Extinguishing Principle and Particle Dynamics

The High Pressure Water Mist System is a sophisticated fire suppression technology that utilizes fine water droplets (mist) with a volume median diameter (VMD) typically below 100 μm. The system operates at pressures ranging from 80 to 200 bar (1160 to 2900 PSI), which atomizes water into a highly effective mist.

The primary extinguishing mechanism is cooling (extracting heat via vaporization) and oxygen displacement (inerting the fire zone via steam expansion). The large surface area of the fine mist rapidly absorbs heat and converts to steam, diluting the oxygen concentration around the fire, a highly efficient method for containing or suppressing Class A, B, and C fires with minimal water damage.

Specification Table: HP Water Mist System

| Operating Pressure | 80 to 200 bar |

| Droplet Size (VMD) | ≤100 μm (Volume Median Diameter) |

| Extinguishing Mechanism | Cooling, Oxygen Displacement, Radiation Blocking |

| Water Consumption | Up to 90% less than conventional sprinklers |

| Pipe Material | 316 Stainless Steel (High-Pressure Rated) |

| Nozzle Type | Open or Closed, Certified for Specific Hazard Class |

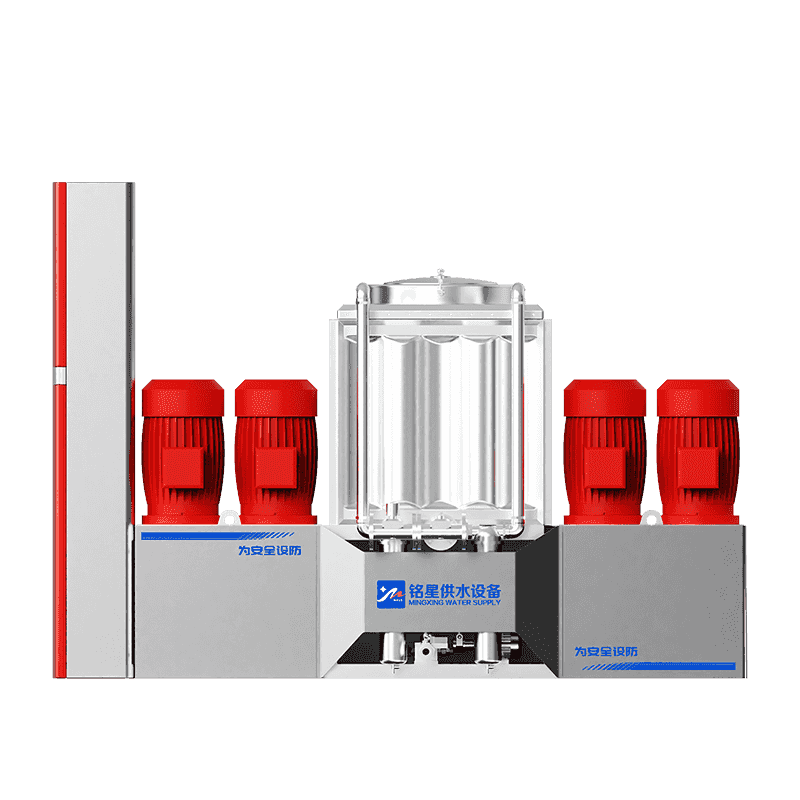

| Pump Type | Positive Displacement or High-Pressure Multi-Stage Plunger Pump |

| Certifications | FM, VdS, or UL for Specific Applications |

Application Fields

- Sensitive data centers and server rooms where minimal water damage is critical.

- Historical buildings, museums, and archives protecting irreplaceable assets.

- Passenger ships, ferries, and cruise liners where space and water supply are limited.

- Industrial machinery protection (turbines, generators, transformers).

- Tunnels, metro stations, and public transport infrastructure with difficult access for traditional fire fighting.

Engineering and Custom Fabrication

We design the hydraulic network using specialized flow modeling software to ensure uniform mist density and coverage in complex geometries, maximizing the cooling and inerting effect.

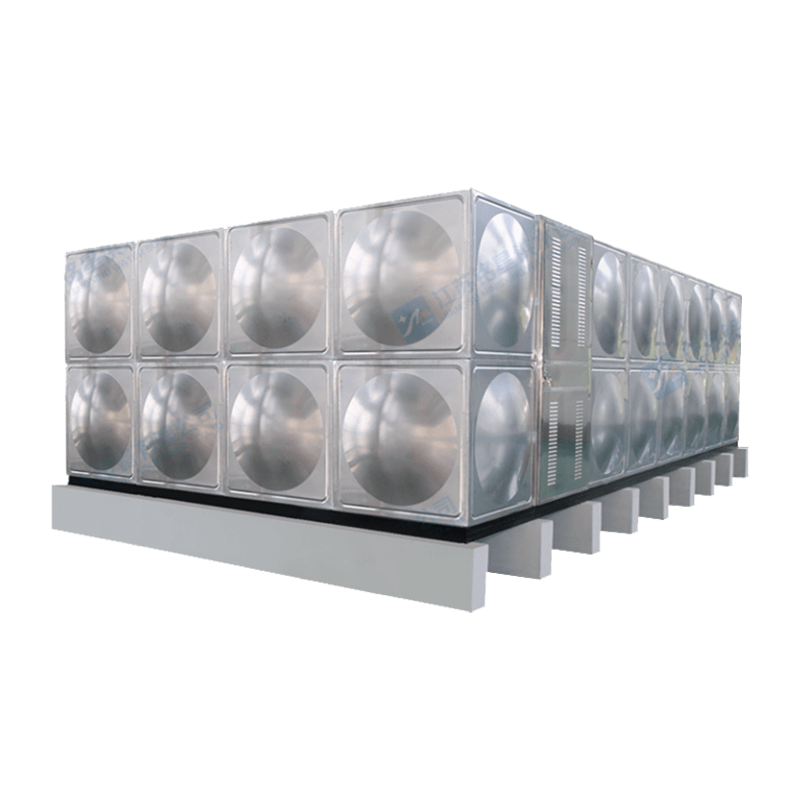

Customization Scope: We offer containerized pump units for offshore or marine applications, custom pump skid sizing for restricted machine room access, and integration with the building's existing fire alarm and security systems (e.g., automatic shutdown of ventilation before discharge).

Full Factory Acceptance Testing involves pump curve verification and high-pressure burst testing of sample pipe sections.