Proprietary Coating and Chemical Resistance

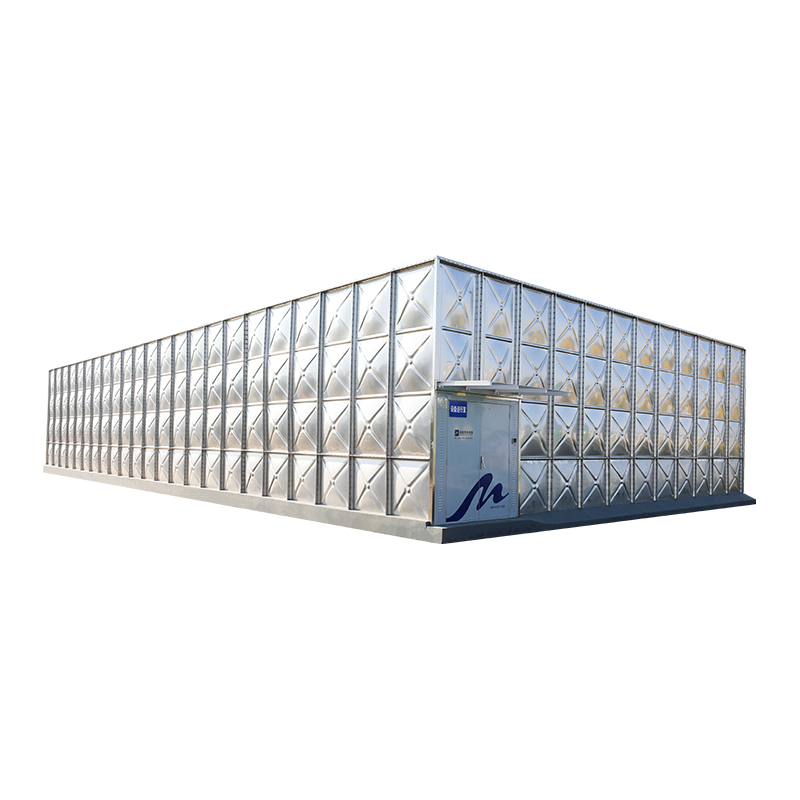

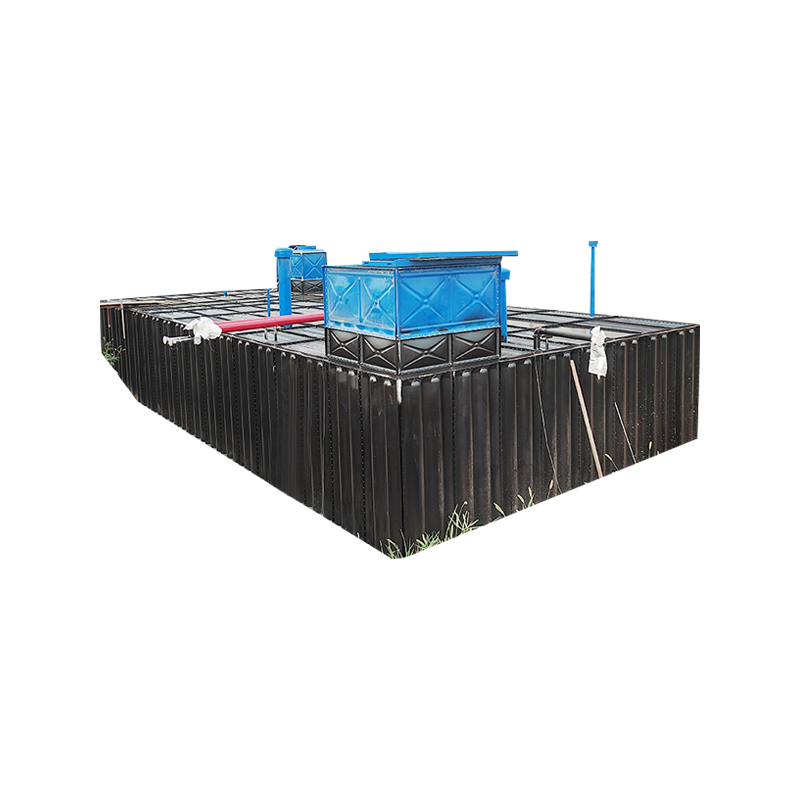

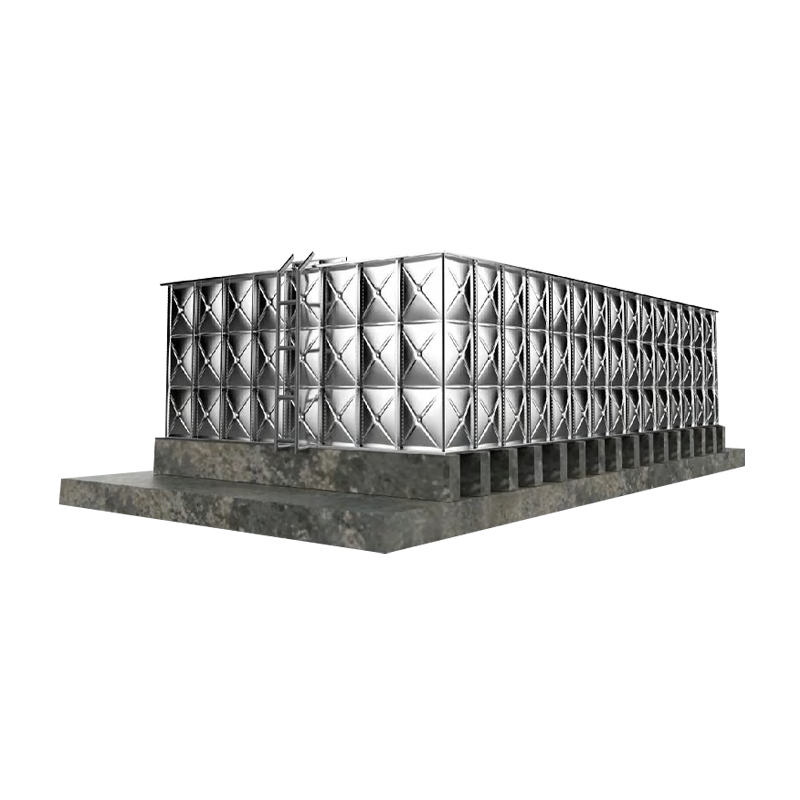

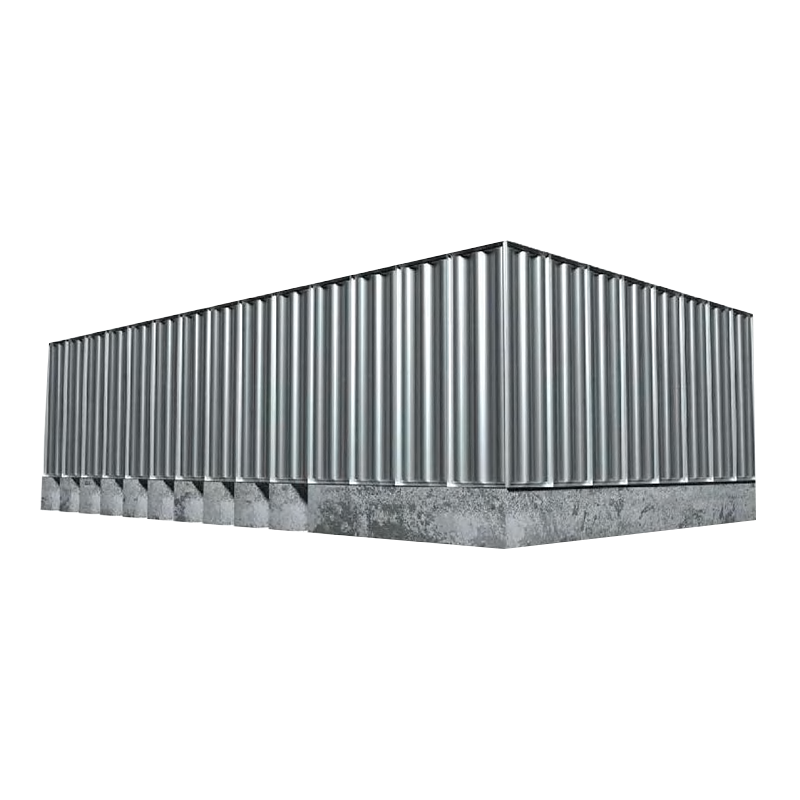

