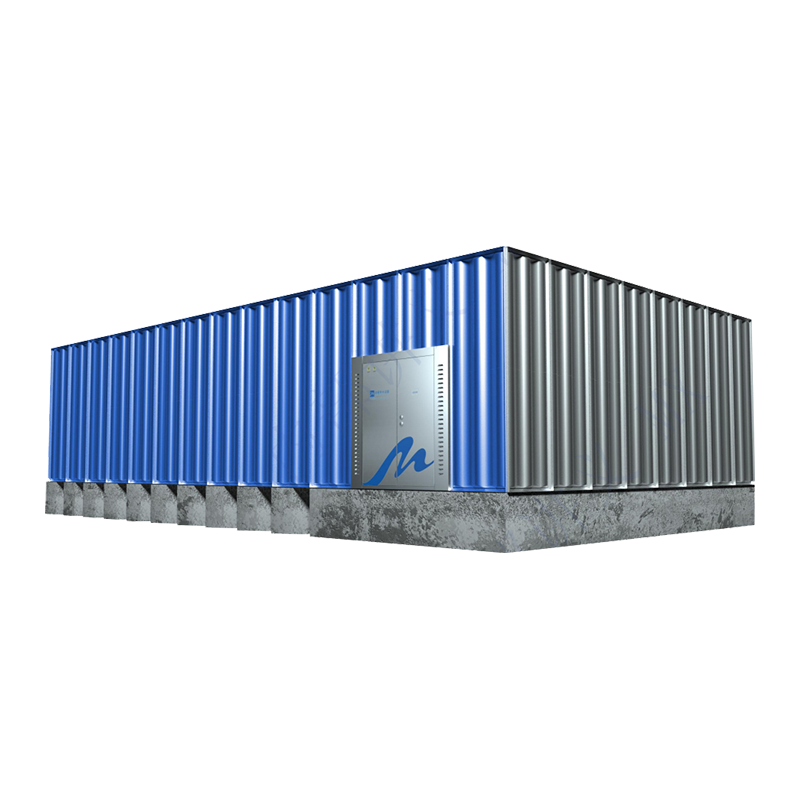

Alternative Naming for Complete System Integration

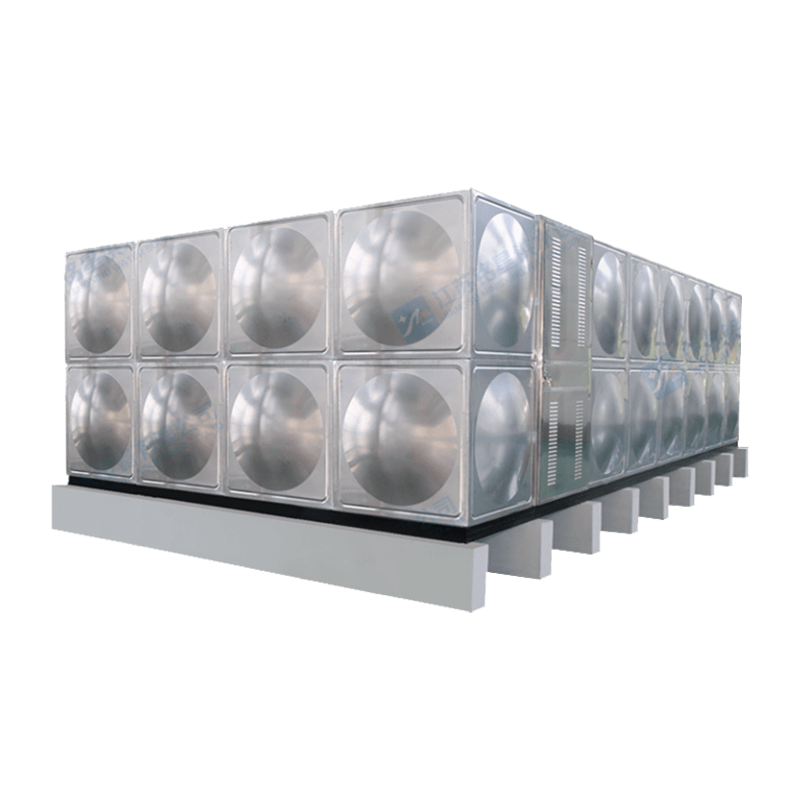

This term is functionally synonymous with the Integrated Prefabricated Pumping Station With Tank. It emphasizes the physical integration of the water storage tank and the pressure boosting/transfer pump system into a single, pre-engineered, factory-assembled module.

