Filtration Integration and Continuous Monitoring

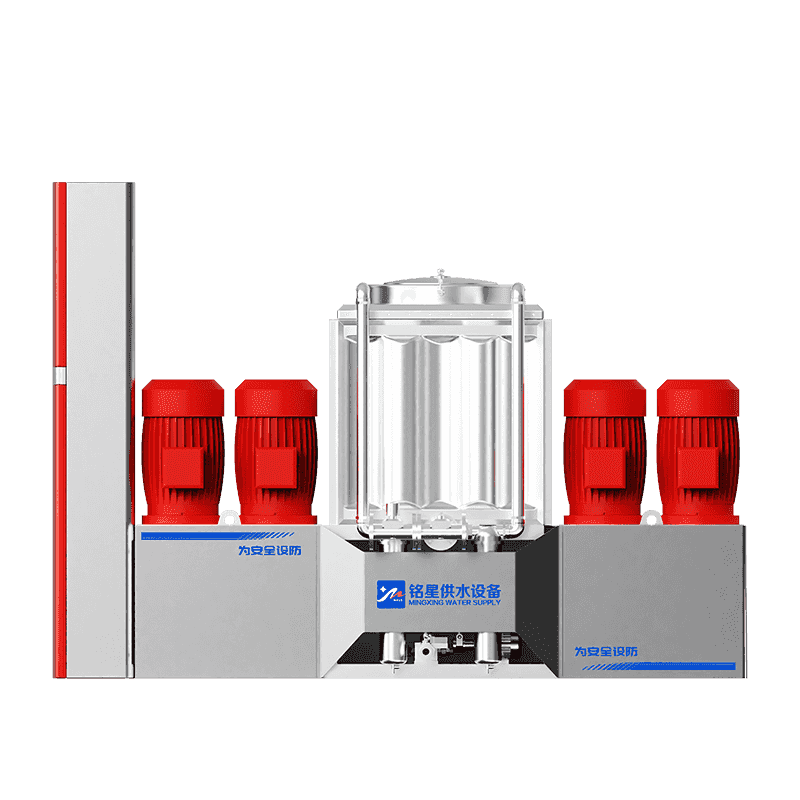

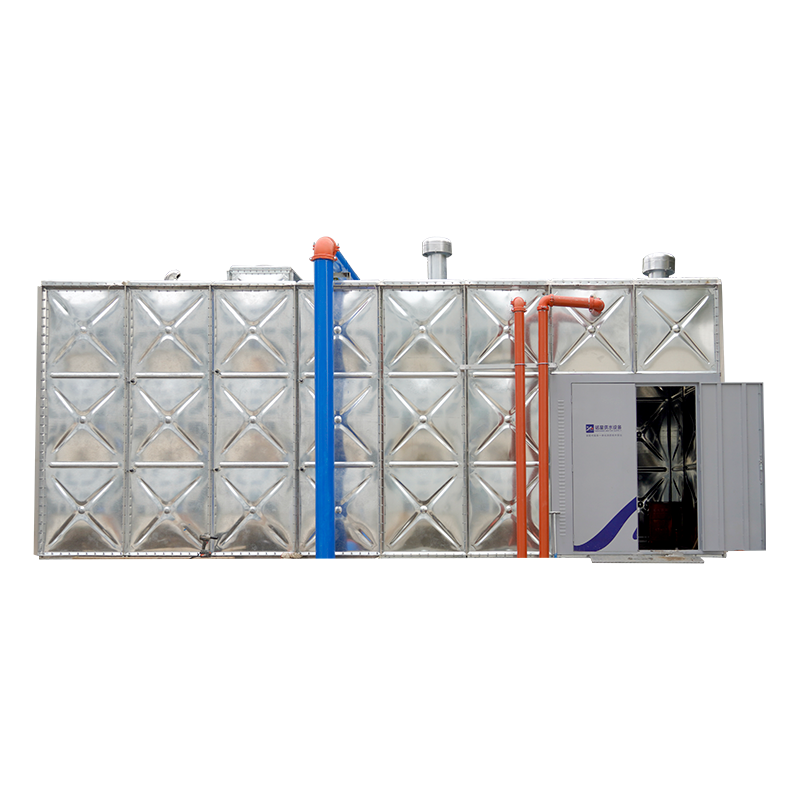

This equipment represents a next-generation booster system that not only utilizes Variable Frequency Drive (VFD) technology for constant pressure and energy savings but also integrates dedicated modules for proactive water quality management. These modules typically include multi-stage filtration (sediment, carbon), UV sterilization, or precise chemical dosing (e.g., chlorine) to neutralize pathogens and remove impurities.

The system's control logic includes continuous monitoring of key water parameters (e.g., turbidity, pH, residual chlorine). If water quality falls outside preset parameters, the system can automatically adjust treatment levels, trigger alarms, or initiate a controlled shutdown, ensuring the safety of the delivered potable water.

Specification Table: VFD + Quality Improvement

| Core Function | Constant Pressure Pumping + Filtration/Sterilization |

| Quality Modules | UV Sterilization, Micron Filtration, Carbon Adsorption, Dosing |

| VFD Efficiency | IE3/IE4 Motors with Smart Speed Control |

| Monitoring Parameters | Turbidity, Residual Chlorine, pH, Temperature |

| Compliance | WHO Guidelines, Local Potable Water Standards |

| Material | Food Grade Stainless Steel Wet-End Components |

| Operation Type | Non-Negative Pressure (Recommended for Water Quality) |

| Control Interface | HMI with Real-Time Quality Logging and Trending |

Application Fields

- Water supply for hospitals and healthcare facilities where waterborne pathogen control is critical.

