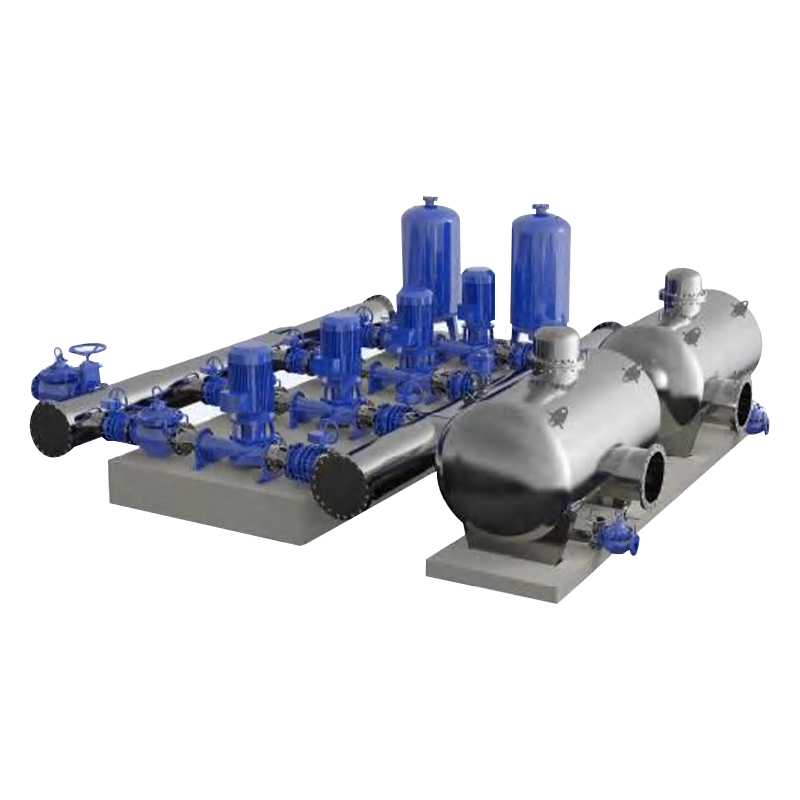

The 'station' integrates the pump equipment (pumps, VFDs, manifolds, controls) within the arc-ribbed structure, creating a single, robust, and often partially or fully submersible package. This structure is designed for swift installation as a complete unit, minimizing complex on-site construction and providing a protected, climate-controlled environment for the equipment.

Specification Table: Arc Rib Pump Station

| Structural Feature | Bidirectional Arc-Ribbed Panel Design |

| Configuration | Above-Ground, Semi-Buried, or Fully Buried Options |

| Pump Type | Variable (Centrifugal, Fire, or Sewage) |

| Material | Hot-Dip Galvanized Steel, Composite Plate (BDF) |

| Environmental Control | Integrated Ventilation and Insulation |

| Footprint | Customizable Modular Dimensions |

| Compliance | CECS623-2019 (Reference for Integrated Stations) |

| Maintenance Access | Watertight Access Hatch with Integrated Ladder |

Application Fields

- Rural or remote water distribution hubs requiring a robust, non-corroding structure.

- Integrated fire and domestic water boosting utilizing the structure as both a tank and a pump room (BDF model).

- Subterranean water systems (Buried Intelligent Integrated Pumping Station) requiring structural strength against soil load.

- Oil and gas facility non-potable water boosting and transfer systems.

- Industrial cooling water pump houses in areas prone to seismic activity or high wind loads.

Engineering and Custom Fabrication

We perform Finite Element Analysis (FEA) on the Arc Rib design to validate its structural response to various external and internal loads, particularly for deep burial applications.

Customization Scope: Full configuration of internal layout, including anti-syphon pipework, custom electrical bussing, and integration of specialized chemical treatment equipment (e.g., chlorination units).

We offer full-service installation planning, including anchor bolt patterns and foundation loading specifications for the client's civil engineering team.