Deep-Well/Pit Suction and Submerged Operation

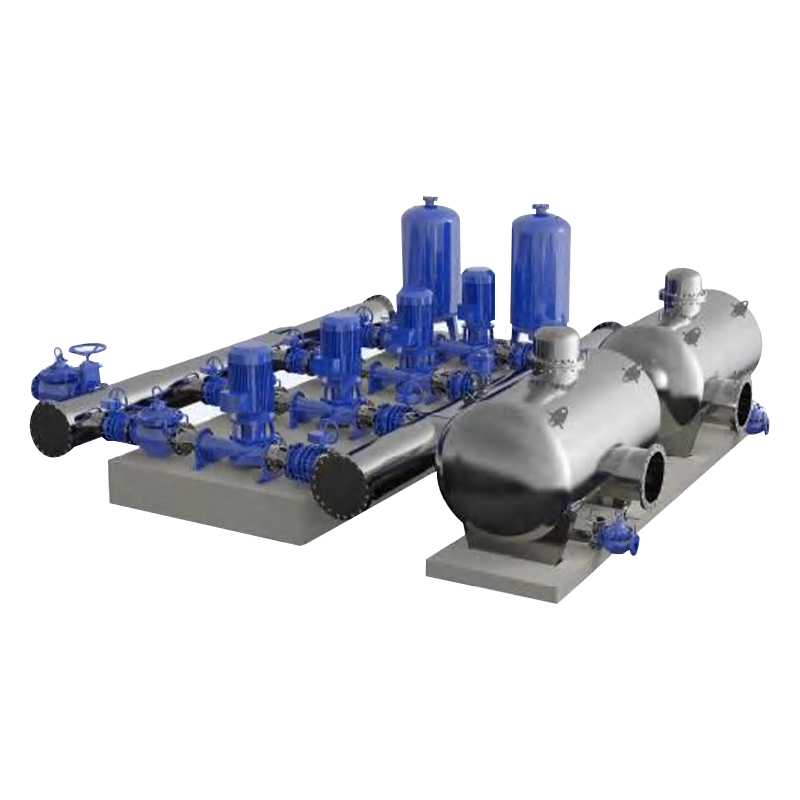

The Vertical Turbine Fire Pump is a specialized vertical multi-stage pump specifically designed for applications where the fire water source is located significantly below the pump room floor (e.g., deep wells, reservoirs, deep pits, or subterranean fire tanks). The impellers are located deep within the water source, submerged in a column pipe, maximizing the available suction head (NPSHa).

This pump eliminates the suction lift limitations of standard horizontal pumps. The driver (electric motor or diesel engine) remains above ground, connected to the submerged impellers by a long line shaft, ensuring that the pump can start instantly without priming issues.

Specification Table: Vertical Turbine Fire Pump

| Configuration | Vertical, Driver Above Ground, Impellers Submerged |

| NFPA Compliance | UL Listed, FM Approved, NFPA 20 Certified |

| Suction Condition | Below Grade/Water Level (Deep Lift Capability) |

| Application Head | High Head (Similar to Multi-Stage), Range Varies by Depth |

| Components | Head Assembly, Column Pipe, Discharge Head, Bowl Assembly |

| Driver Type | Electric Motor or Vertical Diesel Engine |

| Lubrication | Oil-Lubricated or Water-Lubricated Bearings |

| Test Requirement | 150% Rated Flow at 65% Rated Head Min. |

Application Fields

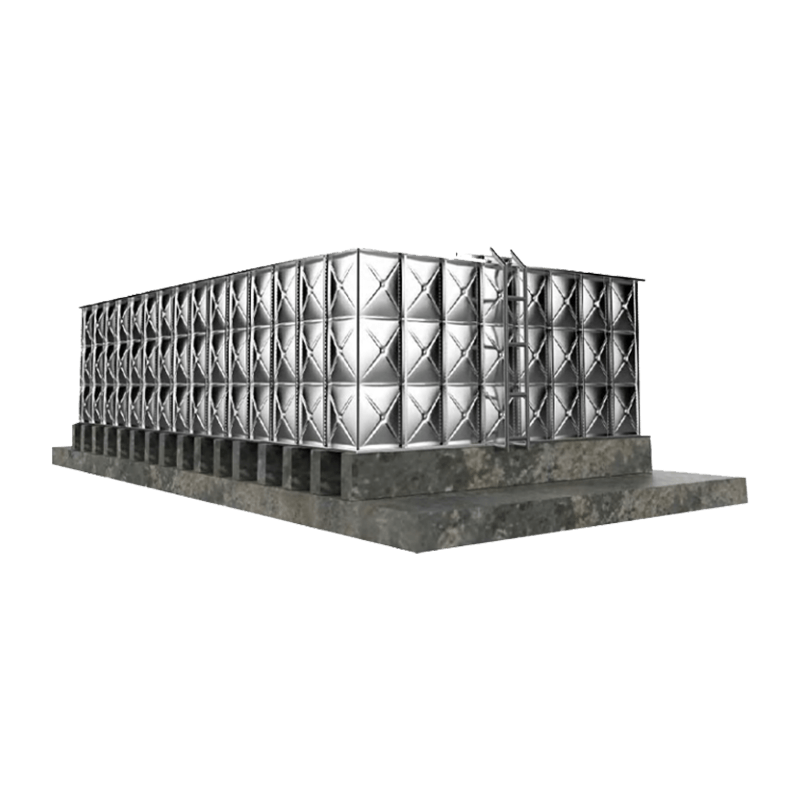

- Drawing fire water from underground storage tanks, reservoirs, or large cisterns with deep minimum water levels.

- Fire protection for industrial facilities along rivers or lakes where the water level fluctuates significantly.

- Integrated into the Mingxing Buried Integrated Fire Pump Station for high-head, concealed fire water boosting.

- Seawater or raw water fire systems where suction lift is beyond the capability of a split case pump.

- Remote sites utilizing groundwater wells as the primary fire source.

Engineering and Custom Fabrication

We perform torsional vibration analysis to select the correct line shaft material and column pipe length, ensuring the system operates smoothly across the entire NFPA flow curve.

Customization Scope: Specific depth setting of the bowls (for varying water levels), custom discharge head design for pipe routing, and integration of specialized non-reverse ratchets to prevent backspin upon shutdown.

We provide detailed installation instructions for the column pipe assembly and driver alignment.