General Prefabrication and Custom Assembly

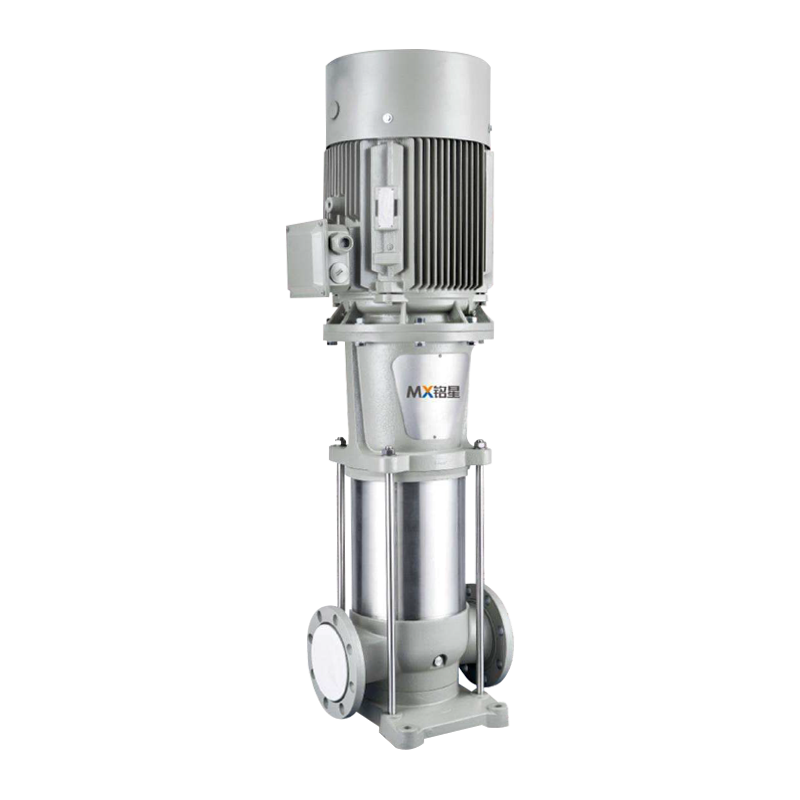

The Integrated Prefabricated Pump Station is the overarching term for all factory-built, ready-to-install pumping units. This concept emphasizes off-site construction, modularity, and rapid on-site commissioning across any application (water, sewage, fire).

