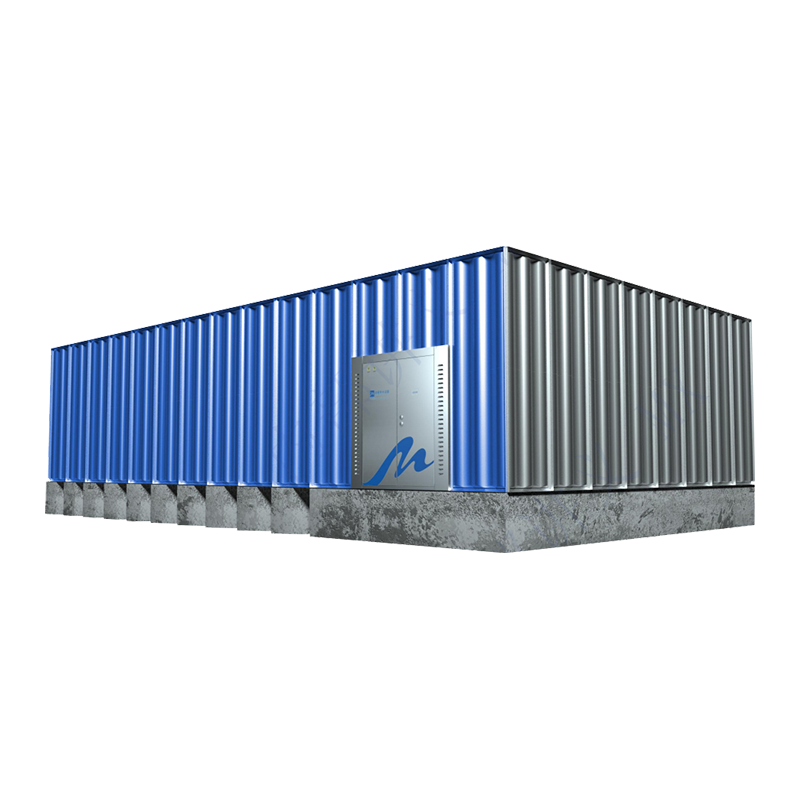

Dedicated Domestic Water Boosting Enclosure

The Integrated Box Water Supply Pump Station is a version of the Box Pump Station specifically focused on domestic (potable) water supply and pressure boosting. It houses a VFD Controlled Constant Pressure Booster System, ensuring a consistent water pressure output while maximizing energy efficiency.

This station is distinguished by its use of hygienic, corrosion-resistant materials (Stainless Steel manifolds, food-grade pumps) suitable for potable water contact, all contained within a secure, tamper-proof, weatherproof box, making it a complete, compliant domestic water solution.

