Synergistic System Integration and Control

This station is a unified, packaged booster system that houses separate, dedicated pump trains and controllers for both domestic (potable) water supply and fire suppression. While sharing a single structural skid or modular enclosure, the two systems operate independently to meet their respective code requirements (constant pressure for domestic; fixed-speed, code-compliant reliability for fire).

The system features intelligent control logic that prioritizes fire demand. Upon receiving a fire alarm signal, the domestic pumps are typically shut down to prioritize power and water flow to the fire pumps, ensuring that the most critical safety function is never compromised.

Specification Table: Integrated Domestic/Fire Station

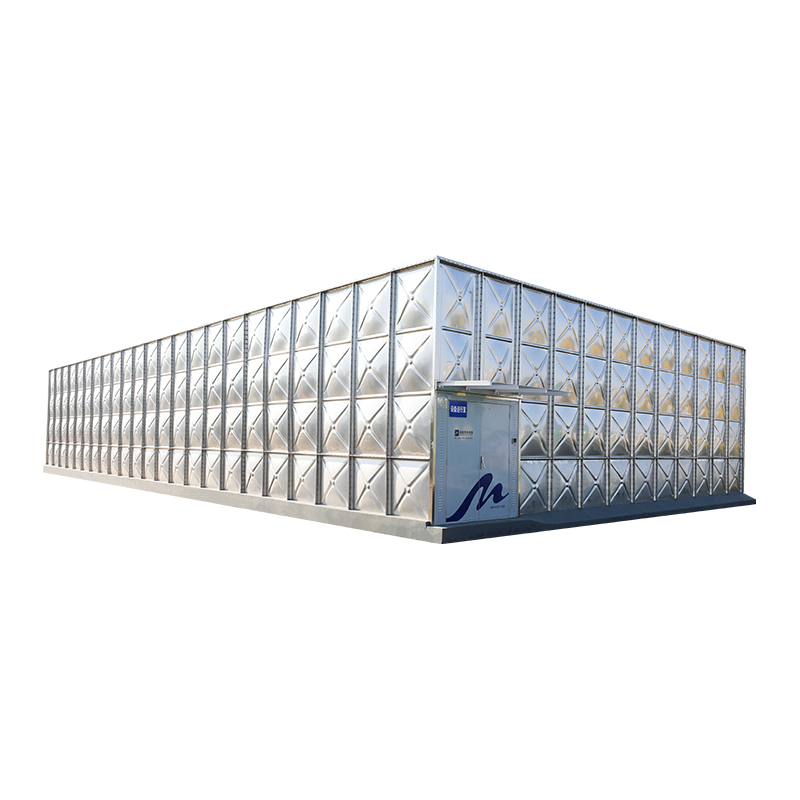

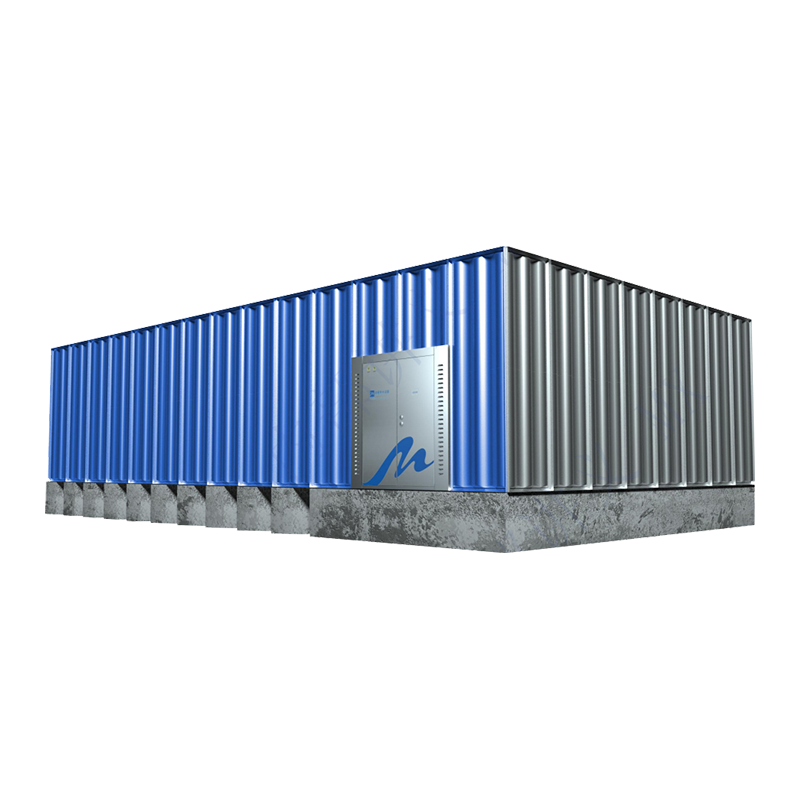

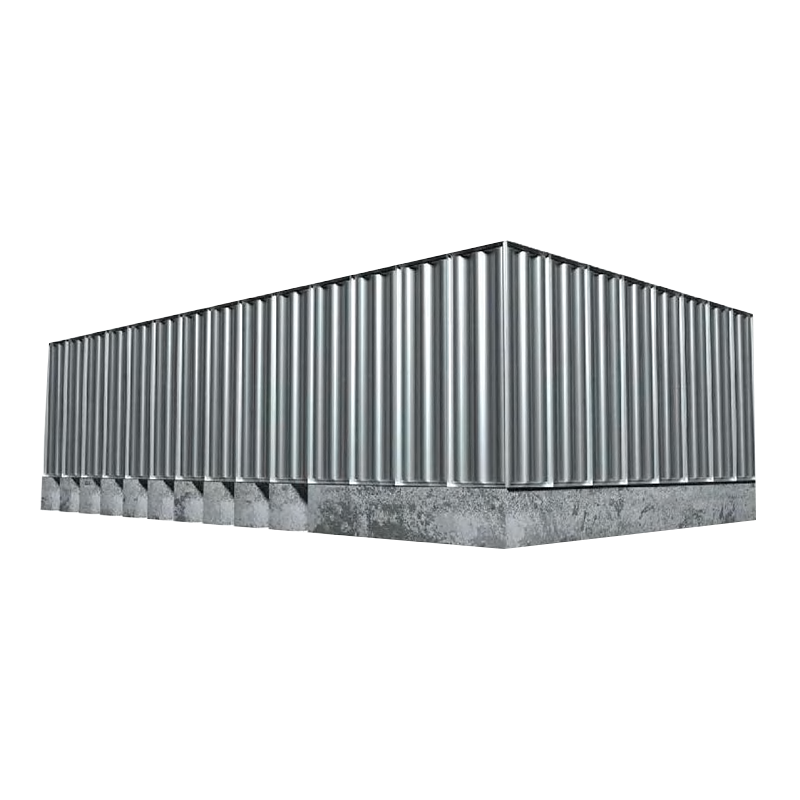

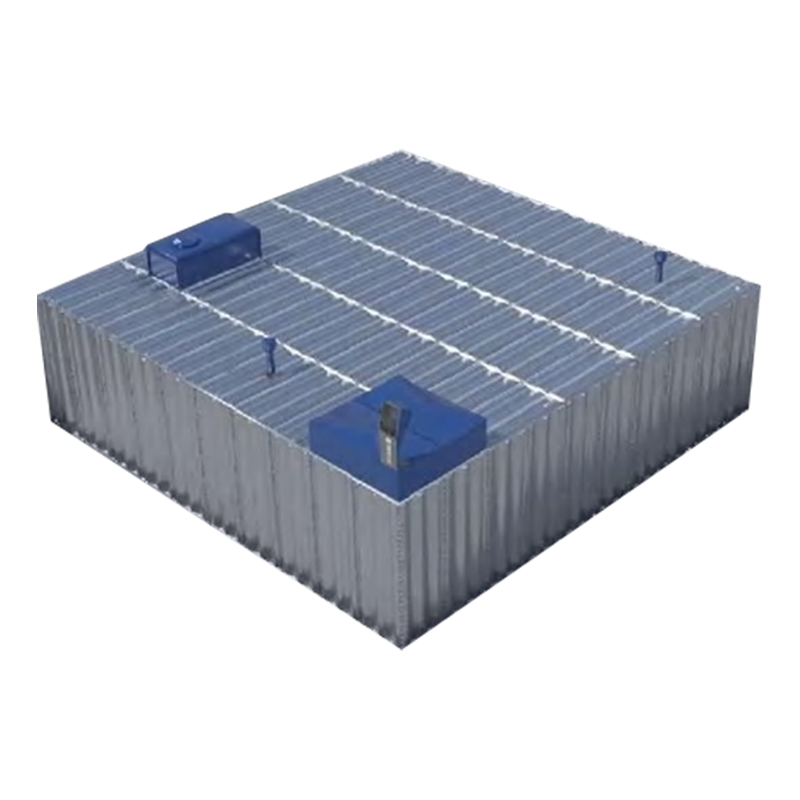

| Configuration | Modular Skid or Enclosed Box-Type Station |

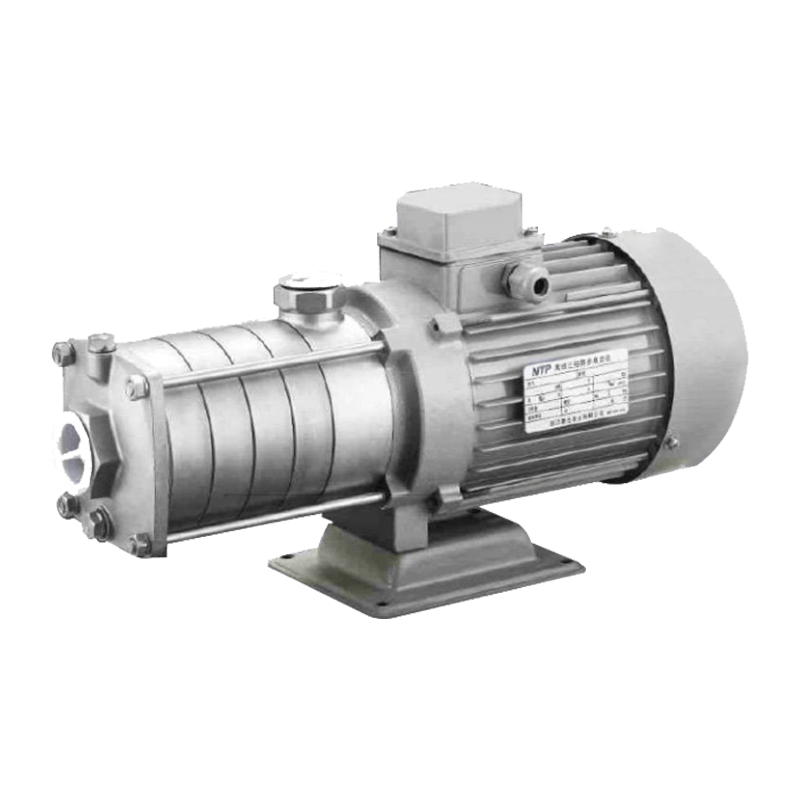

| Pumps (Domestic) | VFD Controlled Multi-Stage Centrifugal (High Efficiency) |

| Pumps (Fire) | NFPA/UL/FM Compliant (Electric/Diesel Redundancy) |

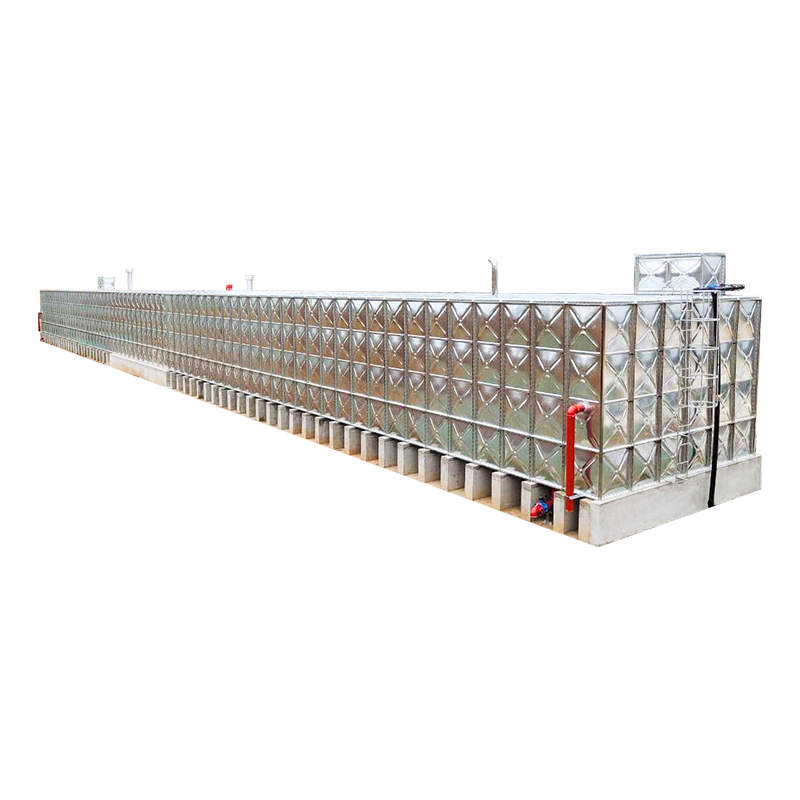

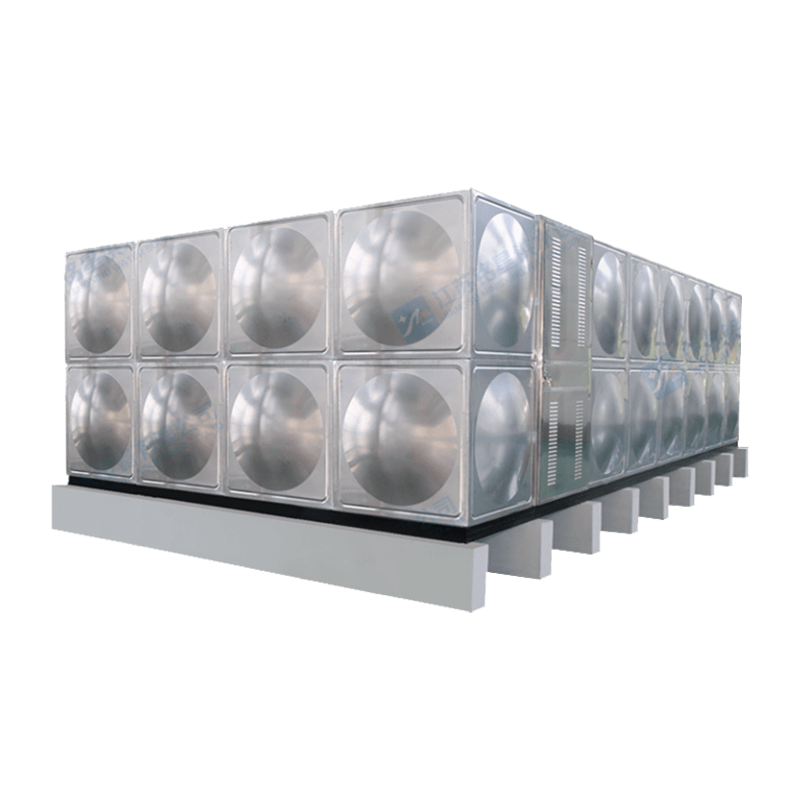

| Integration Point | Common Suction from a Domestic/Fire Water Tank |

| Safety Logic | Automatic Fire Demand Over-Ride (Prioritization) |

| Control Systems | Separate VFD Controller and UL Listed Fire Pump Controller |

| Compliance | NFPA 20, Local Building Codes, Potable Water Standards |

| Monitoring | Integrated LeShui Smart Water IoT Platform |

Application Fields

- New residential and mixed-use developments needing to optimize the pump room footprint.

- Hospitals and institutional buildings where system uptime for both domestic and fire is critical.

- Corporate office parks and large campuses requiring centralized, high-volume water services.

- Integration with our Bidirectional Arc-Ribbed Super Rigid SW Water Tank for complete water management.

- Retrofit projects needing to consolidate old, disparate pump systems into a single, efficient unit.

Engineering and Custom Fabrication

Our engineering team specializes in ensuring that the combined station meets the structural integrity and space utilization requirements of both pump types without compromising the performance of either.

Customization Scope: We offer specific pump combinations (e.g., Vertical Multi-Stage for high head domestic, Horizontal Split Case for high flow fire), custom manifold placement, and integration of specialized water treatment modules (e.g., UV or chemical dosing) onto the domestic train.

The system undergoes a full operational Factory Acceptance Test (FAT) that includes a simulated fire test to verify the safety priority logic.