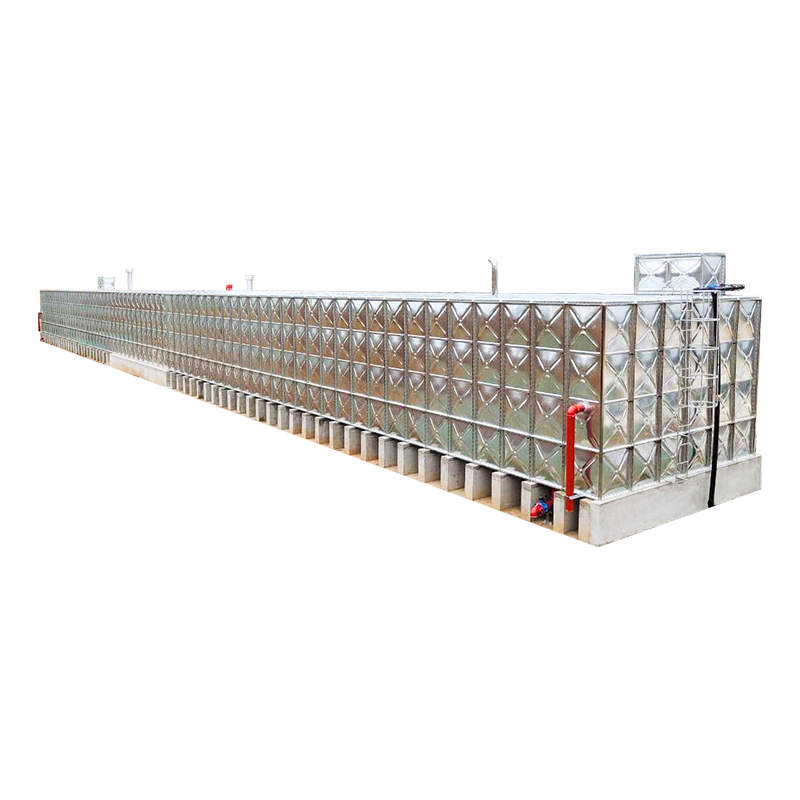

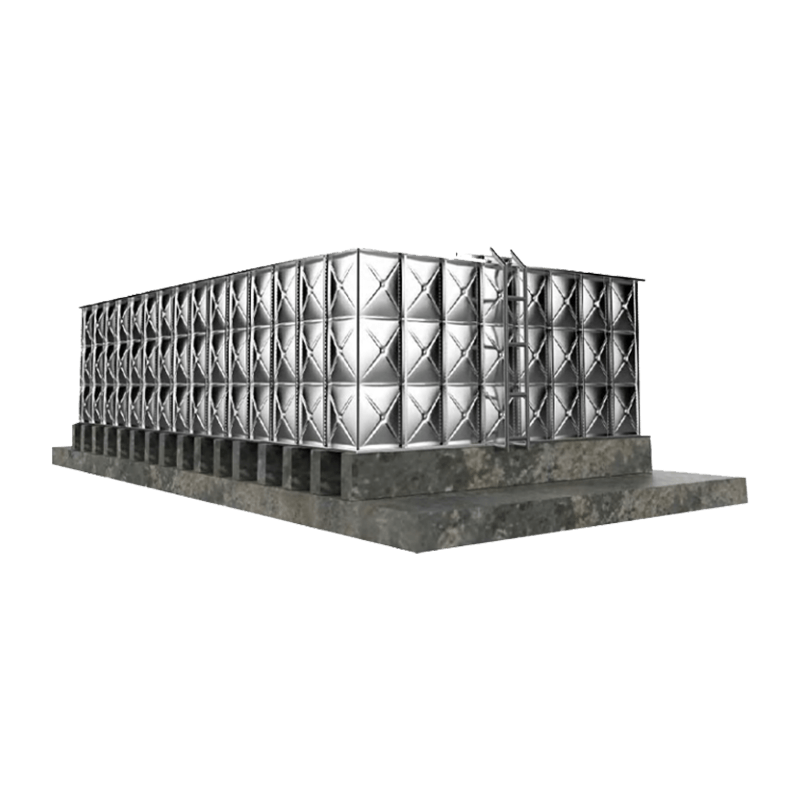

Glass-Fused-to-Steel (GFS) tanks, also known as Glass-Lined-Steel or Enamel tanks, are constructed from steel panels coated with a durable porcelain enamel layer on both the interior and exterior surfaces. This coating is fused to the steel at high temperatures (Approx. 820∘C), creating a permanent, impermeable, and chemically resistant bond.

