Space-Saving, High-Head Fire Suppression

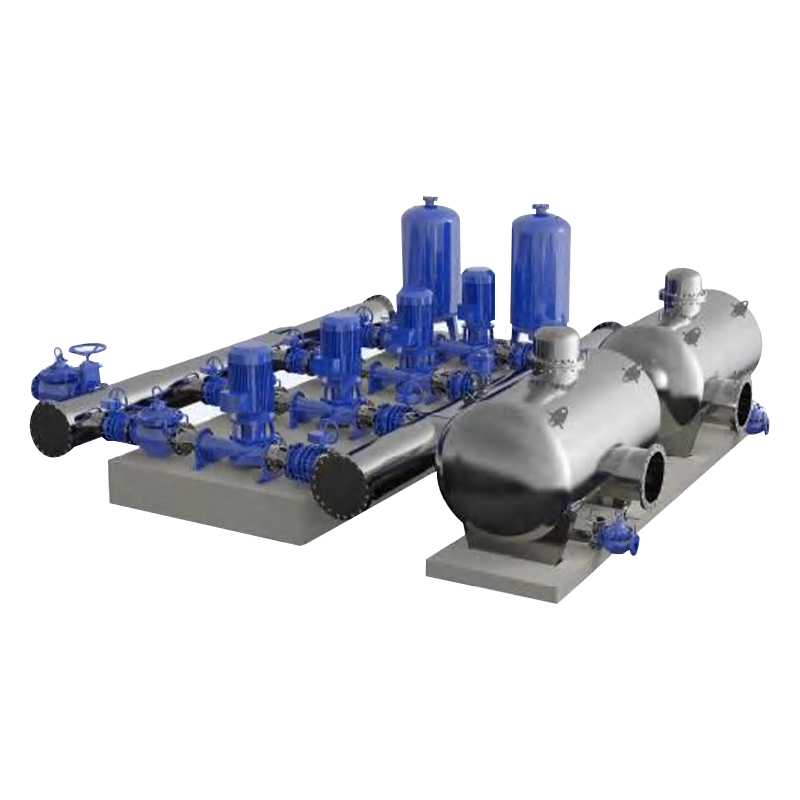

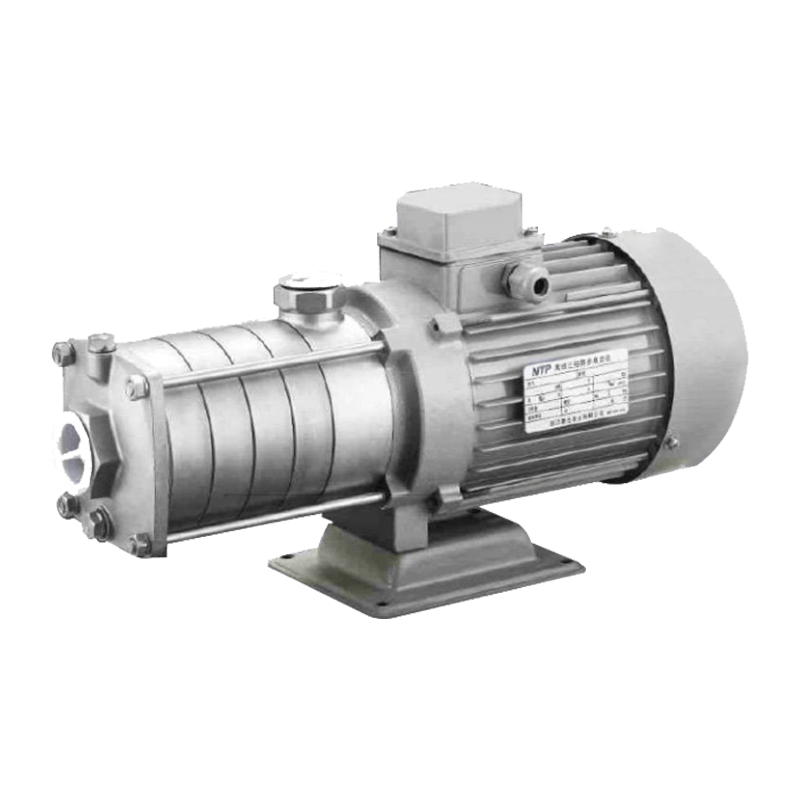

Vertical Multi-Stage Fire Pumps are centrifugal pumps specifically engineered to deliver high pressure (head) for fire suppression systems in tall buildings, utilizing multiple impellers stacked vertically on a single shaft. Their vertical orientation offers a significantly smaller footprint than horizontal split case pumps for the same head and flow, crucial for compact pump rooms.

As with all fire pumps, they are subject to NFPA 20 and must be UL Listed or FM Approved. The multi-stage design ensures stable, high-pressure output, essential for reaching the top floors of high-rise structures or powering high-pressure systems like the High Pressure Water Mist System.

Specification Table: Vertical Multi-Stage Fire Pump

| Configuration | Vertical, Close-Coupled or Shaft-Driven |

| NFPA Compliance | UL Listed, FM Approved, NFPA 20 Certified |

| Head Generation | High Head (Up to $300 \ meters \text{+} $ or 435 PSI) |

| Footprint | Minimal Floor Space Required (Vertical Orientation) |

| Driver Type | Electric Motor or Vertical Diesel Engine |

| Casing Material | Cast Iron, Bronze Fitted, or Stainless Steel |

| Sealing | Packed Stuffing Box or Mechanical Seal (Specific to Fire Duty) |

| Test Requirement | 150% Rated Flow at 65% Rated Head Min. |

Application Fields

- High-rise and super-tall commercial and residential buildings requiring high-pressure fire risers.

- Compact pump rooms in basements or utility cores where space is severely restricted.

- Pressure boosting for specialized high-pressure fire systems (e.g., water mist).

- Used as the booster pump in the Integrated Prefabricated Fire Pump Station for high-head requirements.

- Fire suppression systems requiring suction from a deep well or reservoir (Vertical Turbine design).

Engineering and Custom Fabrication

We employ precision balancing of all impellers and the entire rotating assembly to ensure minimal vibration, which is critical for the long life of a high-speed vertical machine.

Customization Scope: Full range of UL/FM certified ratings (flow and head). Specific flange sizes and ratings, custom motor voltages, and integration with the Intelligent Fire-fighting monitoring system for remote readiness checks.

Every pump undergoes a certified hydrostatic and performance test at the factory.