- Supply systems for schools, universities, and high-density residential buildings.

- Drawing water from reservoirs or secondary sources that require guaranteed post-treatment.

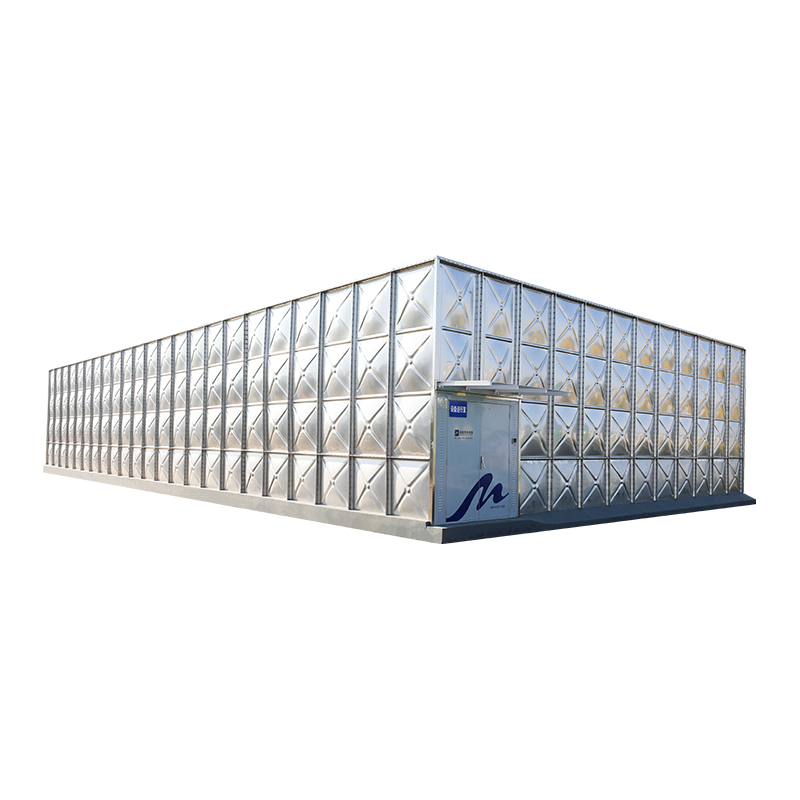

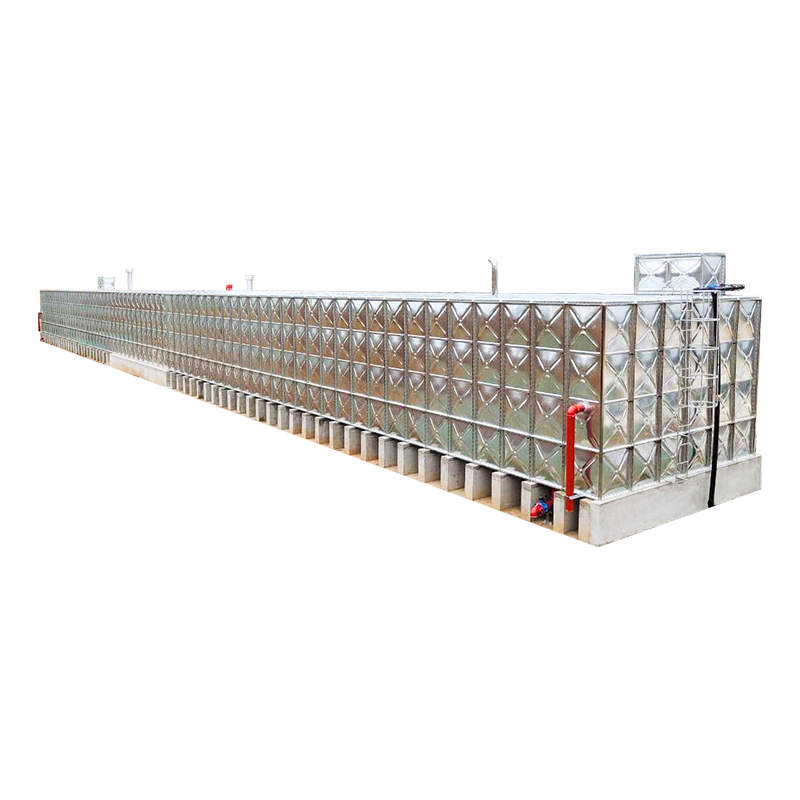

- Integration with Food Grade Stainless Steel Domestic Water Storage Tank for complete hygienic solution.

- Remote communities needing a compact, centralized water treatment and distribution unit.

Engineering and Custom Fabrication

Our R&D team ensures the system's control logic is capable of 'treat-to-demand,' adjusting UV intensity or dosing rate based on instantaneous flow and monitored water quality metrics.

Customization Scope: We offer integration of reverse osmosis (RO) modules for de-salination, custom chemical dosing systems (e.g., pH correction, corrosion inhibitors), and compliance with specific regional water authority testing protocols.

The entire skid is factory-passivated and pressure-tested before shipping to guarantee component integrity and zero-leaching performance.