Tank-Coupled, Single-Block Fire Solution

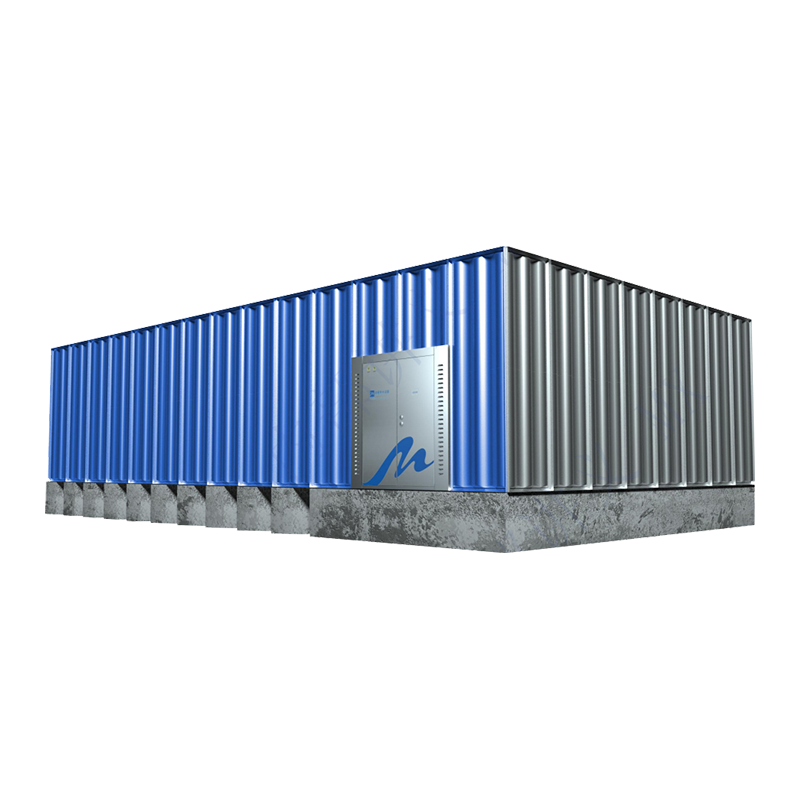

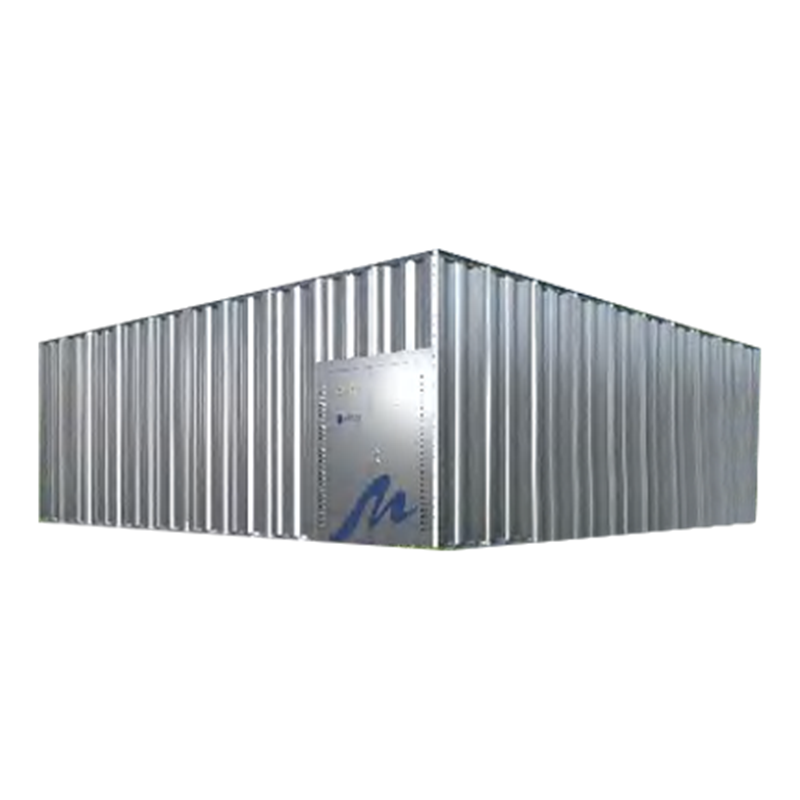

The Mingxing Tank-Type Integrated Fire Pump Station is a configuration where the fire pump set (pumps, controllers, valves) is physically and structurally coupled to the fire water reserve tank (usually a sectional tank like the Bidirectional Arc-Ribbed SW Tank or HDG Bolted Tank). The pump room is either an integrated compartment of the tank structure or sits directly adjacent, forming a cohesive, single-block unit.