GFS technology offers a superior long-term, low-maintenance solution, especially in environments where the stored liquid or the external atmosphere is highly corrosive. The construction is modular and bolted, utilizing a specialized sealant at the joints to ensure leak-proof containment.

Specification Table: GFS Tank

| Construction | Modular Sectional, Bolted |

| Coating Material | Glass-Fused-to-Steel (Porcelain Enamel) |

| Coating Thickness | 250 μm to 450 μm (Typical) |

| Color | Standard Dark Green or Blue (Exterior) |

| Chemical Resistance | pH range 3 to 11 (Standard) |

| Application Temperature | −40∘C to +65∘C |

| Standards | AWWA D103-09 (Applicable for Welded Steel Tanks with Glass Coatings) |

Application Fields

- Storage of potable water and wastewater in municipal and remote systems.

- Industrial tanks for slurry, brine, and high-salinity water storage (superior corrosion resistance).

- Biogas and anaerobic digester tanks (high chemical resistance to process fluids).

- Storage for agri-food products and bulk liquids requiring a sterile surface.

- Fire water reserve in locations with high humidity or corrosive salt-air environments.

Engineering and Custom Fabrication

The fusion process is conducted in automated, high-temperature kilns under strict quality control to ensure uniform coating thickness and adhesion strength.

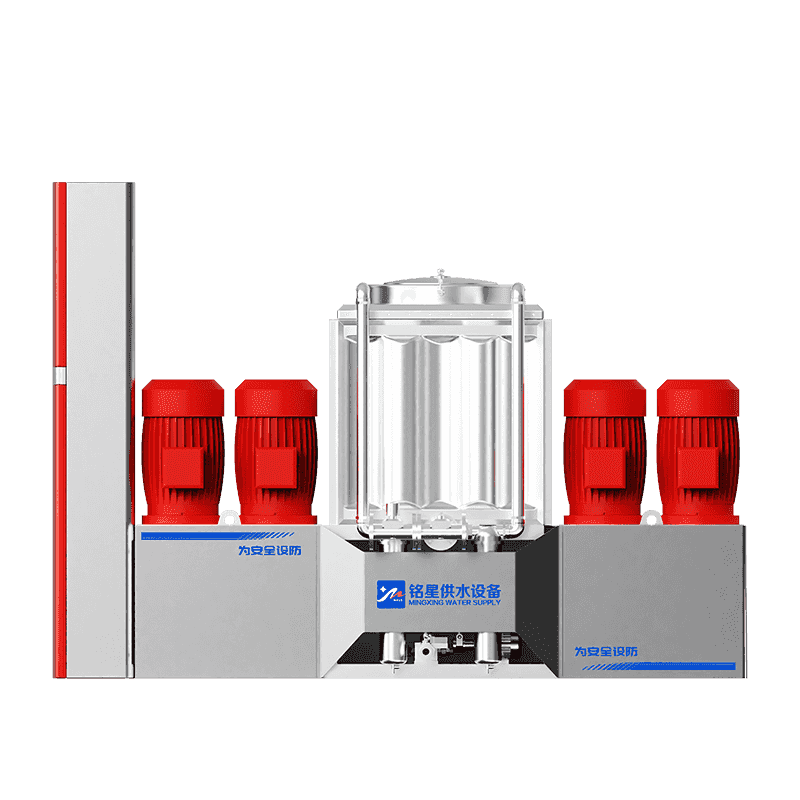

Customization Scope: Specialized coating formulations for extreme pH (acidic or alkaline) environments, custom nozzle placement, and the integration of internal mixers/agitators for slurry applications.

We provide detailed specifications compliant with international GFS standards, including spark testing of the glass layer to ensure no pinholes exist.