Construction Method and Structural Integrity

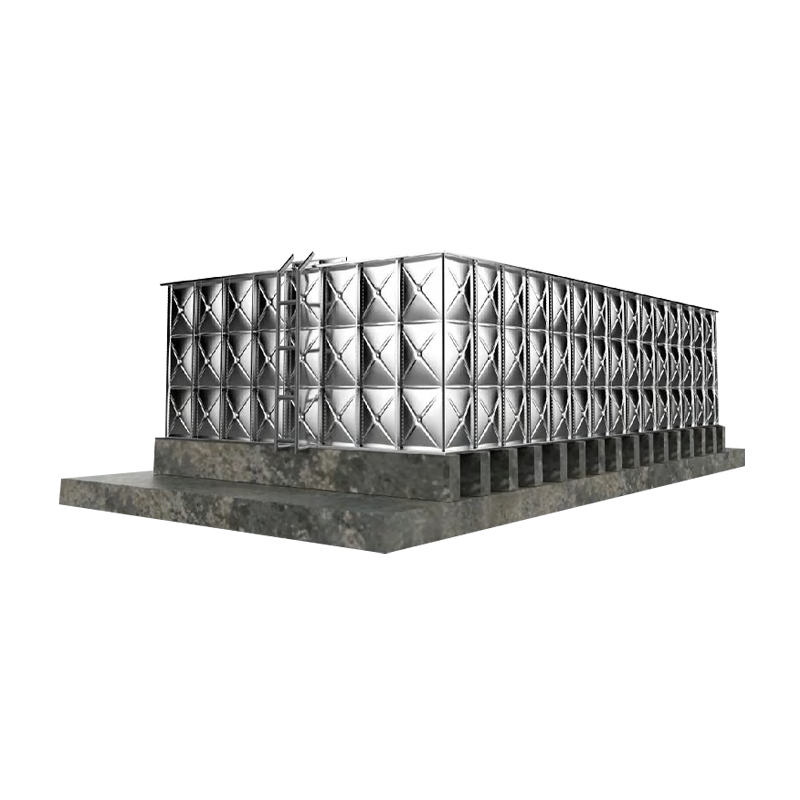

Welded Water Tanks are constructed from steel panels (Stainless Steel or Carbon Steel) that are permanently joined on-site using specialized welding techniques (e.g., TIG, MIG). Unlike bolted sectional tanks, the fully welded structure eliminates the need for internal gaskets and external bolts, providing a monolithic and inherently leak-proof containment vessel.

This construction method yields superior structural rigidity and is often preferred for applications requiring ultra-hygienic conditions (no crevices for bacterial growth) or where the tank's exterior must be perfectly smooth for aesthetic or insulation purposes. They are typically customized in size and shape to maximize fitment in specific indoor locations.

Specification Table: Welded Water Tank

| Capacity Range | 1 m3 to 1000 m3 (Site-specific limits apply) |

| Material Options | 304 or 316 Stainless Steel, Carbon Steel (Lined) |

| Construction Method | On-site Welding (TIG/MIG) |

| Sealing System | None (Monolithic Weld) |

| Tank Shape | Rectangular, Cylindrical, or Custom Geometric Shapes |

| Surface Finish | Polished or Standard Industrial Finish |

| Weld Integrity Testing | Dye Penetrant or Ultrasonic Testing (UT) |

| Compliance | Local Potable Water Regulations (Material dependent) |

Application Fields

- Rooftop potable water storage where space is constrained and a custom fit is needed.

- Storage of ultra-pure water, RO water, and de-ionized water in industrial processes.

- Pharmaceutical and food processing facilities requiring seamless, hygienic interiors.

- Laboratories and specialized chemical storage (with 316 SS and appropriate lining).

- Buffer tanks for pump stations where quick installation of a standard size is required.

Engineering and Custom Fabrication

We employ certified welders and utilize mechanized welding equipment to ensure the highest quality, X-ray-grade welds. All welds undergo Nondestructive Testing (NDT) to verify integrity before the tank is filled.

Customization Scope: Full customization of height, width, and length. Integration of specialized access points, custom nozzle sizing, and internal baffling for flow control or seismic resistance.

Our production includes pre-fabricating panels with precision cuts and forming to minimize on-site labor and ensure dimensional accuracy.