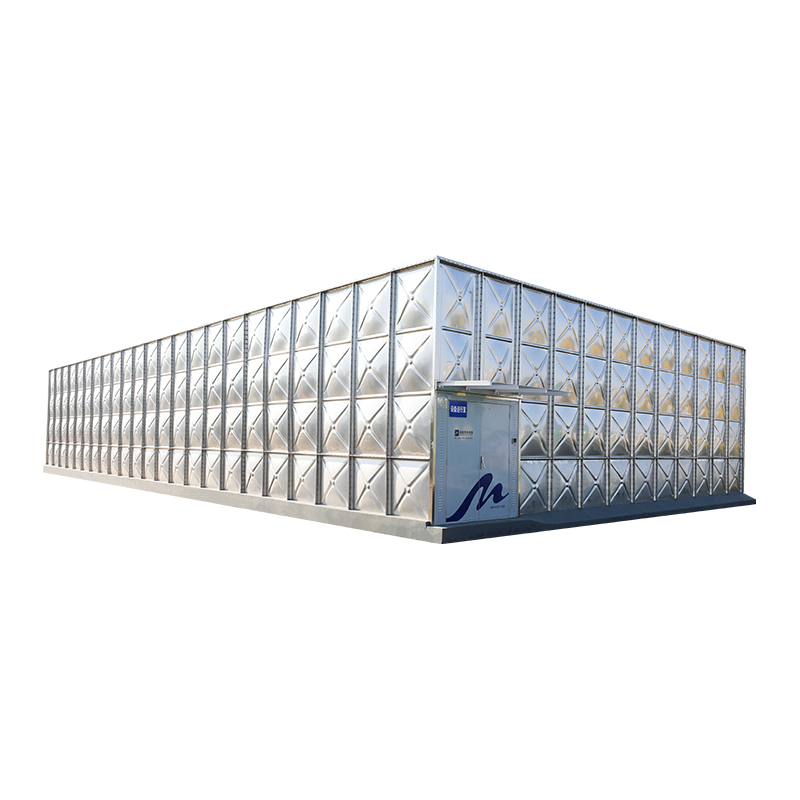

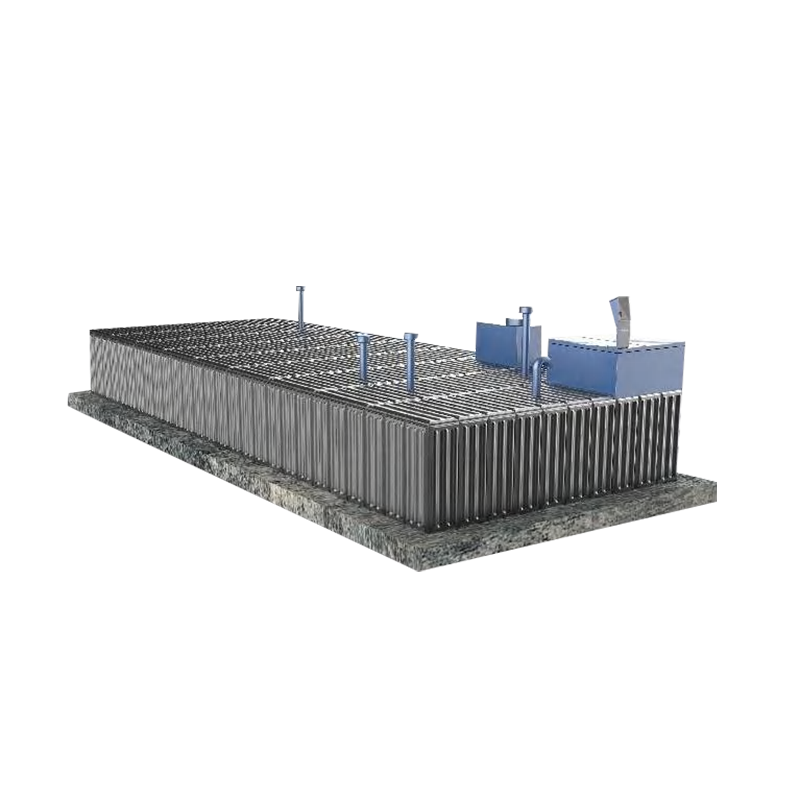

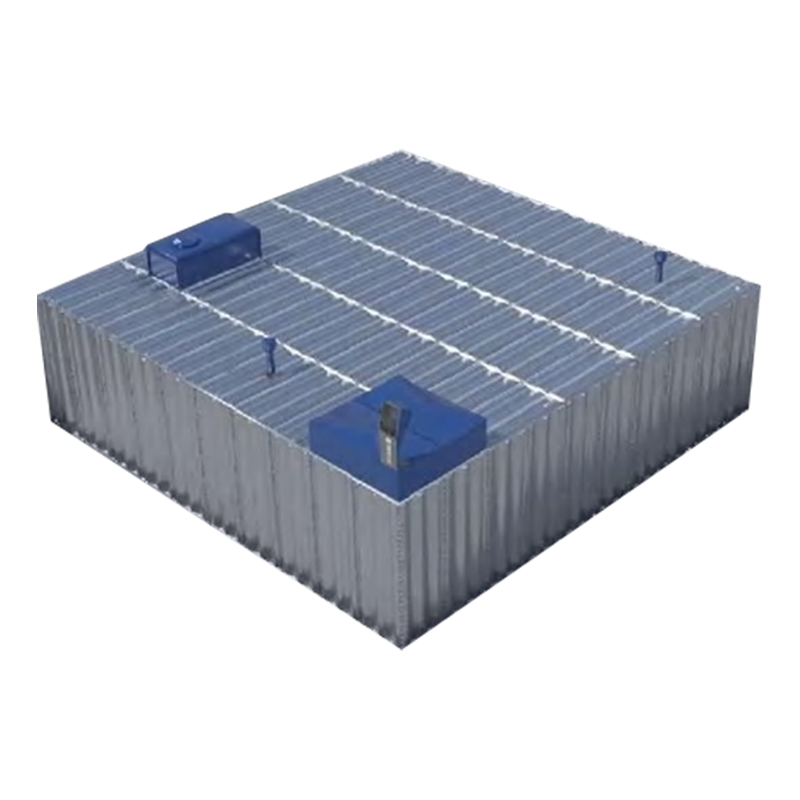

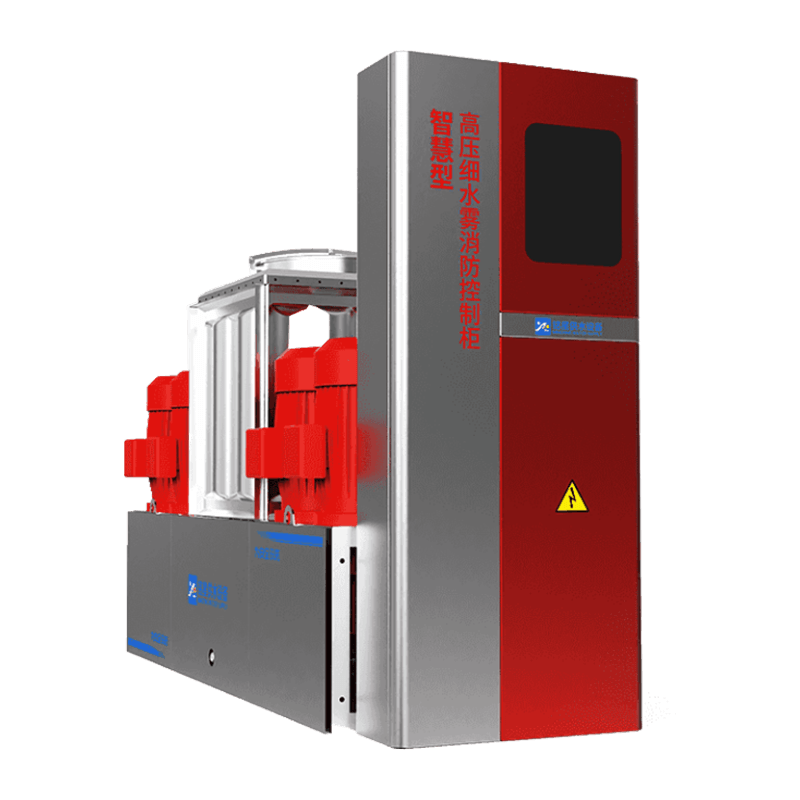

These stations are engineered to be delivered as a single unit or a small number of interconnected modules. Prefabrication includes not only the pumps and controls but also the necessary structural components (skid, enclosure, internal platform, lighting, ventilation), providing a complete functional system.

Specification Table: Prefabricated Pump Station

| Construction | Modular, Factory-Assembled, and Tested |

| Applicable Functions | Water Supply, Fire Protection, Sewage Lifting, Transfer |

| Material Options | Steel (Box-Type), GRP/FRP (Sewage), Concrete (Buried) |

| Customization Level | High (Tailored to Flow/Head and Application) |

| Testing | Mandatory Factory Acceptance Test (FAT) |

| Installation Time | Reduced by up to 70% vs. Traditional Construction |

| Integration | Full Integration of Pumps, Controls, and Enclosure |

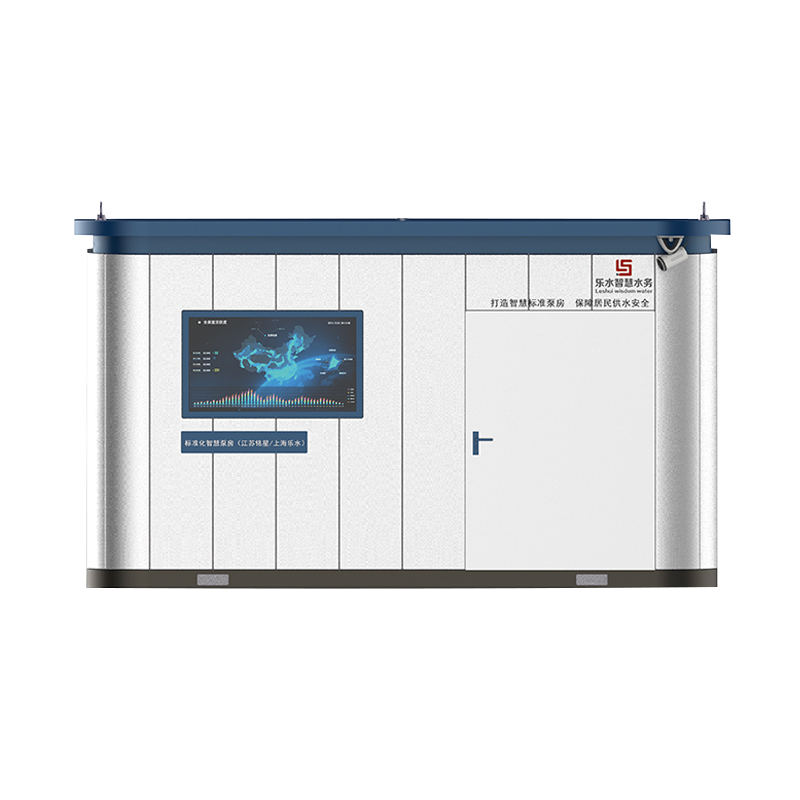

| Monitoring | Standard Integration of IoT Telemetry |

Application Fields

- New industrial facilities and large campuses with strict construction timelines.

- Remote infrastructure projects with limited on-site labor and skilled trades.

- Municipal water distribution centers and sewage lift stations.

- Emergency or temporary pumping requirements that need fast deployment.

- International projects where ease of shipping and simple site setup are necessary.

Engineering and Custom Fabrication

We employ a dedicated project management team to oversee the entire prefab process, from design concept to final FAT sign-off.

Customization Scope: Integration of full automation systems (PLC/SCADA), specific hazardous area electrical classifications (ATEX/Class 1, Div 2), and specialized pump selections (e.g., Small Flow High Pressure Diaphragm Pumps for dosing). We also offer the Outdoor Smart Pump Room as an insulated enclosure option.

All construction processes adhere to ISO 9001 quality management standards.