Turnkey Above-Ground Fire Protection

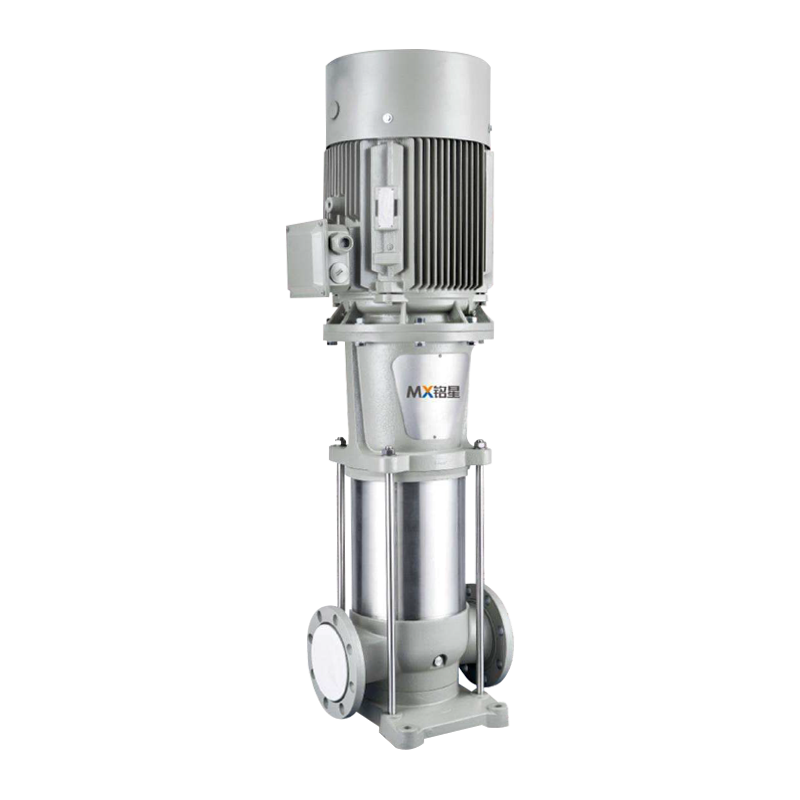

The Mingxing Ground-type Integrated Fire Pump Station is a comprehensive, modular, above-ground fire pump house supplied as a single, fully-equipped unit. It integrates all elements required by fire codes: the fire pump sets (electric, diesel, jockey), the controllers, the pipe manifold, valves, and a protective, insulated enclosure (the pump house).

This solution eliminates the complexity of coordinating multiple vendors (civil, mechanical, electrical) and guarantees that the entire system is factory-engineered and tested to meet NFPA 20 and local codes, making it a true plug-and-play fire safety solution.

Specification Table: Ground-type Fire Station

| Configuration | Walk-in, Insulated, Modular Enclosure |

| Pumps | Horizontal Split Case or Vertical Turbine (UL/FM Certified) |

| Integration | Factory-Piped and Pre-Wired with Single-Point Connection |

| Enclosure Material | Steel Sandwich Panels (Insulated, Fire-Rated) |

| Environmental Control | HVAC/Heating to Maintain Required Operating Temperature |

| Compliance | UL/FM/NFPA 20 and Local Fire Authority Approvals |

| Redundancy | Electric Motor + Diesel Engine (Standard) |

| Customization | Full Range of Flow and Head Certifications |

Application Fields

- Primary fire water supply for large industrial facilities, data centers, and manufacturing plants.

- Remote fire water supply stations for oil/gas storage or large logistics centers.

