Simplified Path and Maximum Energy Recovery

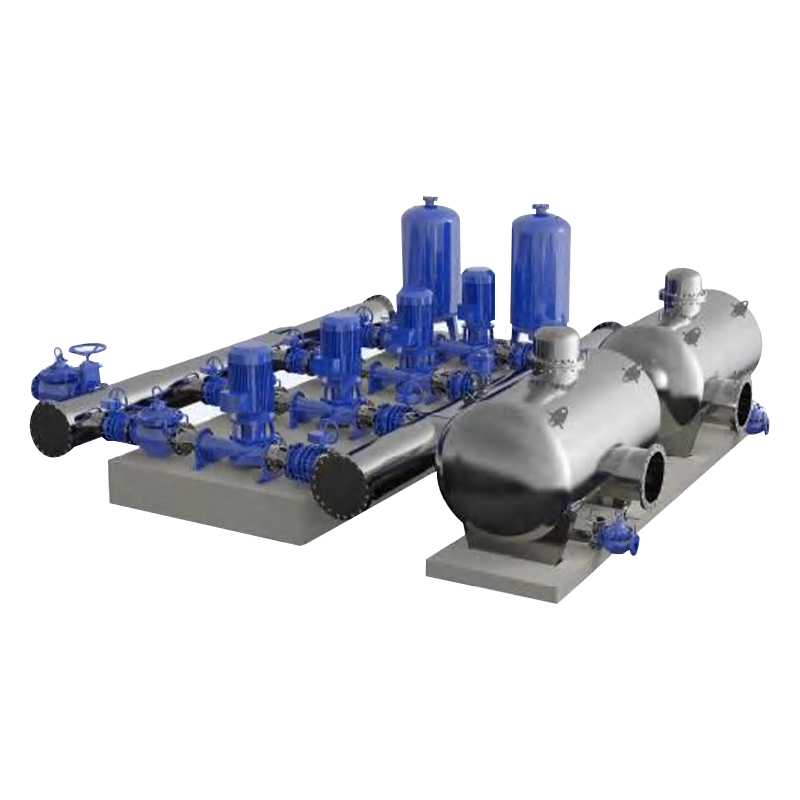

Direct Connection Water Supply Equipment is the simplest form of pressure boosting, designed to augment the municipal water pressure directly into the building system without the need for an intermediate tank or cistern. This is achieved by utilizing the full energy of the municipal pressure and using the booster pump to provide only the residual head required to meet the building's demands.

The system must include a certified backflow prevention assembly (e.g., Reduced Pressure Zone (RPZ) device) to prevent any possibility of non-potable water entering the municipal supply. It is ideal for buildings where the municipal pressure is already substantial and only a small pressure increase is needed.

Specification Table: Direct Connection Equipment

| System Type | Direct On-Line Boosting (No Intermediate Tank) |

| Boost Requirement | Low to Moderate Head Increase |

| Primary Feature | Certified Backflow Prevention Assembly (RPZ/DCVA) |

| Control | VFD Controlled Multi-Stage Centrifugal Pump |

| Flow Range | Small to Medium Capacity |

| Energy Use | Minimal, only supplements existing municipal pressure |

| Footprint | Extremely Compact, Wall-Mount or Small Skid |

| Compliance | Strictly Local Water Authority Backflow Regulations |

Application Fields

- Boosting pressure for small- to medium-sized commercial or residential buildings (e.g., 5 to 15 stories).

- Point-of-use boosting for specific equipment (e.g., large industrial washer, chiller makeup).

- Single-zone pressure stabilization (similar to Roof Pressure Stabilizing Pump Station, but for the entire building).

- Retrofit applications where space is extremely limited.

- Rural areas with reliable source pressure but high elevation requirements.

Engineering and Custom Fabrication

We focus on optimizing the VFD ramp-up and shut-down curves to eliminate water hammer and pressure spikes in the short pipe runs typical of direct connection systems.

Customization Scope: We offer pump sizing based on detailed municipal pressure log data provided by the client, custom-designed skid mounting plates, and integration of specialized inline filtration specific to the municipal water quality.

The entire assembly is pre-tested for pressure containment and VFD control logic accuracy.