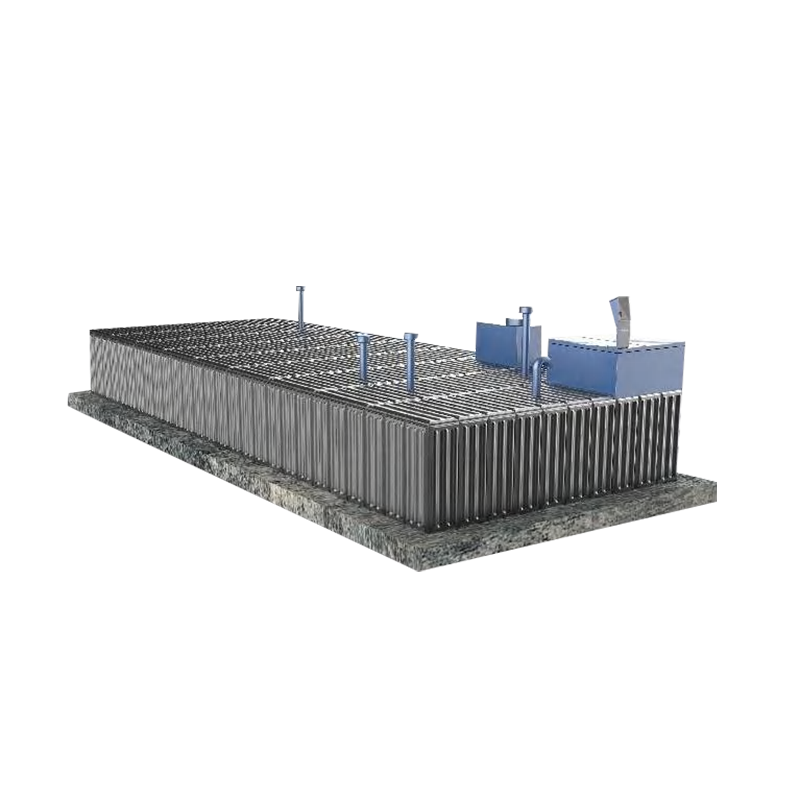

Composite Structure and Ground Integration

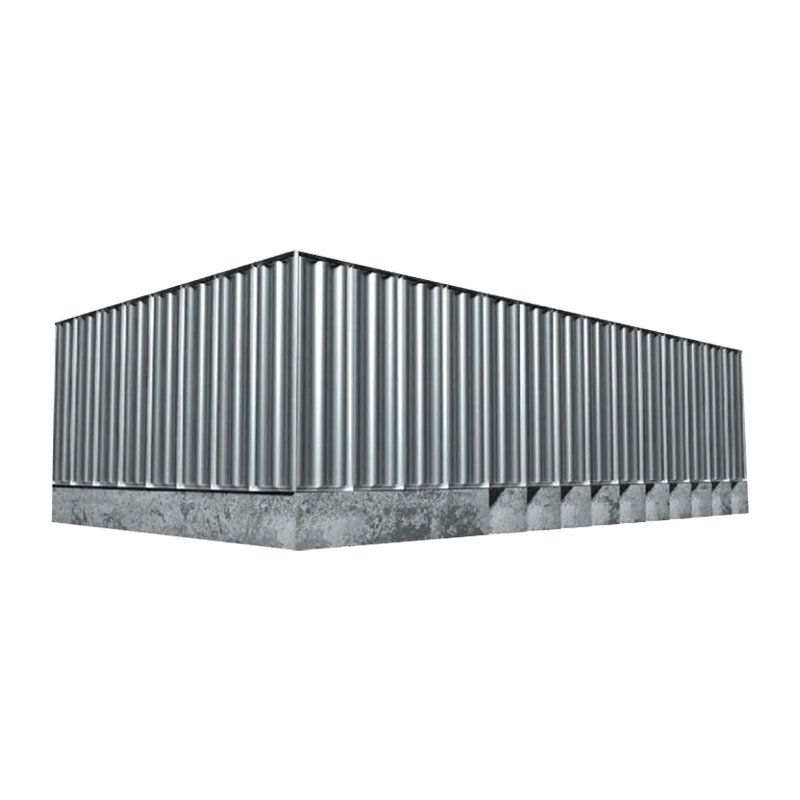

The Mingxing BDF (Bolted-Composite-Film/Fiber) Semi-Buried Fire Water Tank is a specialized structure designed for subterranean or semi-subterranean installation. The "BDF" construction uses a composite layering technique: a robust steel inner shell (often our Arc-Ribbed or HDG sectional design) bolted together, encased by an external reinforced concrete or composite layer for superior resistance to soil pressure and groundwater buoyancy.

This design minimizes the above-ground footprint while providing a dedicated, structurally sound fire water reserve. Being partially or fully buried also naturally keeps the water temperature stable, protecting against freezing.

Specification Table: BDF Semi-Buried Tank

| Installation Type | Semi-Buried or Fully Buried |

| Structure | Composite (Inner Steel + Outer Concrete/Composite Liner) |

| Inner Shell Material | HDG Steel or Arc-Ribbed Steel (For Enhanced Strength) |

| External Load Rating | Designed to Withstand Soil & Groundwater Hydrostatic Pressure |

| Function | Dedicated Fire Water Reserve (Mandatory Segregation) |

| Access | Watertight Access Manhole Flush with Ground Level |

| Anti-Buoyancy | Engineered Foundation/Anchor System Required |

| Compliance | Local Fire and Civil Engineering Codes for Burial |

Application Fields

- Fire water reserves for urban areas where land is expensive and surface space must be maximized.