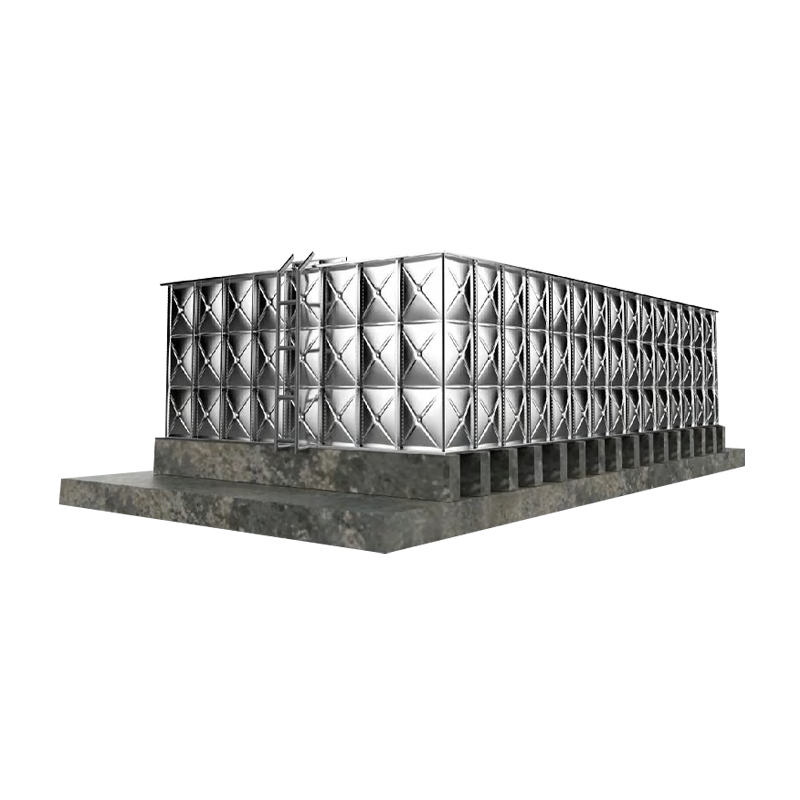

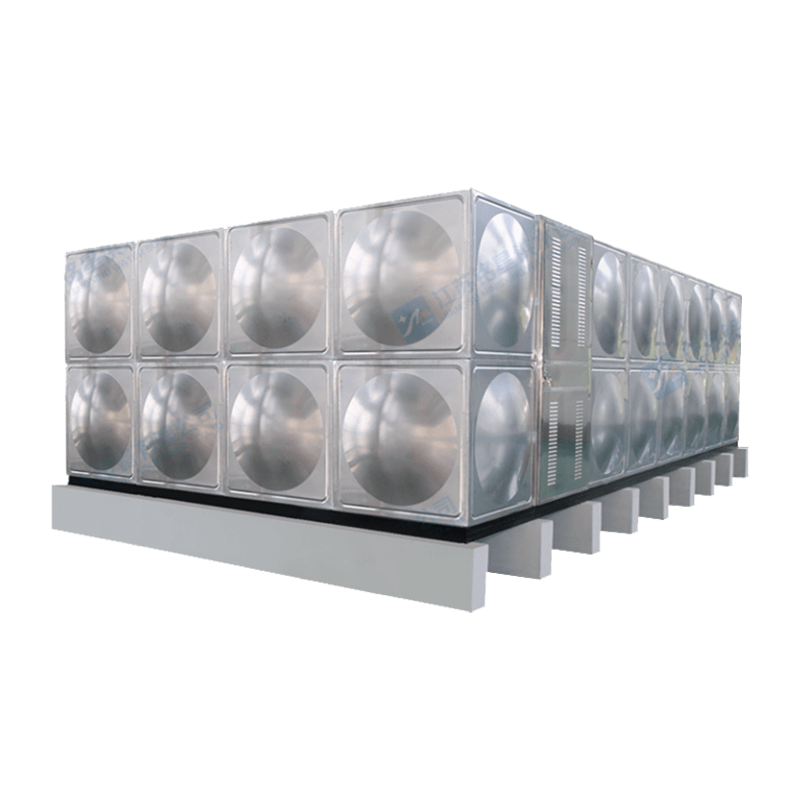

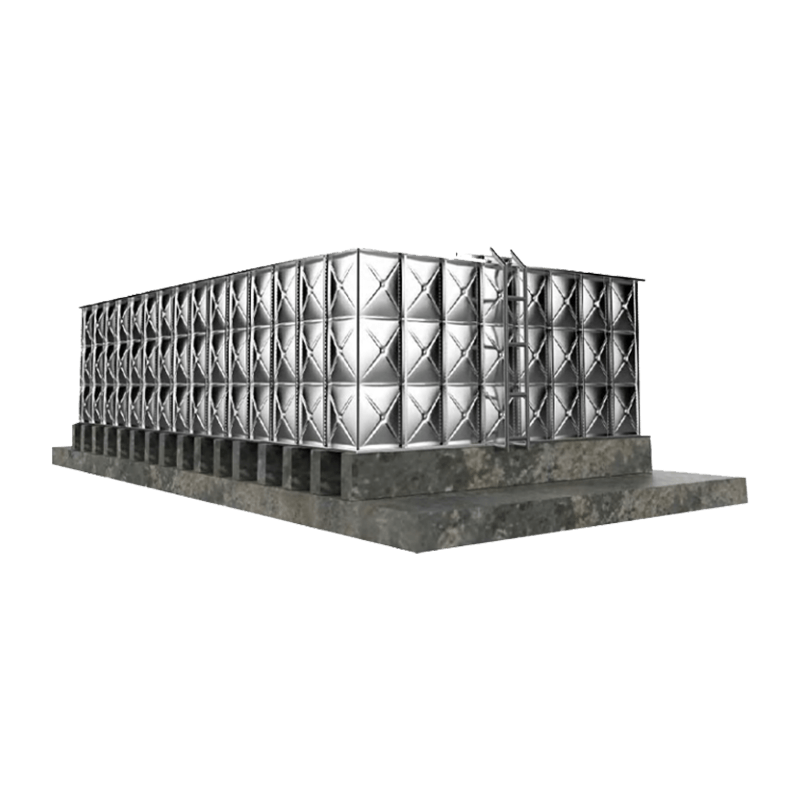

- Dedicated pump house for fire water drawn from the Bidirectional Arc-Ribbed Super Rigid SW Water Tank.

- Rapid deployment of fire safety infrastructure in temporary or phased construction sites.

- Any application requiring a standalone, ready-to-use fire pump system.

Engineering and Custom Fabrication

Internal layout is optimized for NFPA-mandated maintenance clearances around pumps and controllers, ensuring ease of access for service personnel.

Customization Scope: Specific flow/head curve matching, integration of client-preferred control panel brands, custom color schemes, and inclusion of a dedicated fire water meter and test line header.

We perform a complete Factory Acceptance Test (FAT) witnessed by the client, including the 150% rated flow test required by NFPA 20.