Specification Table: Box Water Supply Station

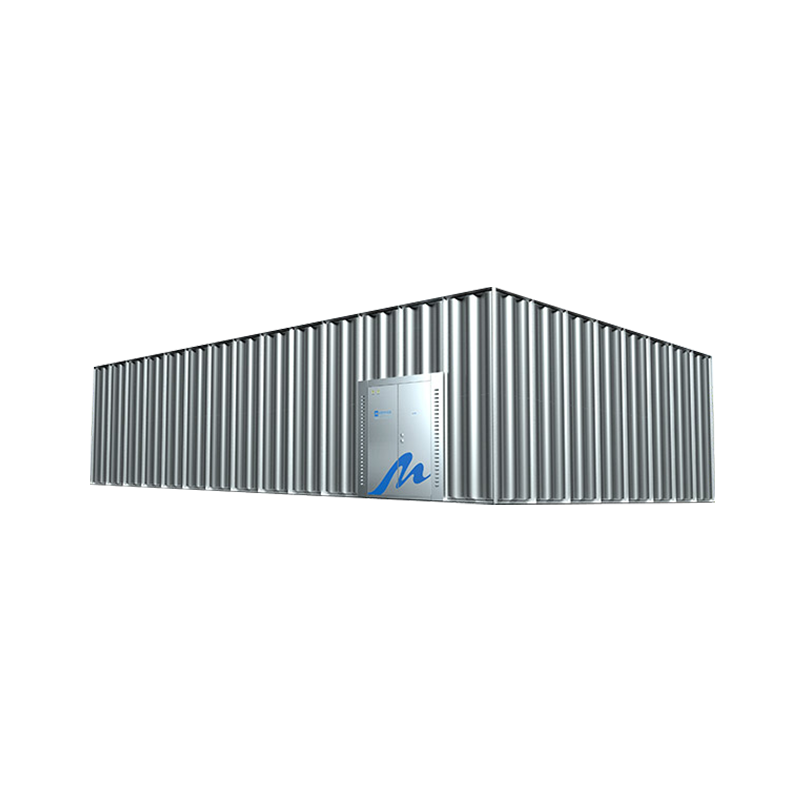

| Configuration | Self-Contained, Weatherproof Box |

| Function | Domestic Water Pressure Boosting (Constant Pressure) |

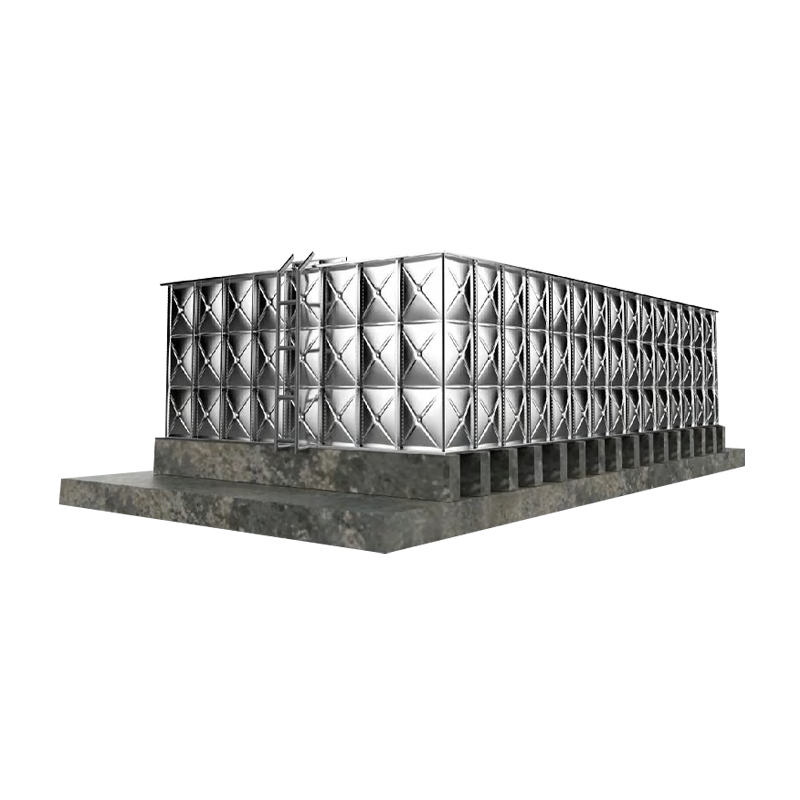

| Pumps | Hygienic Vertical Multi-Stage Centrifugal Pumps |

| Manifold Material | 304 or 316 Stainless Steel (Potable Water Compliant) |

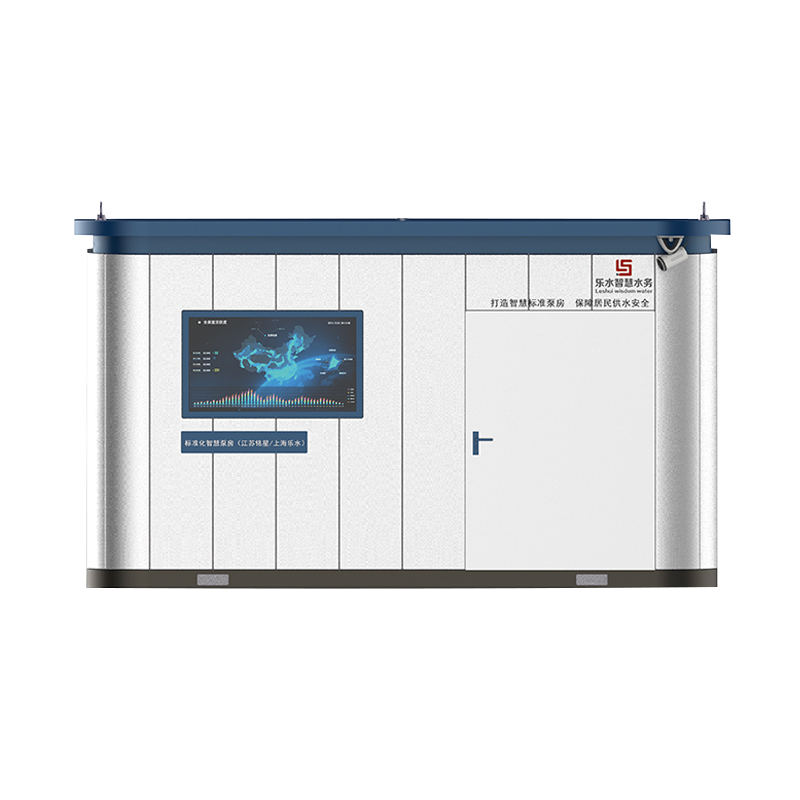

| Control System | VFD with PID Loop Control for Constant Pressure |

| Protection | Non-Negative Pressure (Tank-Type) or Direct Connection Logic |

| Monitoring | Remote Data Logging and Alarm Reporting |

| Acoustics | Low-Noise Operation for Residential Proximity |

Application Fields

- Central water boosting for residential communities and small apartment blocks in urban settings.

- Water supply for schools, dormitories, and hospitals requiring a secure and hygienic system.