The purpose is to provide a single-source, plug-and-play solution where the pump set's suction is drawn directly and optimally from the attached tank, ensuring maximum hydraulic efficiency, rapid deployment, and minimal on-site civil and mechanical work.

Specification Table: Integrated Tank Pump Station

| Configuration | Single Module Combining Tank and Pump Skid |

| Assembly | Factory Built, Skid or Enclosure Mounted |

| Key Benefit | Optimized Suction Head / NPSHa |

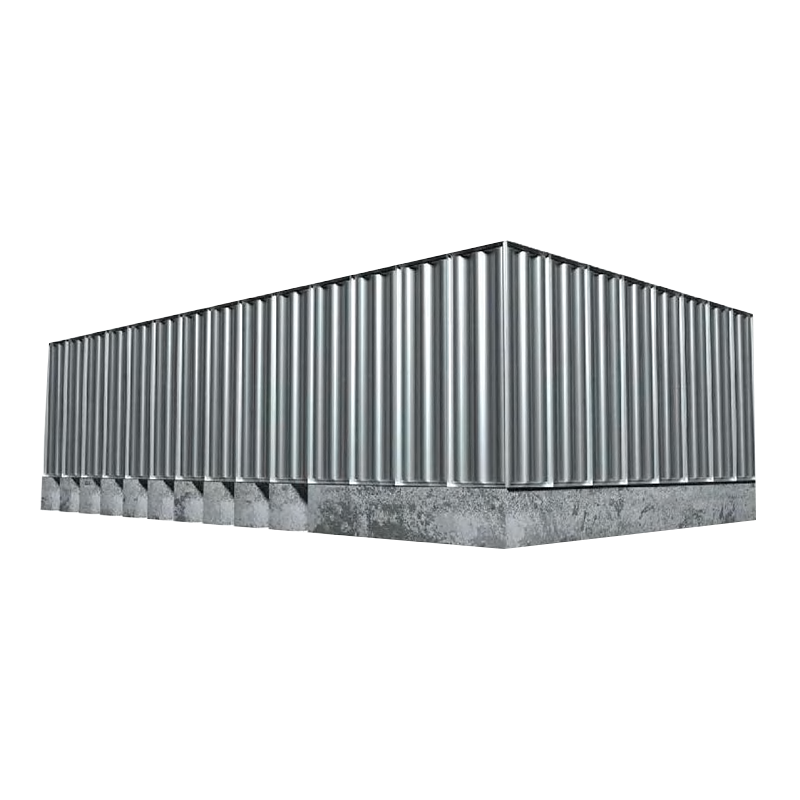

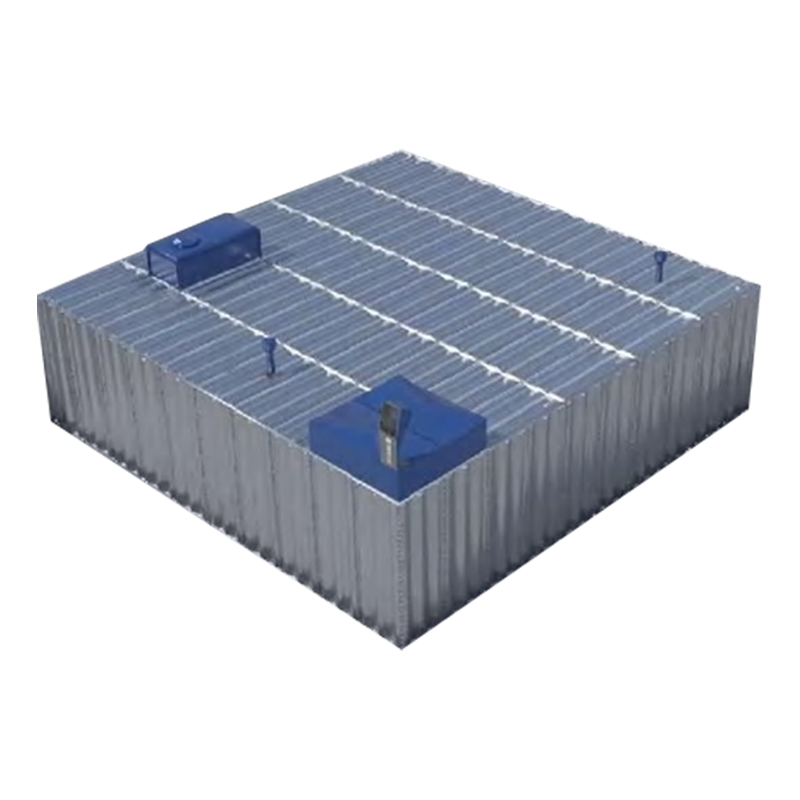

| Material | Corrosion-Resistant Steel Tank (HDG, SS) |

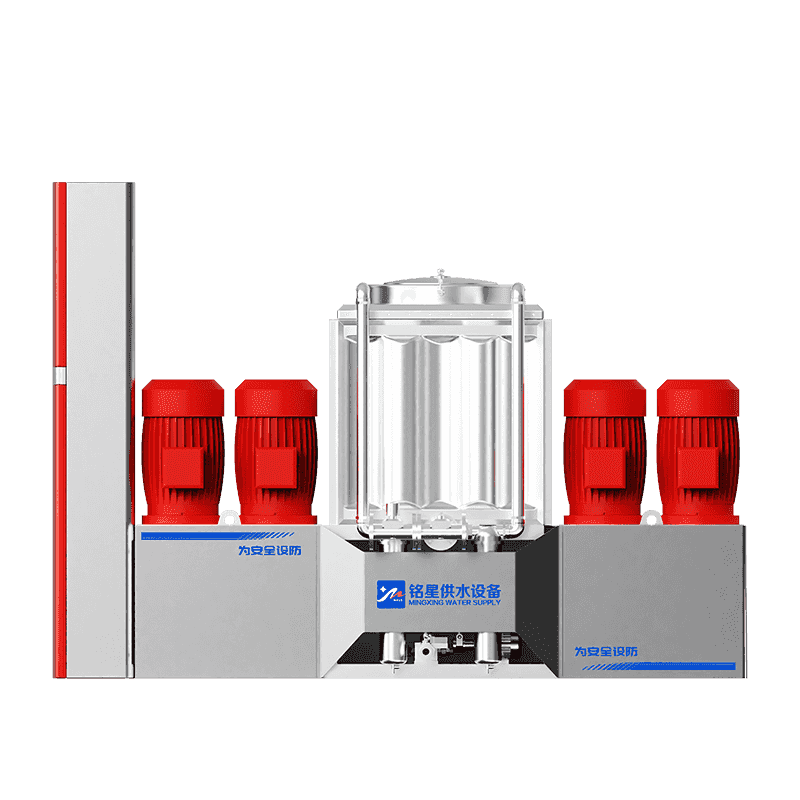

| Pumps & Controls | Integrated VFD/PLC System and Multi-Pump Set |

| Testing | Full System Performance Test (FAT) |

| Applications | Domestic Water Supply, Fire Water Reserve, Transfer |

| Compliance | Relevant Potable Water and Fire Codes |

Application Fields

- Central water supply for campuses, hospitals, and light industrial parks.

- Remote water system installations for mining, oil and gas exploration, or construction camps.

- Any project that requires both large water storage and dedicated boosting capacity in a single unit.

- Utilized as the foundation for the SW Integrated Pumping Station.

- Projects with tight construction schedules and a need for immediate commissioning.

Engineering and Custom Fabrication

Our approach focuses on standardized interfaces between the tank structure and the pump skid to ensure reliable and repeatable assembly quality.

Customization Scope: Specific tank geometry, integration of pre-filtration units, and custom telemetry settings (e.g., Modbus/Profibus) for communication with the client's central control system.

We provide complete operational and maintenance manuals detailing the unified system architecture.