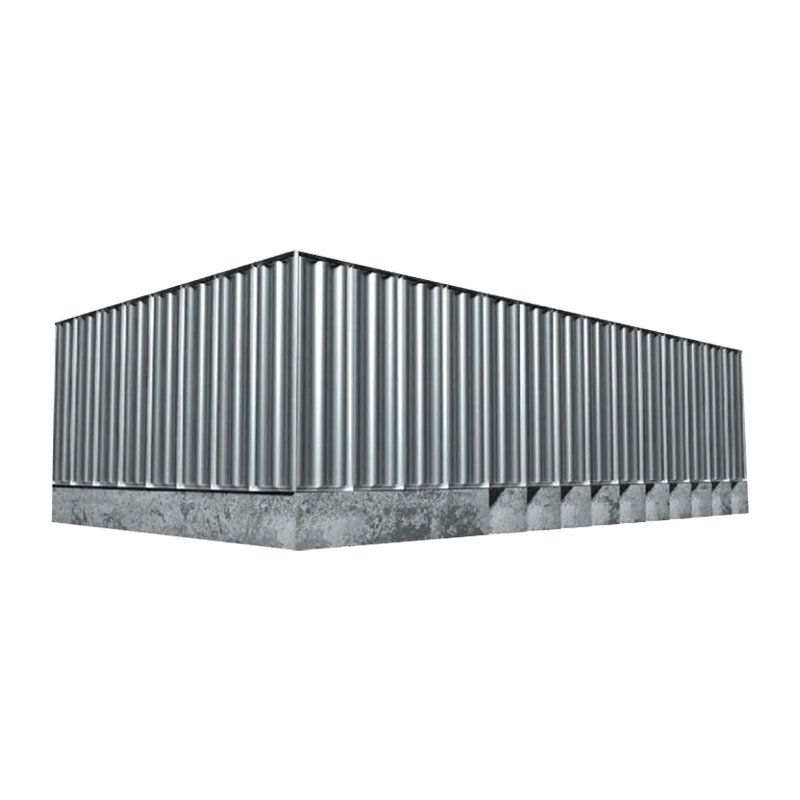

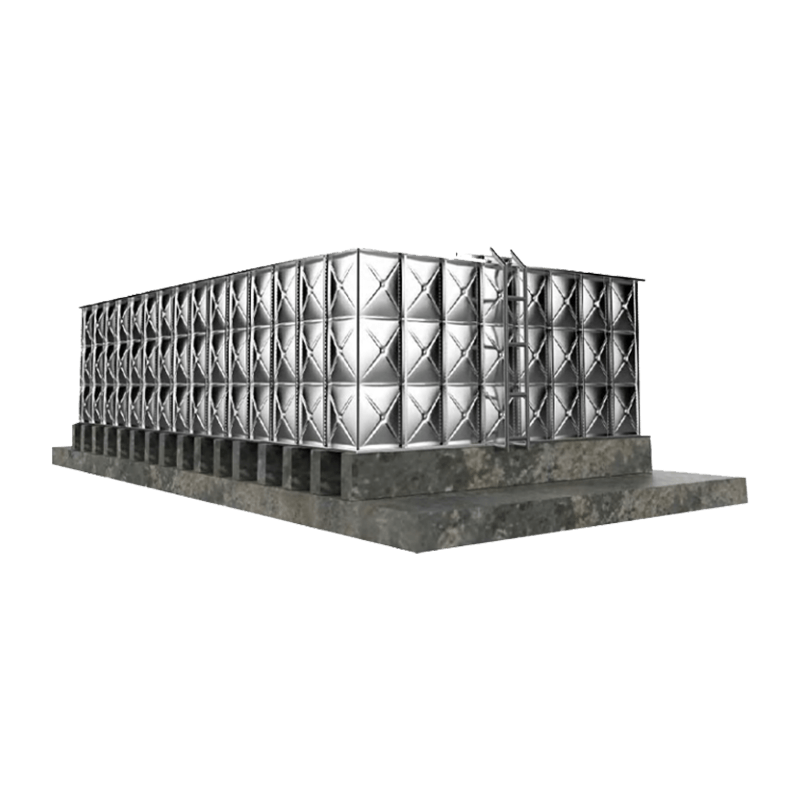

Modular Construction and Enhanced Capacity

The SW Large Module Water Tank is a proprietary sectional tank designed with significantly larger panel sizes than conventional bolted tanks. This large module approach reduces the total number of joints, minimizing reliance on gaskets and bolts, thereby enhancing overall structural integrity and reducing the risk of leakage points.

The tank utilizes high-strength, precision-formed steel plates (Hot-Dip Galvanized or Stainless Steel) and features advanced joint design to resist deformation under hydrostatic pressure. The large modules allow for expedited assembly, significantly reducing the labor hours required on-site, particularly for high-capacity installations.

Specification Table: SW Large Module Water Tank

| Panel Size (Example) | 2.0 m x 2.0 m or Larger (vs. 1 m x 1 m standard) |

| Construction Method | Sectional, Bolted (Internal/External Flanges) |

| Material | Durable HDG Steel or 304/316 Stainless Steel |

| Sealing System | Non-toxic EPDM Rubber Gasket |

| Applicable Height | Up to 6 meters (Standard) |

| Internal Reinforcement | Minimal Internal Tie-Rods Required (Due to large module stiffness) |

| Compliance | Potable Water Standards (e.g., WRAS/NSF equivalent for materials) |

| Installation Time | Reduced by 40% compared to standard sectional tanks |

Application Fields

- High-capacity domestic and fire water reserve storage for new urban developments.