This configuration provides maximum structural efficiency by utilizing the tank foundation for the pump equipment, eliminating the need for a separate pump house slab and maximizing the Net Positive Suction Head Available (NPSHa) by placing the pumps directly at the tank outlet.

Specification Table: Tank-Type Fire Station

| Configuration | Pump Room Structurally Attached to/Integrated with Tank |

| Tank Type | Sectional (HDG, SS, Arc-Ribbed) or Custom Design |

| Suction Integrity | Optimized Short Suction Piping (Maximized NPSHa) |

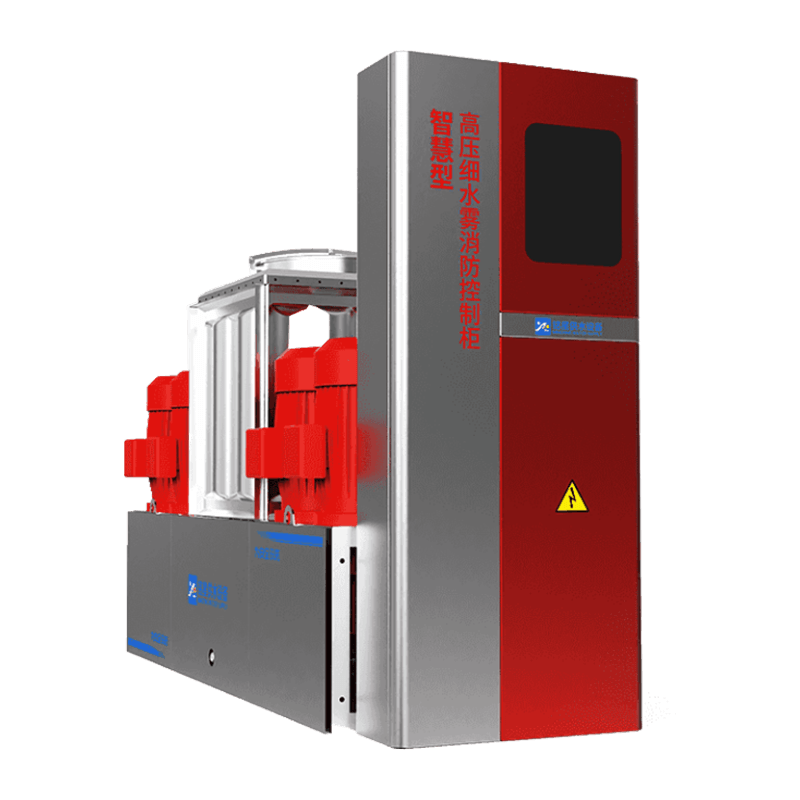

| Pumps | Vertical or Horizontal Fire Pumps (UL/FM Certified) |

| Footprint | Combined Footprint of Tank + Small Pump Compartment |

| Integration | Factory-Engineered Suction, Discharge, and Control Wiring |

| Safety Feature | Dedicated Isolation and Anti-Vortex Suction Ports |

| Compliance | NFPA 20 and all relevant tank/potable water codes |

Application Fields

- Projects requiring minimal civil work and foundation complexity, as the tank and pump system use one foundation.

- Fire protection systems for remote areas or sites with difficult access for complex construction.

- Logistics parks and warehouses that require a high-capacity, self-contained fire water system.

- Integration for the Domestic/Fire water tank where the domestic pumps are also included in the integrated pump room.

- Any application requiring rapid deployment and a single-source solution for storage and boosting.

Engineering and Custom Fabrication

We use specialized hydraulic modeling to simulate the pump suction conditions under 150% rated flow to verify the NPSHa margin in the integrated design.

Customization Scope: Full range of tank dimensions and pump flows. Integration of advanced features such as automatic tank level monitoring and remote pump control via the Intelligent Fire-fighting platform.

The coupling of the pump set to the tank structure is structurally analyzed to ensure that all load paths are within safety margins.