- Aesthetic-sensitive commercial and residential projects where an above-ground tank is undesirable.

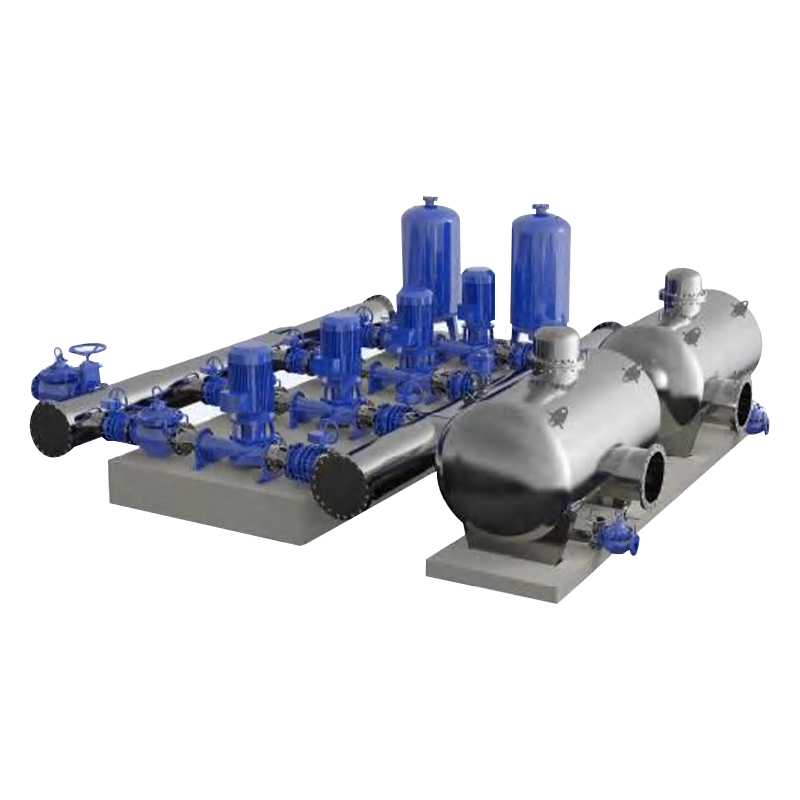

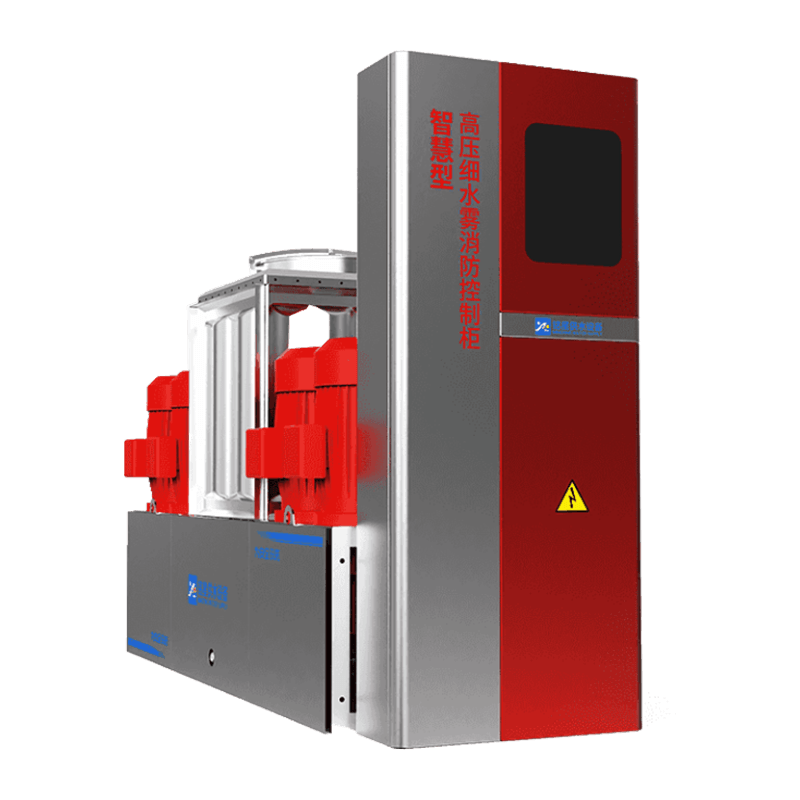

- Integrated into the Mingxing Buried Integrated Fire Pump Station.

- Storage systems in areas with strict height restrictions or high wind loads.

- Sites where temperature stability is required to prevent water freezing or overheating.

Engineering and Custom Fabrication

We provide specialized civil engineering support, including Finite Element Analysis (FEA) to model soil loads and stress on the BDF composite structure, ensuring long-term integrity.

Customization Scope: Specific load ratings (e.g., for heavy vehicles), custom burial depths, and the integration of internal access shafts for connection to Buried Intelligent Integrated Pumping Station pump systems.

The construction process involves a multi-stage quality check on the steel shell assembly and the application of the external waterproofing layer.