- Bulk water storage for large industrial facilities and factories.

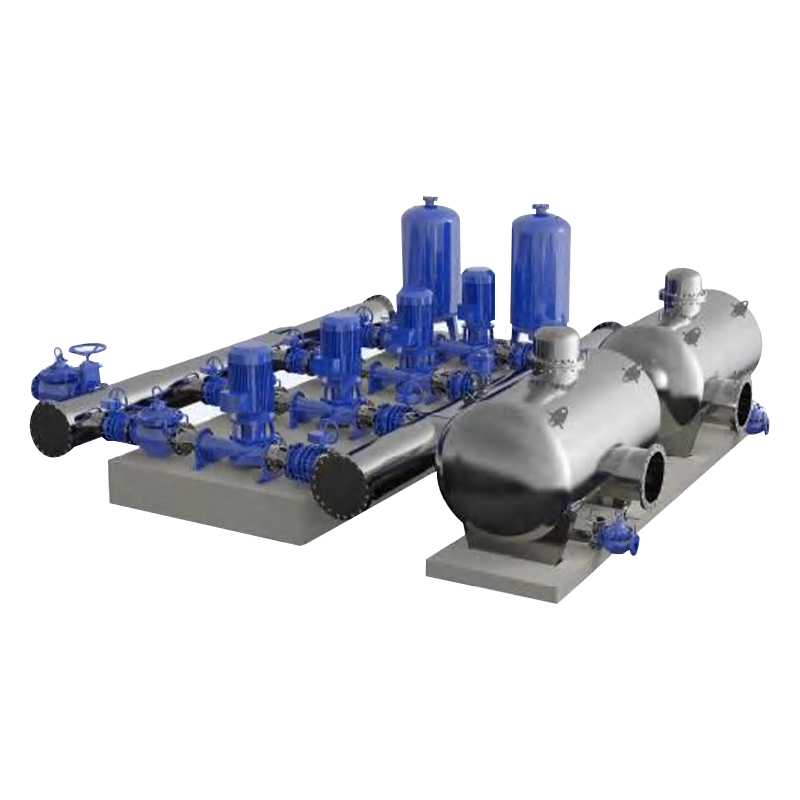

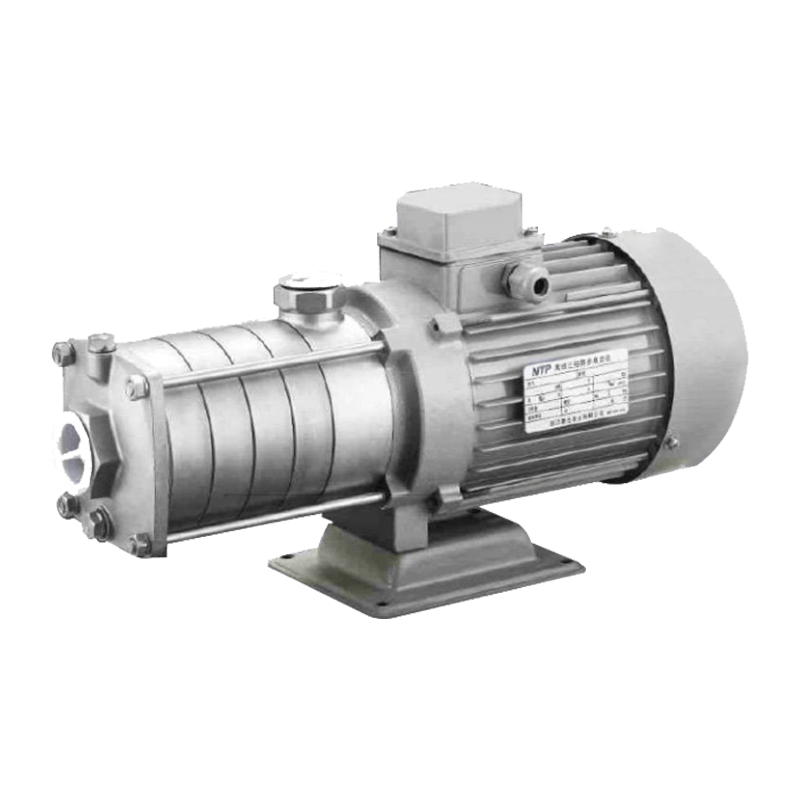

- Integrated into the SW Integrated Pumping Station and Integrated Domestic And Fire Protection Pumping Station.

- Storage of treated wastewater and industrial process fluids.

- Water reserves for remote sites and mining operations requiring large, easily assembled capacity.

Engineering and Custom Fabrication

Panels are precision-formed using multi-ton hydraulic presses, ensuring all bolt holes and rib structures are perfectly aligned for seamless on-site assembly.

Customization Scope: Full range of dimensions (L x W x H) and specialized panel treatments, including dual-compartment designs for domestic and fire water separation, and the integration of internal anti-slosh baffles.

We provide detailed 3D assembly drawings and structural load calculations for the client's foundation engineering.