- Integration into utility corridors or outdoor plant areas with environmental exposure.

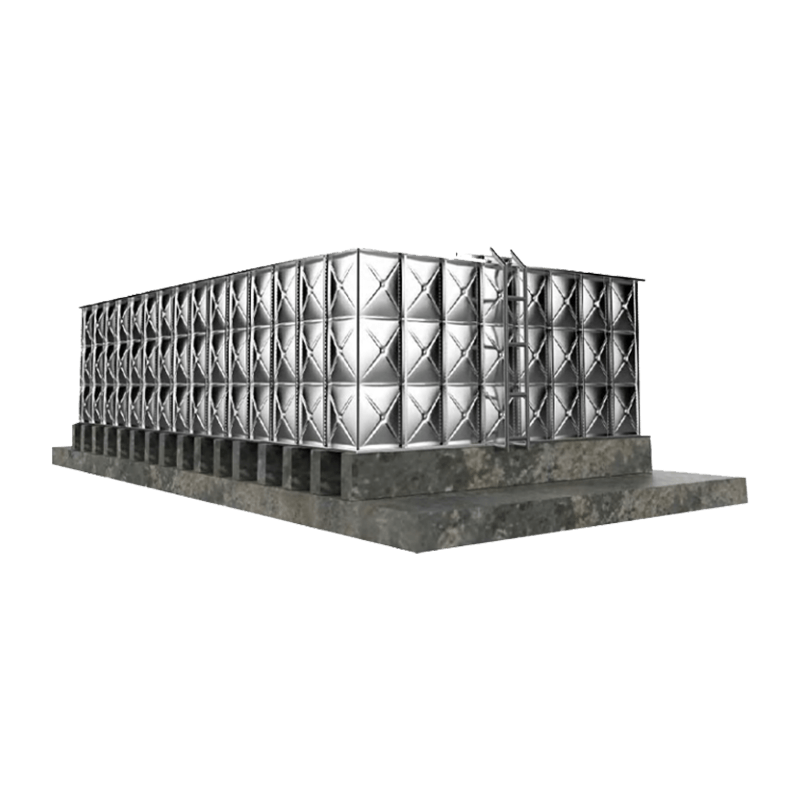

- Serving as the booster unit for water supplied from the Food Grade Stainless Steel Domestic Water Storage Tank.

- Remote commercial facilities needing reliable, self-contained water service.

Engineering and Custom Fabrication

We focus on ergonomic layout within the box, ensuring that the control HMI is at an easily accessible height and all components are clearly labeled.

Customization Scope: Integration of specialized filtration (e.g., UV or carbon) to create a Variable Frequency Water Supply Equipment With Water Quality Improvement Function inside the box, custom exterior finishes, and integration with the client's preferred BMS/SCADA system.

The station is subjected to a final performance test to verify the ±0.02 MPa pressure stability target.