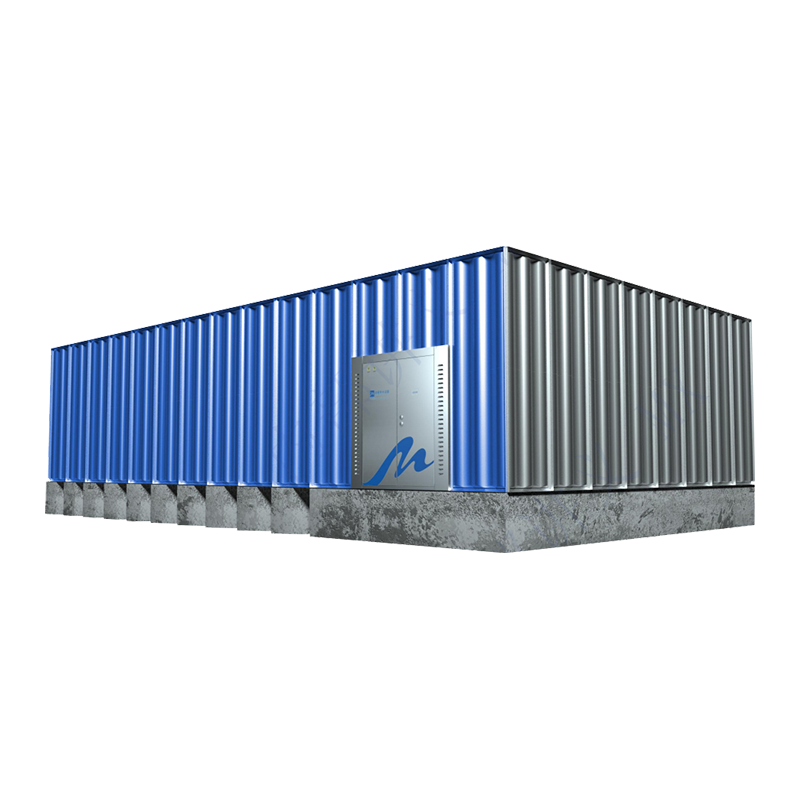

Cistern Integration and Voltage Stability

This system is an evolution of the non-negative pressure concept, utilizing a pressurized, sealed regulator tank (cistern) to act as the primary buffer. The "Voltage Stabilizing" feature refers to the advanced VFD and electrical protection circuitry designed to minimize the impact of voltage fluctuations (brownouts, surges) on the pump and control components, ensuring stable pump operation even with an unstable power supply, common in developing markets.

The sealed cistern ensures the non-negative pressure requirement is met while also providing a small, immediate reserve to smooth out sudden changes in municipal supply flow before the booster pumps engage.

Specification Table: Voltage Stabilizing Tank Type

| System Type | Non-Negative Pressure, Tank-Type Buffer |

| Electrical Feature | Integrated Voltage Protection/Stabilization Circuitry |

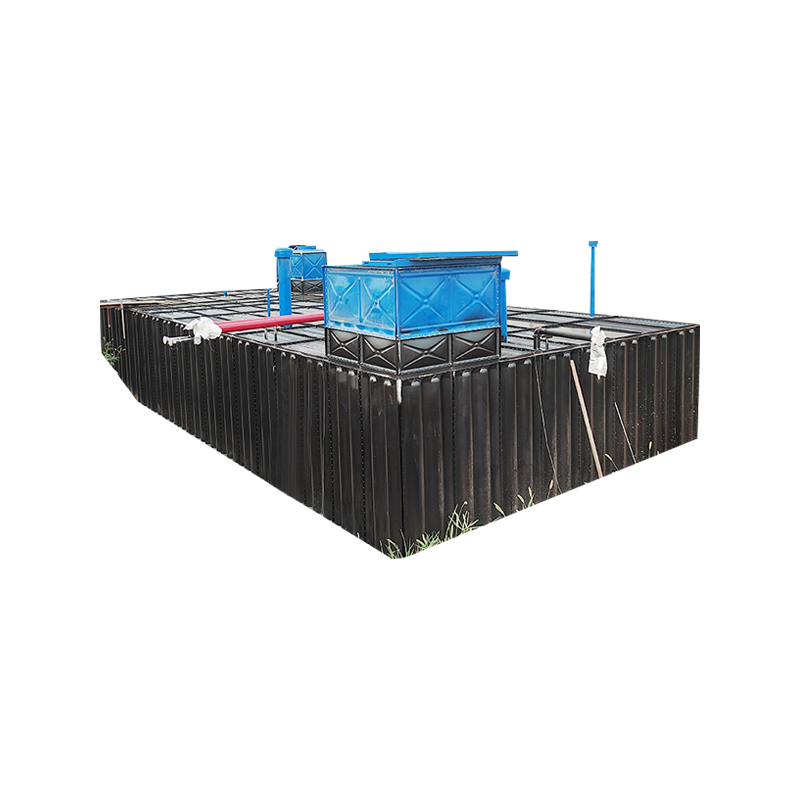

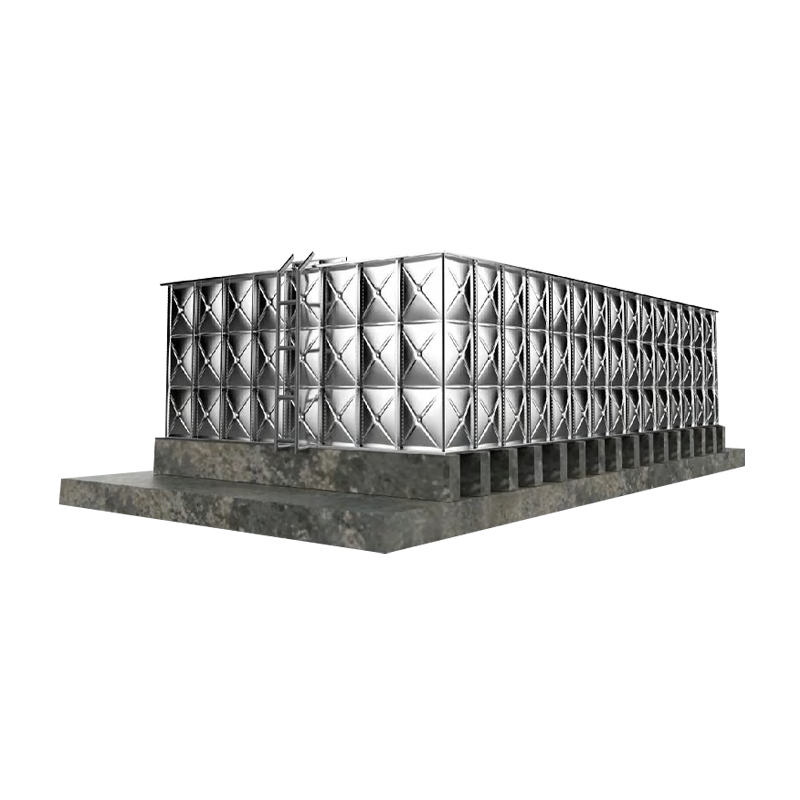

| Buffer Tank | Pressurized, Sealed Cistern for Non-Negative Operation |

| Control | Digital Full Frequency Conversion (VFD) |

| Voltage Tolerance | ±15% (Operational Range, Model Dependent) |

| Safety Feature | Dry-Run Protection, Surge/Brownout Protection |

| Tank Material | Stainless Steel (Hygienic) |

| Monitoring | VFD Health, Voltage Input, Pressure Output |

Application Fields

- Regions with unstable or unreliable public power grids (developing markets, remote areas).

- Industrial processes where precise pressure is mandatory and the power supply is 'dirty' (voltage spikes/drops).

- Supply systems for mid-sized residential complexes needing guaranteed constant pressure.

- Integration into outdoor utility rooms where protection against environmental and electrical factors is required.

- Retrofit applications replacing old pump systems prone to voltage-related failures.

Engineering and Custom Fabrication

We employ specialized electrical engineering to specify and integrate industrial-grade power conditioning modules, ensuring the internal electronics are protected from the volatile power grid.

Customization Scope: Full range of buffer tank volumes, motor voltage/frequency customization for non-standard power grids, and integration with the client's existing lightning protection system.

Factory testing includes running the unit under simulated over- and under-voltage conditions to verify the stability of the pressure output and the integrity of the protection circuitry.